Freezing pre-processing device for aquatic products

A technology for freezing pre-treatment and aquatic products, which is applied in the direction of freezing/cooling preservation of meat/fish, food preservation, climate change adaptation, etc. It can solve problems such as inconvenient distinction and uneven spraying of salt water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

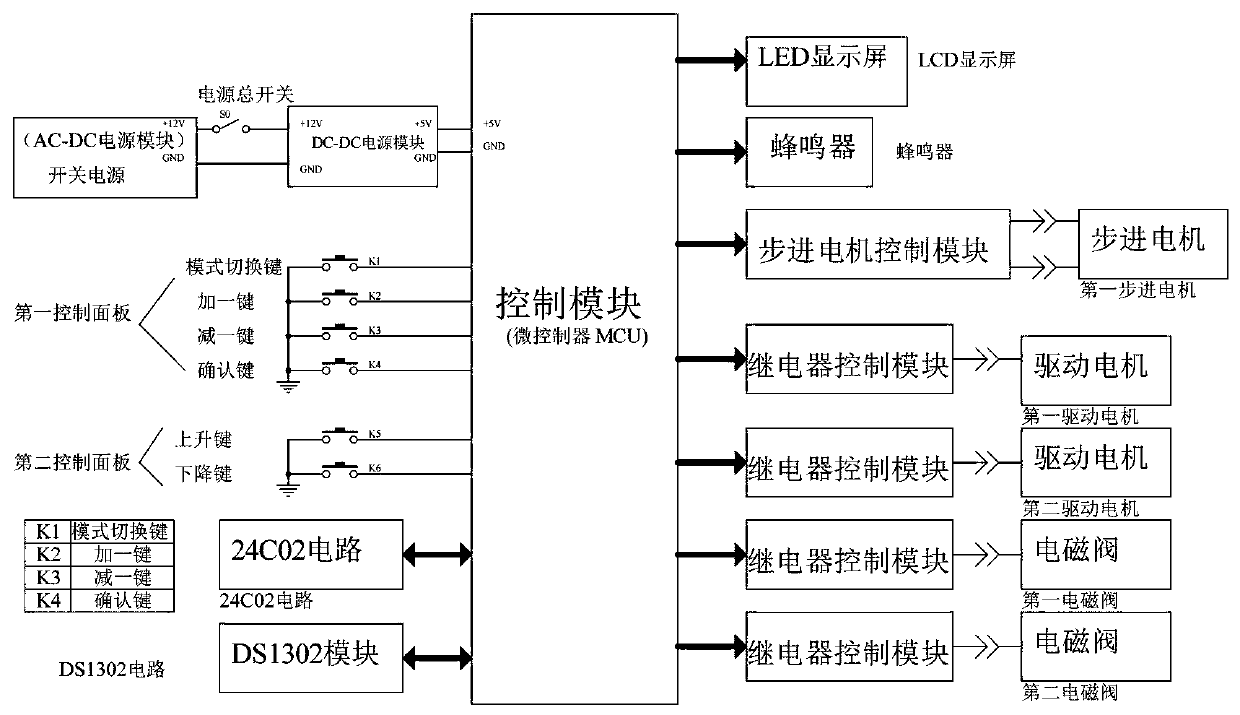

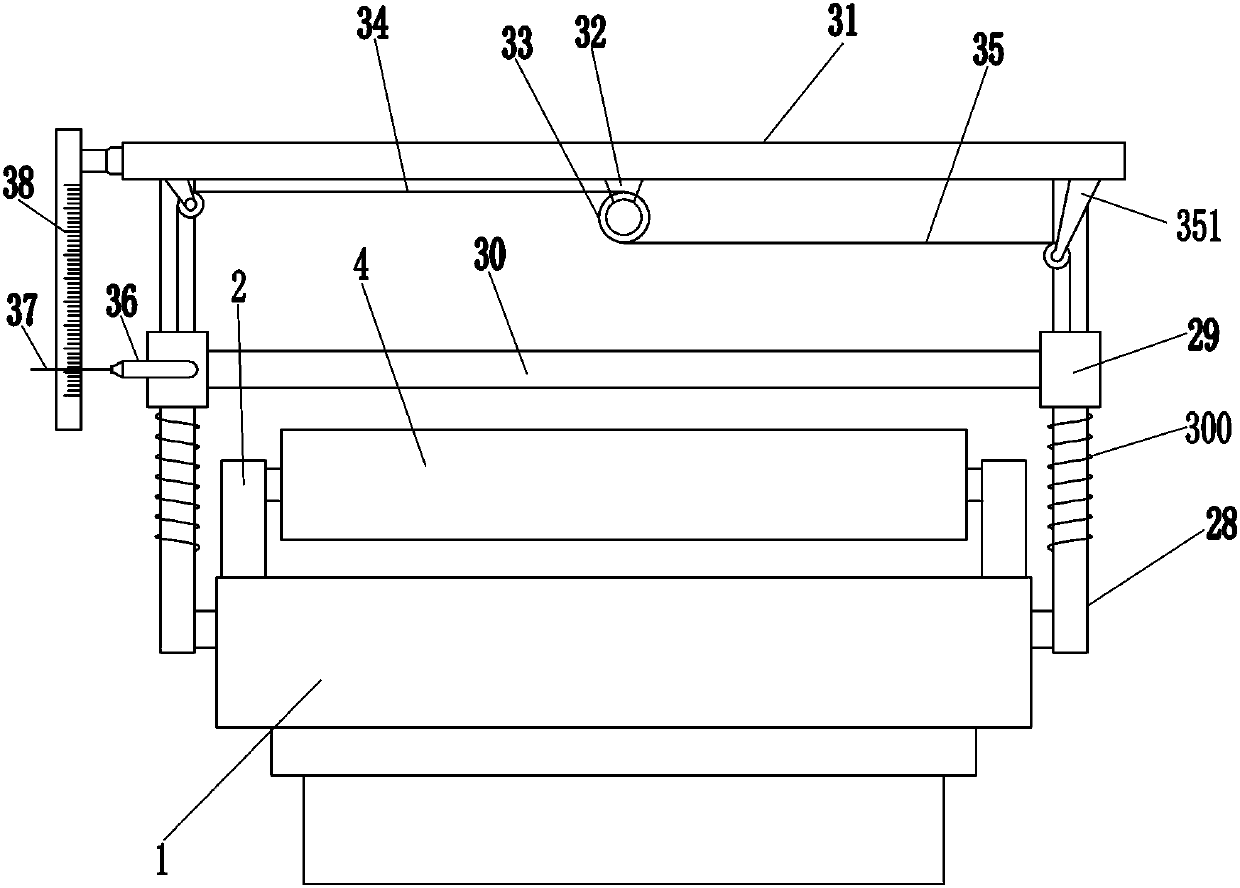

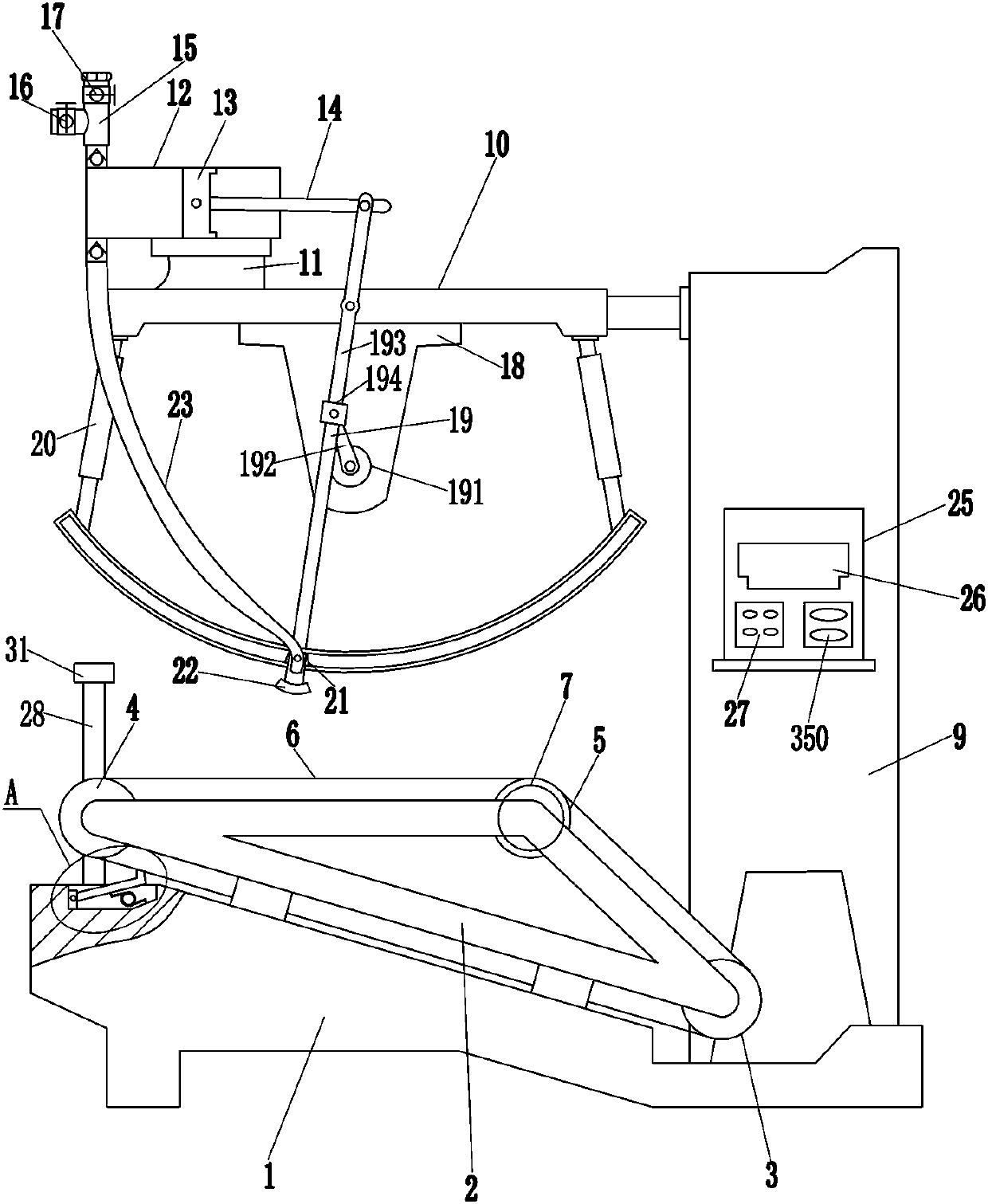

[0020] A pre-treatment equipment for freezing aquatic products, such as Figure 1-5 As shown, it includes a base 1, a mounting rod 2, a first transmission roller 3, a second transmission roller 4, a third transmission roller 5, a transmission belt 6, a first drive motor 7, a support frame 9, a support plate 10, and a support base 11 , Cylinder 12, Piston 13, Connecting Rod 14, Two Branches 15, First Solenoid Valve 16, Second Solenoid Valve 17, Mounting Seat 18, Pushing Device 19, Arc Frame 20, Arc Slider 21, Nozzle 22, Telescopic hose 23, control box 25, LCD display screen 26 and the first control panel 27, the front and rear sides of the top of the base 1 are fixedly