Method of preparing malt based beverage using fermentable sugar solution obtained from starch source other than malt and brewing system for preparing malt based beverage according to that method

A technology of maltose amylase and fermented sugar, which is applied in the field of beer and can solve problems such as the impact of brewing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

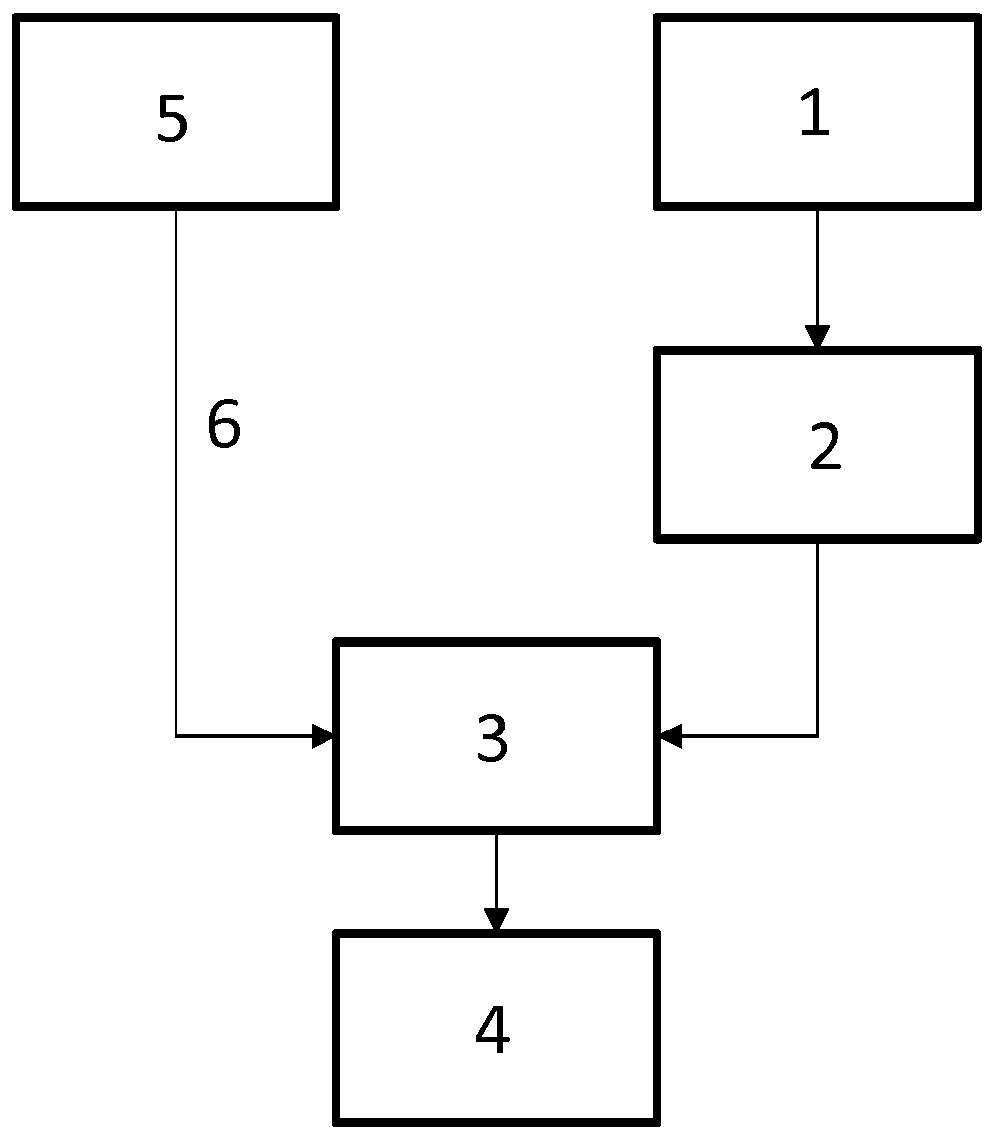

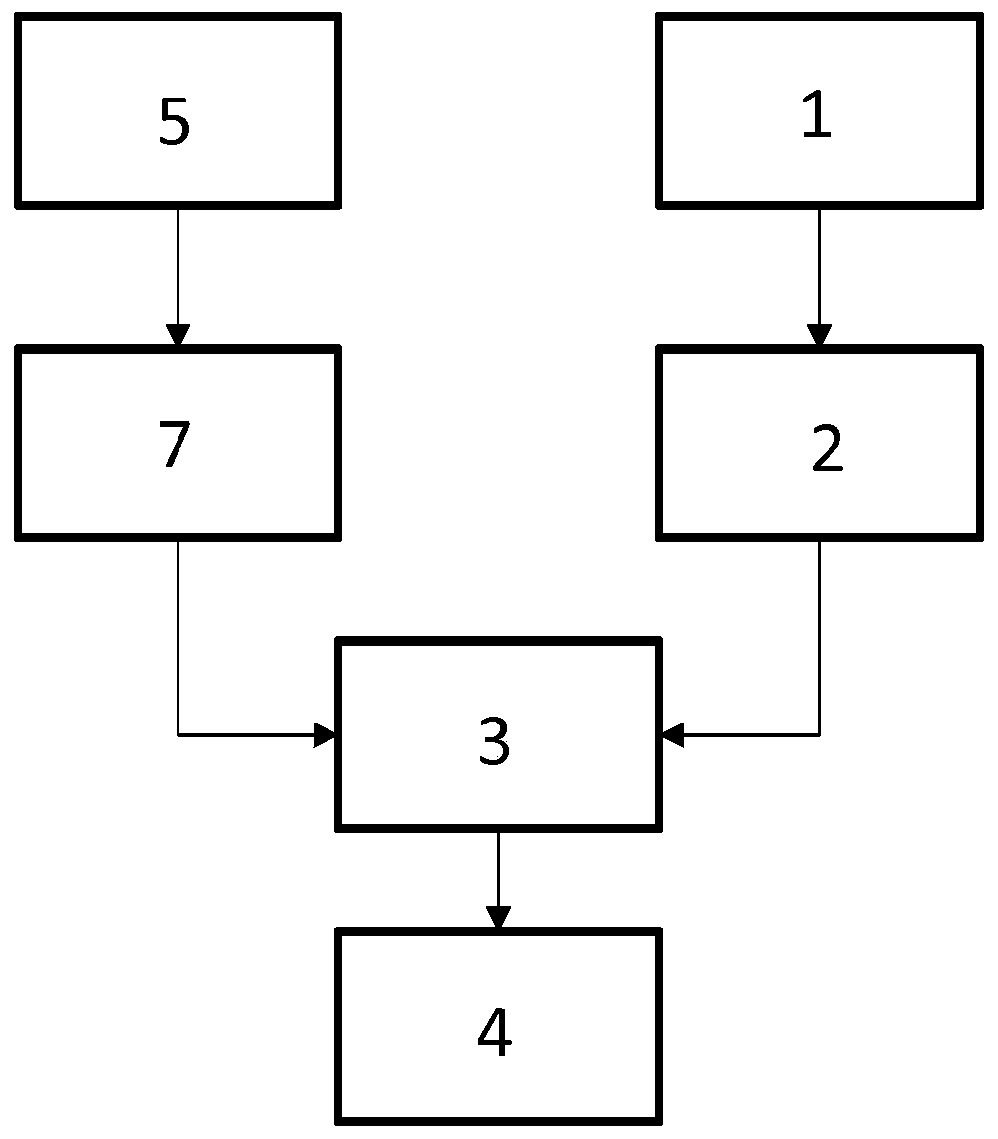

Method used

Image

Examples

Embodiment 2

[0057] As a second example, coarse rice flour was used as a starch source. The meal was hydrated in water at about 60°C to obtain a starch slurry. The mixture is then heated at 60°C to 70°C, preferably 65°C, with a mixture comprising β-amylase activity (preferably maltogenic amylase), α-amylase activity, pullulanase activity and optionally α-amyloglucosidase The active enzyme mixture (eg Ceremix Flex) treatment lasted 20 minutes, after which the temperature was raised to 72°C over a period of 20 minutes to allow gradual gelatinization of the starch. Subsequently, the temperature of the slurry was raised to 80°C and held at this temperature for about 15 minutes. The resulting saccharified starch solution can be used in the method according to the invention for preparing malt-based beverages, in particular beer, as a fermentable sugar solution by addition to the wort pot (wort boiling step). In this example, both Ceremix Flex and Thermamyl SCDS were added at 3000 ppm and 300 p...

Embodiment 3

[0060] As a third example, corn meal was used as the starch source. The meal was hydrated in water at about 60°C to obtain a starch slurry. The mixture is then heated at 60°C to 70°C, preferably 65°C, with a mixture comprising β-amylase activity (preferably maltogenic amylase), α-amylase activity, pullulanase activity and optionally α-amyloglucosidase Active enzyme mixture (eg Ceremix Flex and optionally Thermamyl SCDS) treatment lasts 60 minutes. The temperature of the slurry was then raised to 80°C and held at this temperature for about 40 minutes. The resulting saccharified starch solution can be used in the method according to the invention for preparing malt-based beverages, in particular beer, as a fermentable sugar solution by addition to the wort pot (wort boiling step). In this example, both Ceremix Flex and Thermamyl SCDS were added at 3000 ppm and 300 ppm, respectively.

[0061] Analysis of the resulting saccharified starch showed that more than 90% of the sugars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com