Adaptive dead zone setting method for petrochemical process alarm system based on multi-source data

An alarm system, multi-source data technology, applied in general control systems, control/regulation systems, program control and other directions, can solve the problems of inaccurate alarm information and poor security, achieve accurate alarm information, reduce shock alarms, and reduce errors. The effect of the reporting rate and the false negative rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

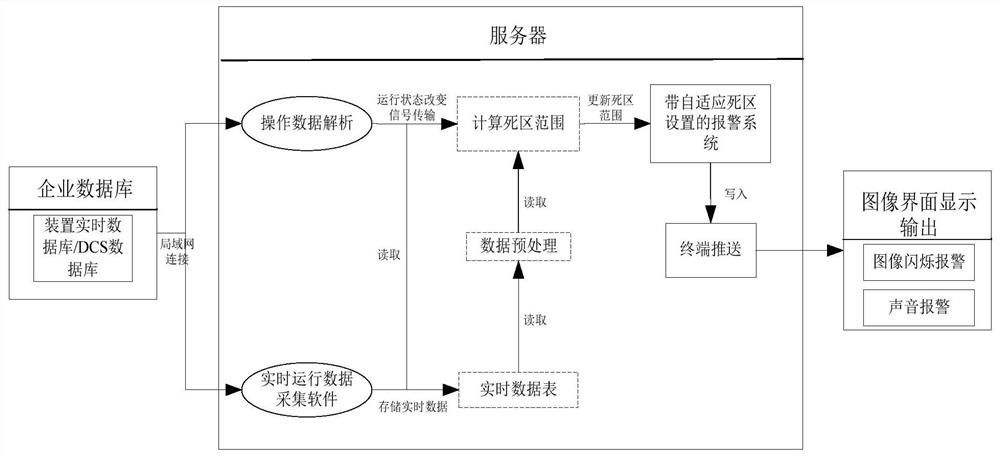

[0016] Embodiments of the present invention consist of figure 1 As shown, it includes the construction of real-time collection platform for multi-source data of the device, data preprocessing, analysis of operation ledger, calculation of adaptive dead zone range, and development of alarm system with adaptive dead zone setting.

[0017] Real-time data acquisition platform construction: According to the data acquisition interface provided by the enterprise (the sampling frequency in the real-time database can reach 1 time / minute), an OPC DA server framework implemented by VC++ programming is used to collect and run from the control system of the device or the real-time database of the enterprise Real-time data, refresh the real-time data table of the server, and store the real-time data in the historical data table of each parameter in time series. Each variable saves 10,000 data in the real-time data table of the server, and the real-time database is updated every time the runn...

Embodiment 2

[0028] Embodiments of the present invention consist of figure 1 As shown, it includes the construction of real-time collection platform for multi-source data of the device, data preprocessing, analysis of operation ledger, calculation of adaptive dead zone range, and development of alarm system with adaptive dead zone setting.

[0029]Real-time data acquisition platform construction: According to the data acquisition interface provided by the enterprise (the sampling frequency in the real-time database can reach 2 times / minute), an OPC DA server framework implemented by VC++ programming is used to collect and run from the control system of the device or the real-time database of the enterprise Real-time data, refresh the real-time data table of the server, and store the real-time data in the historical data table of each parameter in time series. Each variable saves 10,000 data in the real-time data table of the server, and the real-time database is updated every time the runn...

Embodiment 3

[0040] Embodiments of the present invention consist of figure 1 As shown, it includes the construction of real-time collection platform for multi-source data of the device, data preprocessing, analysis of operation ledger, calculation of adaptive dead zone range, and development of alarm system with adaptive dead zone setting.

[0041] Real-time data acquisition platform construction: According to the data acquisition interface provided by the enterprise (using the OPC DA specification to collect data from the DCS system can reach a frequency of 1 time / second), an OPC DA server framework implemented by VC++ programming, slave device control The system or enterprise real-time database collects and runs real-time data, refreshes the real-time data table of the server, and stores the real-time data in time series into the historical data table of each parameter. Each variable saves 10,000 data in the real-time data table of the server, and the real-time database is updated every ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com