Inlet distortion constraint device and centrifugal compressor provided with same

A technology of centrifugal compressors and restraint devices, which is applied to the parts of pumping devices for elastic fluids, mechanical equipment, non-variable pumps, etc., and can solve the problems of compressor efficiency attenuation, aggravated shaft system fluctuations, complex construction, etc. problem, to achieve the effect of improving reliability, reducing impact impact, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

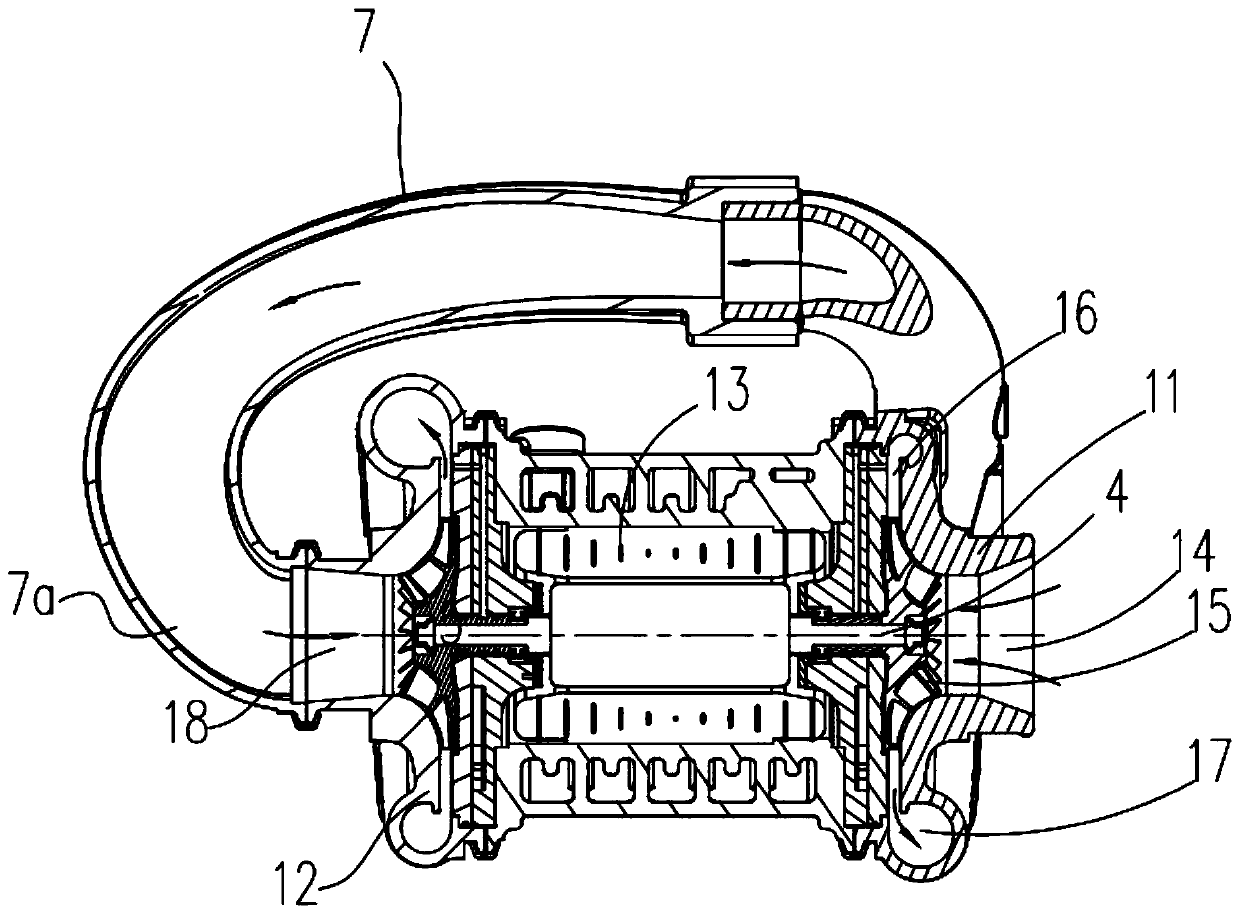

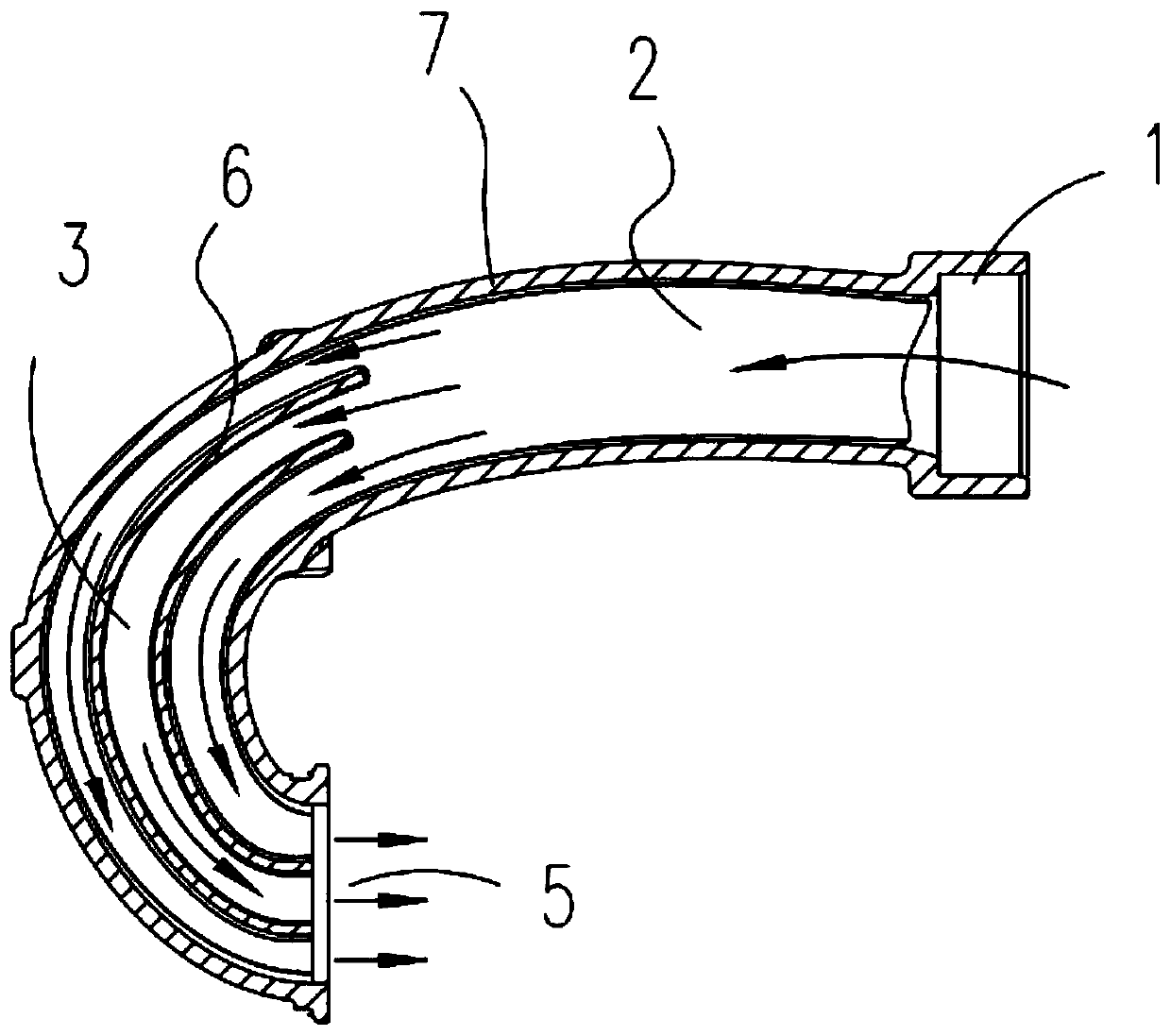

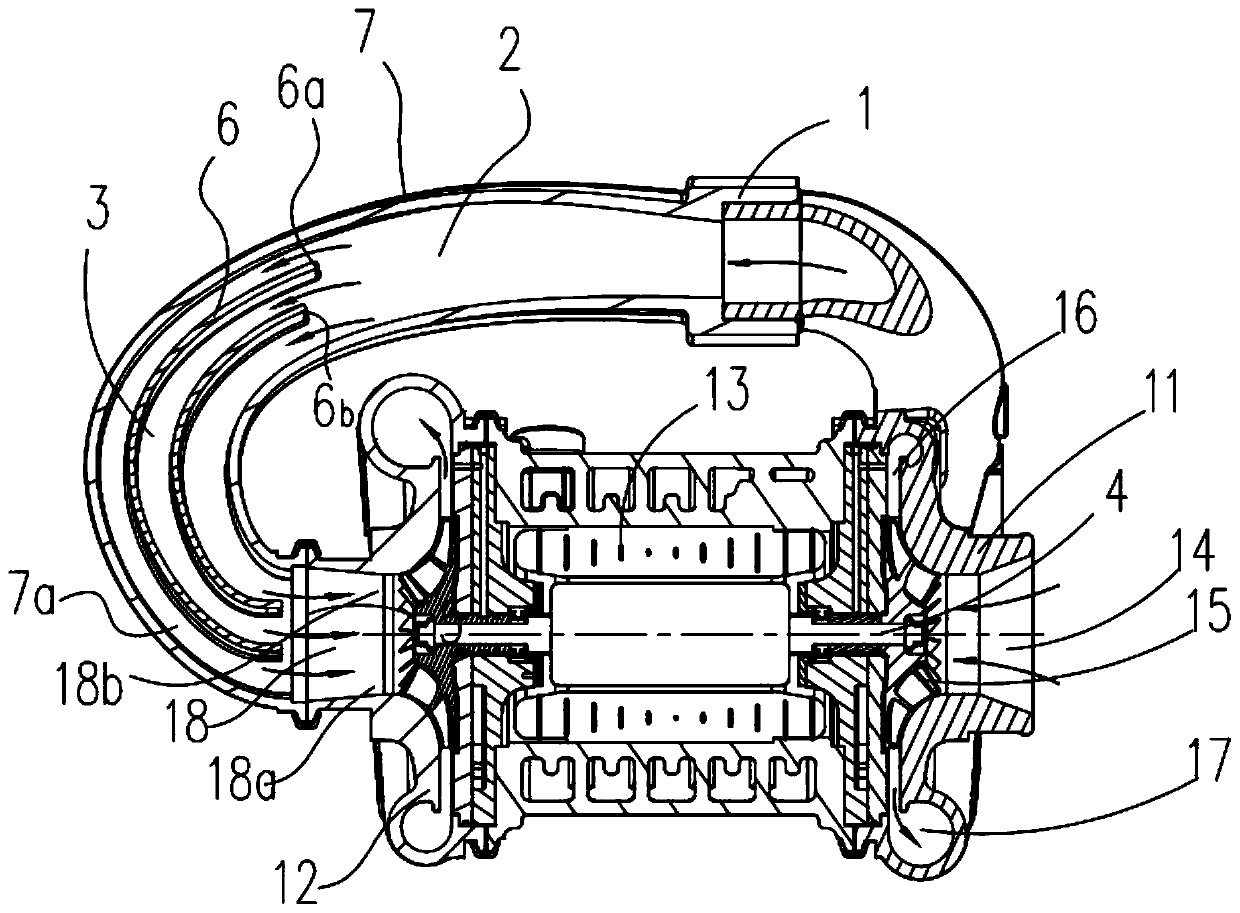

[0040] Such as Figure 1 to Figure 4 as well as Figure 10 As shown, the intake distortion restriction device and the centrifugal