Button type high-voltage remote control switch for distribution box

A remote control, distribution box technology, applied in electrical switches, substation/switch layout details, switchgear and other directions, can solve the problems of large floor space, interference of operators and guardians, and high error rate, and improve the safety factor , to achieve the effect of diversity and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

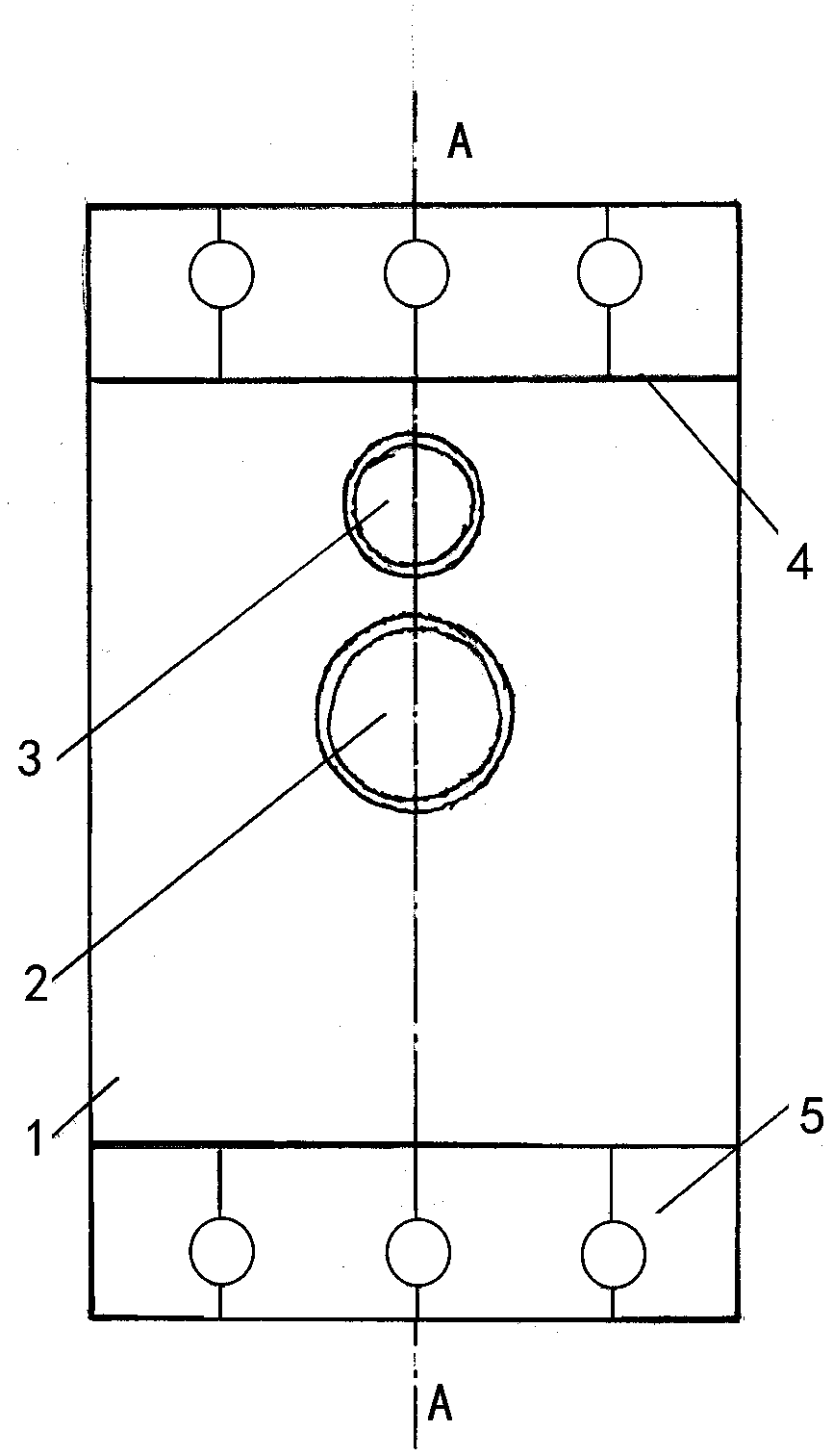

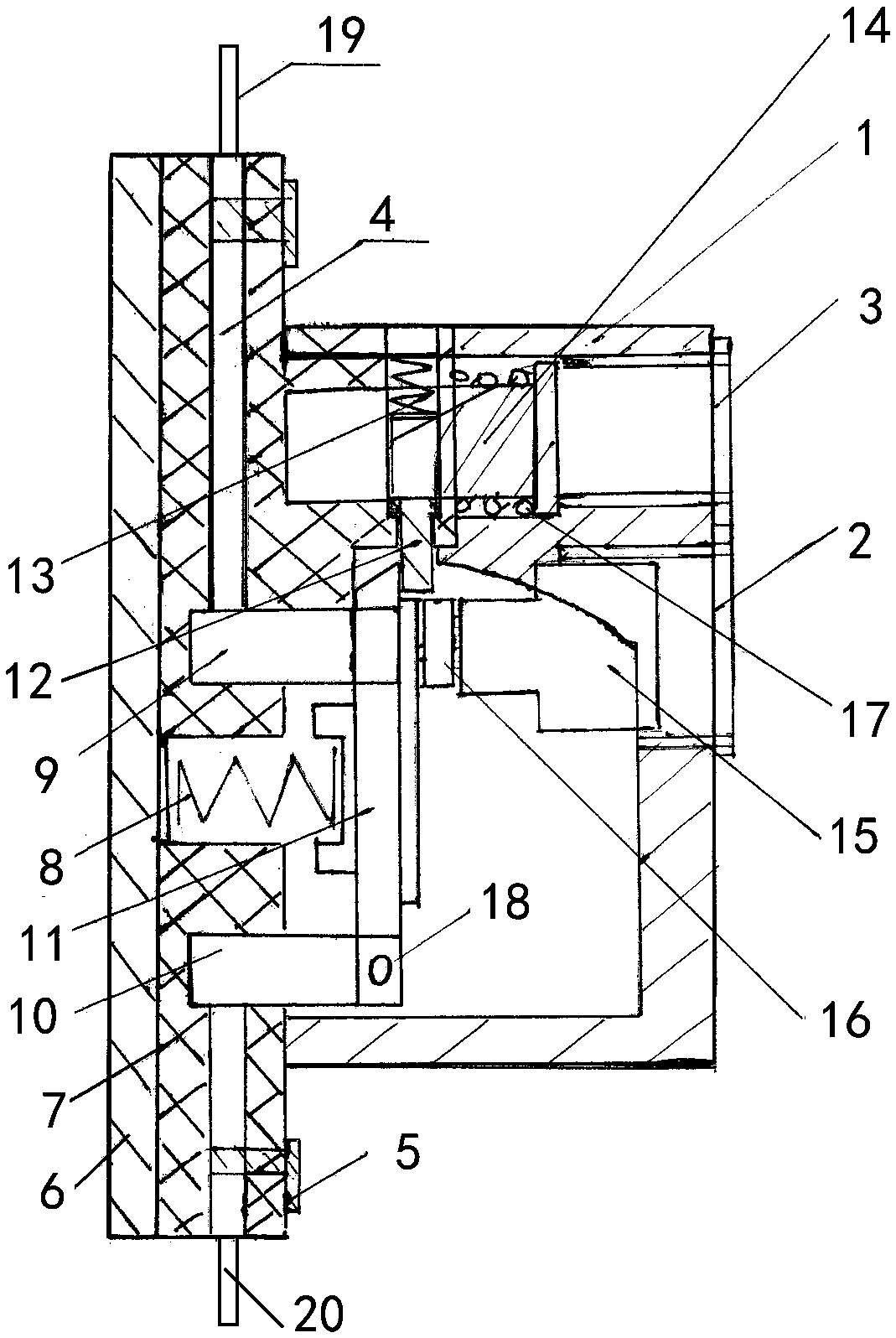

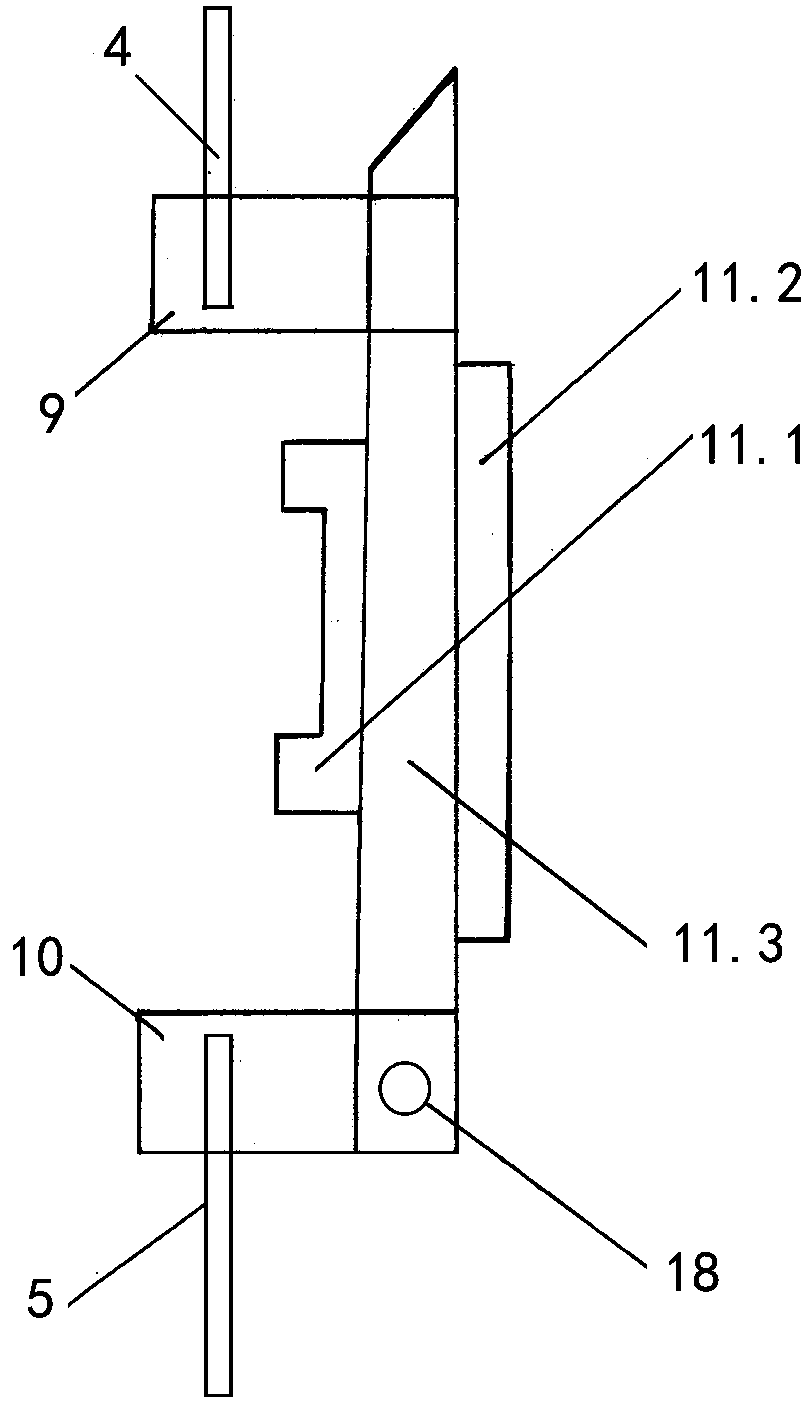

[0033] Embodiment 1, with reference to attached Figure 1-2 , a button-type high-voltage remote control switch for a power distribution box mentioned in the present invention, its technical solution is: including an insulating shell 1, an access button installer 2, a circuit breaker button installer 3, a power supply terminal 5, and an electric terminal 5. Installation base plate 6, switch carrier 7, circuit disconnection spring 8, circuit disconnection movable knife edge 9, circuit disconnection fixed knife edge 10, opening and closing guillotine knife 11, circuit closing pin 12, circuit closing spring 13, circuit disconnecting