connected with installation rods 2, and the right part between the two installation rods 2 is installed with the first transmission Roller 3, the second transmission roller 4 is installed on the left side between the two installation rods 2, the transmission belt 6 is wound between the first transmission roller 3...

Embodiment 2

[0022] A pre-treatment equipment for freezing aquatic products, such as Figure 1-5As shown, it includes a base 1, a mounting rod 2, a first transmission roller 3, a second transmission roller 4, a third transmission roller 5, a transmission belt 6, a first drive motor 7, a support frame 9, a support plate 10, and a support base 11 , Cylinder 12, Piston 13, Connecting Rod 14, Two Branches 15, First Solenoid Valve 16, Second Solenoid Valve 17, Mounting Seat 18, Pushing Device 19, Arc Frame 20, Arc Slider 21, Nozzle 22, Telescopic hose 23, control box 25, LCD display screen 26 and the first control panel 27, the front and rear sides of the top of the base 1 are fixedly connected with installation rods 2, and the right part between the two installation rods 2 is installed with the first transmission Roller 3, the second transmission roller 4 is installed on the left side between the two installation rods 2, the transmission belt 6 is wound between the first transmission roller 3 ...

Embodiment 3

[0025] A pre-treatment equipment for freezing aquatic products, such as Figure 1-5 As shown, it includes a base 1, a mounting rod 2, a first transmission roller 3, a second transmission roller 4, a third transmission roller 5, a transmission belt 6, a first drive motor 7, a support frame 9, a support plate 10, and a support base 11 , Cylinder 12, Piston 13, Connecting Rod 14, Two Branches 15, First Solenoid Valve 16, Second Solenoid Valve 17, Mounting Seat 18, Pushing Device 19, Arc Frame 20, Arc Slider 21, Nozzle 22, Telescopic hose 23, control box 25, LCD display screen 26 and the first control panel 27, the front and rear sides of the top of the base 1 are fixedly connected with installation rods 2, and the right part between the two installation rods 2 is installed with the first transmission Roller 3, the second transmission roller 4 is installed on the left side between the two installation rods 2, the transmission belt 6 is wound between the first transmission roller 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com