Power cycle acceleration test device and control method of mmc sub-module

A power cycle and accelerated test technology, applied in the field of power transmission and distribution, can solve the problems that the aging characteristics of sub-modules and consistent test results cannot be obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

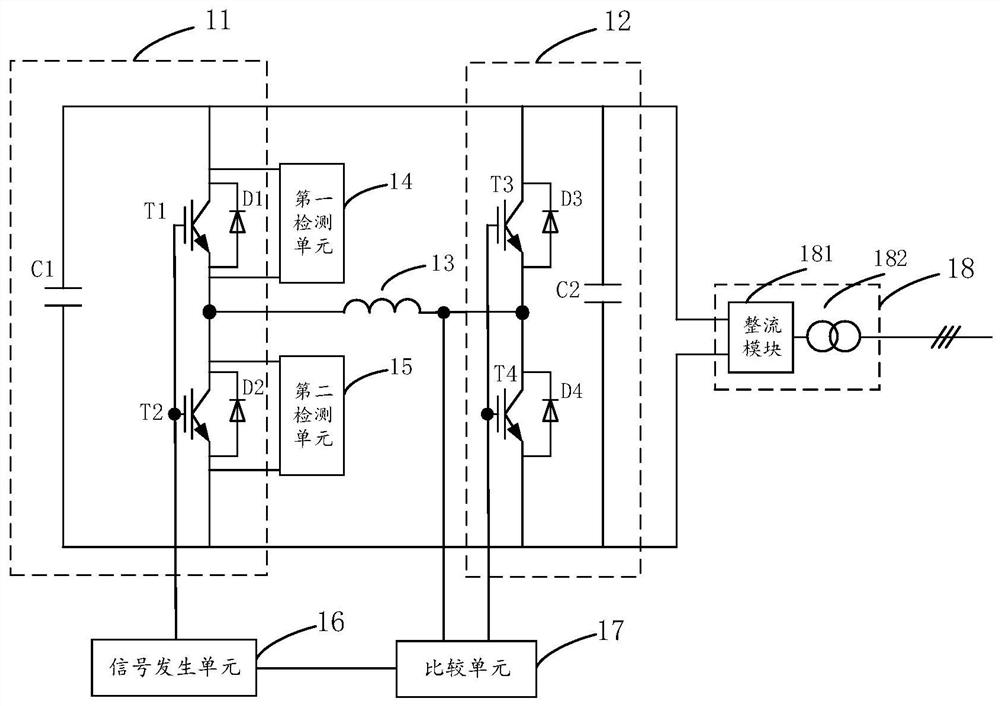

[0040] see figure 1, is a schematic structural diagram of an accelerated power cycle test device for an MMC sub-module provided in Embodiment 1 of the present invention. The accelerated power cycle test device for the MMC sub-module includes a tested unit 11, an accompanying test unit 12, and a reactance unit 13 , a first detection unit 14, a second detection unit 15, a signal generation unit 16 and a comparison unit 17;

[0041] The unit under test 11 is electrically connected in parallel to the two ends of the test unit 12; the first end of the reactance unit 13 is connected to the first end of the unit under test 11, and the second end of the reactance unit 13 End is connected with the first end of described accompanying test unit 12; Described first detection unit 14, described second detection unit 15 are all electrically connected with described tested unit 11; The first end of described signal generating unit 16 It is connected with the second end of the unit under tes...

Embodiment 2

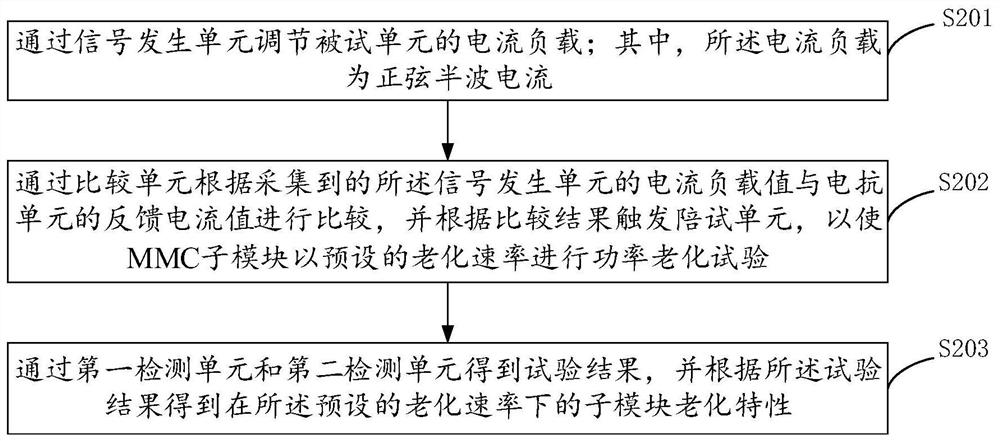

[0064] see figure 2 , is a schematic flowchart of a power cycle acceleration control method for an MMC sub-module provided in Embodiment 2 of the present invention, and the method includes the following steps S201 to S203.

[0065] S201. Adjust the current load of the unit under test through the signal generating unit; wherein, the current load is a half-sine wave current.

[0066] It should be noted that the signal generation unit 16 applies intermittent sinusoidal half-wave current loads with adjustable amplitude and period to the IGBT devices in the sub-modules according to the actual operating conditions of the modular multilevel converter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com