compressor with the device include a guide tube, and the inner cavity of the guide tube 7 is provided with a stabilizing plate 6 for rectifying the turbulent air flow along its guide direction, and the centrifugal compressor The low-pressure stage compressor casing flow channel 17 of the low-pressure stage air outlet is connected to the intake end of the guide pipe 7, and the air outlet end of the guide pipe 7 is connected to the high-pressure stage air inlet of the centrifugal compressor.

[0041] The inner cavity of the guide tube 7 is divided into a drainage channel 2 and a diversion channel 3 in sequence along the air intake direction, and the stabilizing plate 6 is located in the diversion channel 3 .

[0042] Drainage channel 2, the function of the drainage channel 2 is to evenly distribute the pressurized gas passing through the gas inlet part...

Embodiment 2

[0064] Such as Figure 5 As shown, the difference between this embodiment and the first embodiment lies in the shape of the flow stabilizing plate, which includes two juxtaposed plate bodies that gradually change with the shape of the draft tube.

Embodiment 3

[0066] Such as Figure 6 As shown, the difference between this embodiment and Embodiments 1 and 2 lies in the shape of the stabilizing plate. The stabilizing plate includes two plates that gradually change with the shape of the draft tube, and the two plates along the longitudinal section of the air inlet The direction is set in a criss-cross pattern.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com