actuator 14, circuit closing actuator 15, circuit return spring 17, fixed rotating shaft 18, switch carrier 7 is installed on one side of installation base plate 6, the upper side of switch carrier 7 is installed the power supply terminal 5 of external power supply line 19, and the lower side is installed Set the power terminal 5 of the external electr...

Embodiment 2

[0049] Embodiment 2, the difference between the present invention and embodiment 1 is:

[0050] Refer to attached Figure 13 , the access button installer 2 and the disconnect button installer 3 both use pneumatic remote buttons, including button cylinder b1, press down piston b2, gas pipeline b3, pneumatic reversing valve b4, and the inner cavity of the button cylinder b1 is provided with a lower Press the piston b2, the outside of the button cylinder b1 is connected to the remote pneumatic reversing valve b4 through the air pipeline b3, the pneumatic reversing valve b4 is provided with a reversing handle, and the access button installer 2 and The on-off of the break button installer 3.

[0051] The difference between the using method of the embodiment of the present invention and the using method of embodiment 1 is:

[0052] Specifically, when the pneumatic remote control circuit breaker is used, the compressed gas enters the button cylinder b1 in the circuit breaker butto...

Embodiment 3

[0054] Embodiment 3, the difference between the present invention and embodiment 1 is:

[0055] Refer to attached Figure 14 , the access button installer 2 and the disconnection button installer 3 both use electric remote buttons, and the two have the same structure; Figure 13Taking the circuit breaker button installer 3 as an example, it includes a coil pressing sleeve a1, a coil fixing sleeve a2, a coil a3, a current limiting resistor a4, an external power supply a5, an armature a6, and an operation switch a7. There is a coil pressure sleeve a1 at the end, an armature a6 is provided in the inner cavity of the coil fixing sleeve a2, and a coil a3 is provided outside the armature a6, and is connected to the operation switch a7, the current limiting resistor a4 and the external power supply a5 through wires to form a remote electric circuit. Control operation on and off.

[0056] The difference between the using method of the embodiment of the present invention and the usin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com