Corrugated steel plate rolling punching machine

A corrugated steel plate and punching machine technology, applied in the field of punching machines, can solve the problems of difficult control of hole position accuracy, difficult quality assurance, slow efficiency, etc., and achieve the effects of simple structure, reduced process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

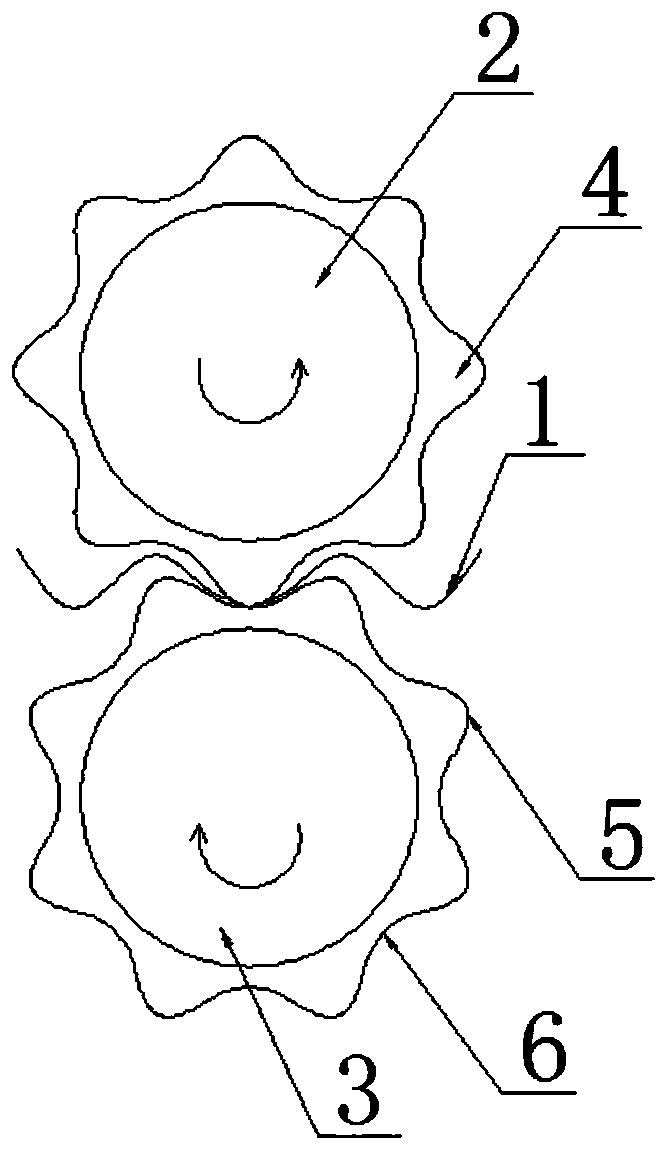

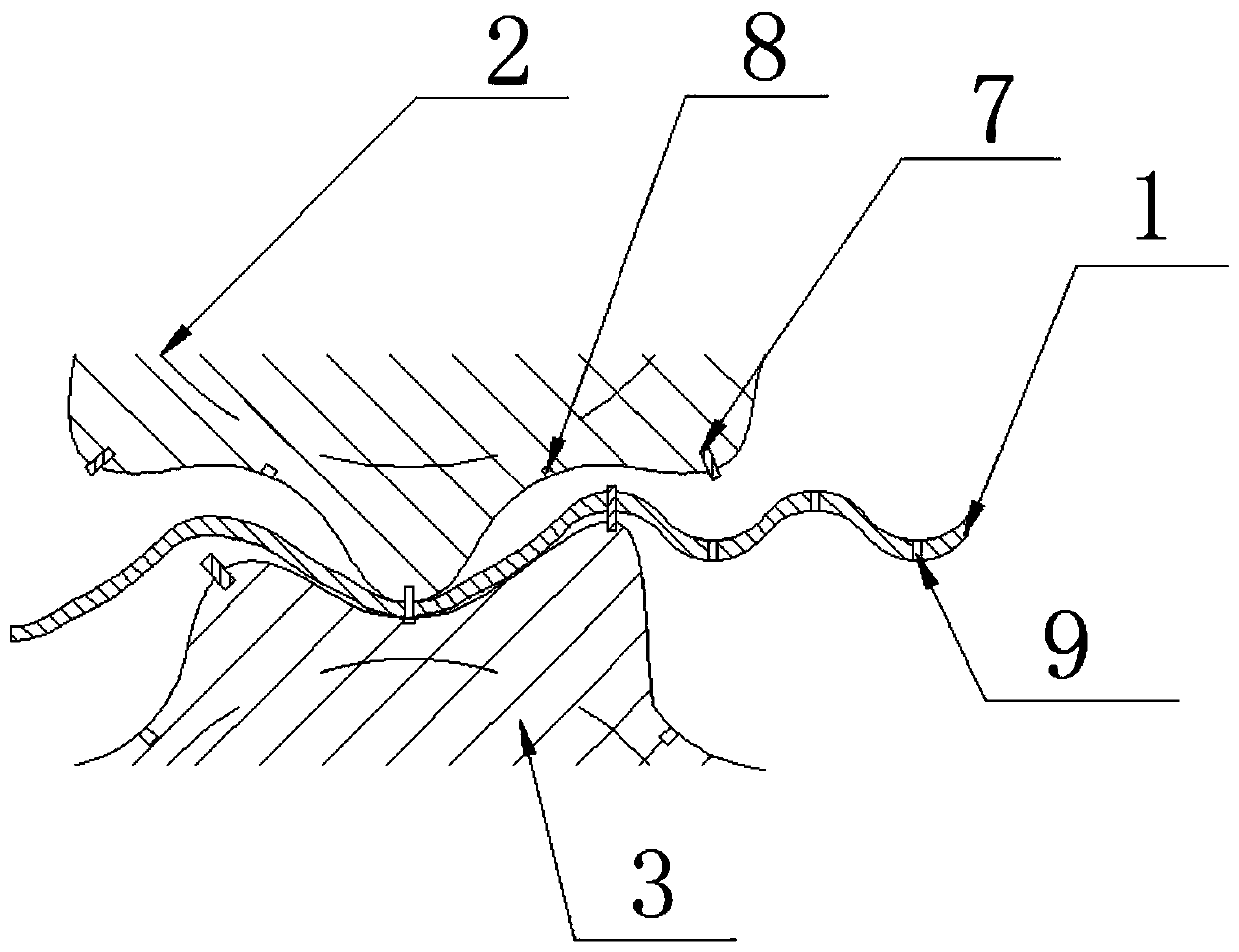

[0016] Such as figure 1 and figure 2 As shown, the present invention includes a corrugated steel plate 1, an upper roller shaft 2, a lower roller shaft 3, hobbing teeth 4, tooth crests 5, tooth valleys 6, punches 7, slots 8 and connection holes 9. Such as figure 1 As shown, two roller shafts, an upper roller shaft 2 and a lower roller shaft 3 , are arranged perpendicular to the advancing direction of the corrugated steel plate 1 . The two rollers are driven to rotate by a power mechanism such as a motor and a gear (not shown in the figure), and the directions of rotation are opposite. The upper roller 2 and the lower roller 3 are arranged up and down along the corrugated steel plate 1, and the axes of the two rollers Parallel, the plane formed by it is perpendicular to the plane of corrugated steel plate 1. The rotation directions of the two roller shafts are opposite,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap