Longitudinal climbing device for extra-large steel structure

A steel structure, super-large technology, applied in the direction of hoisting equipment braking device, hoisting device, bottom support structure, etc., can solve the problems of mutual interference of driving movement, mutual obstruction of two driving vehicles running in opposite directions, and neglect of equipment operating space, etc. To achieve the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

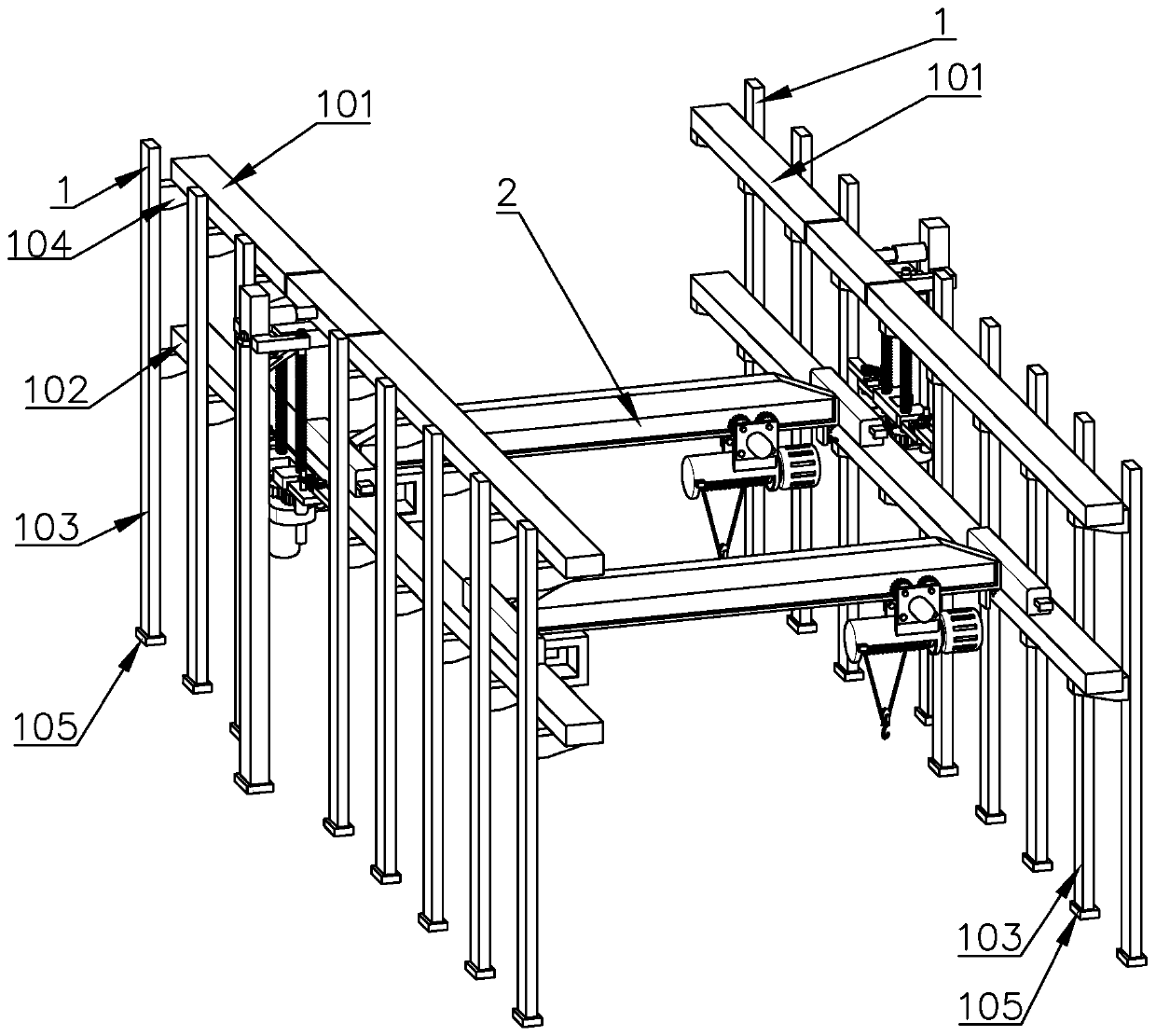

[0043] Embodiment 1: as Figure 1-7 shown;

[0044] An extra-large steel structure longitudinal climbing device, including a steel structure beam frame 1, a crane 2, a climbing mechanism 3, and a track adjustment mechanism 4; The beam frame 1 carries the crane 2 , the climbing mechanism 3 , and the track adjustment mechanism 4 , and the climbing mechanism 3 is connected to the track adjustment mechanism 4 through a column 103 .

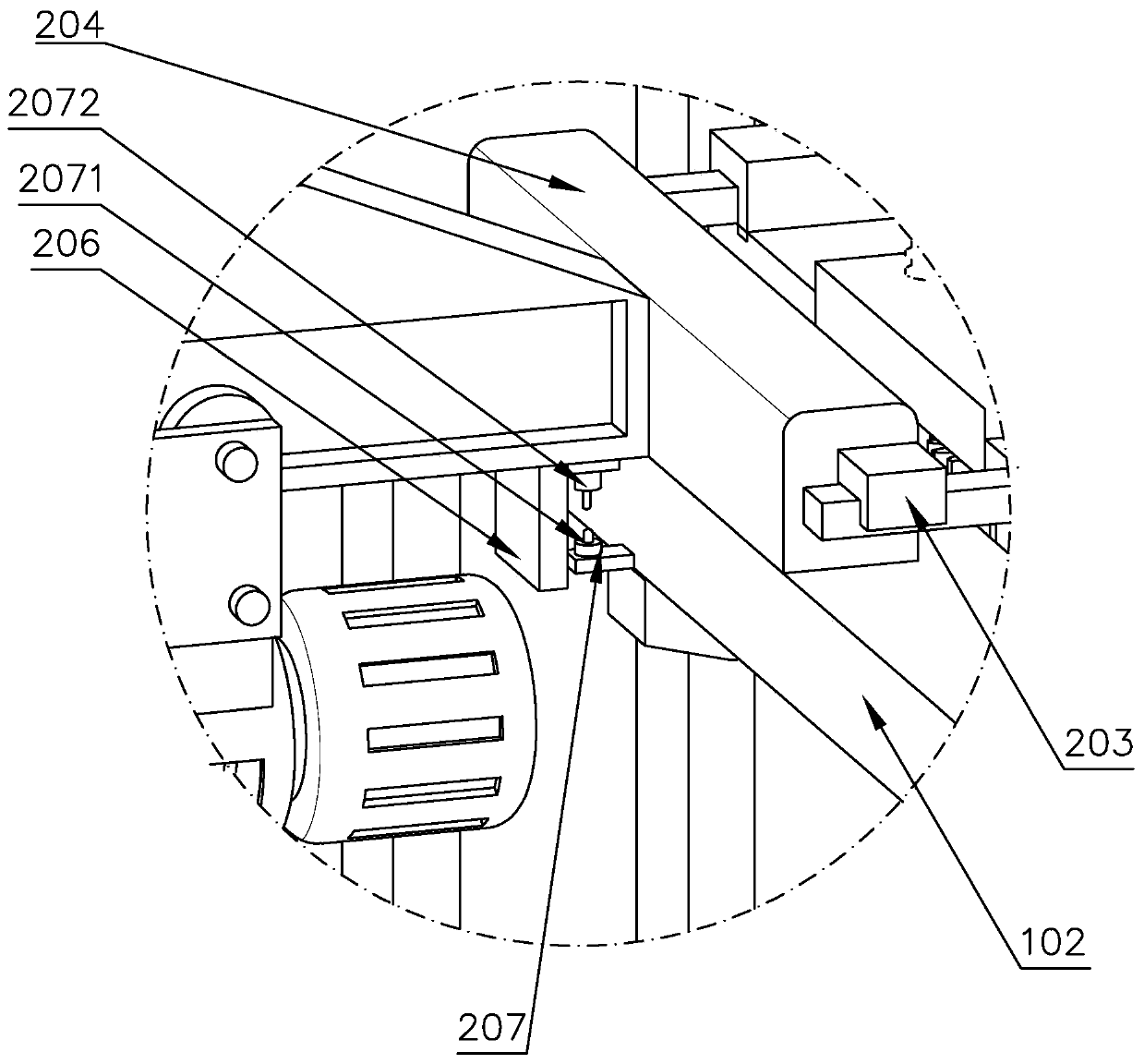

[0045] The steel structure beam frame 1 includes a driving track I101, a driving track II102, a column 103, a load-bearing fixing seat 104, and a fixing seat I105. The steel structure beam frame 1 is provided with a number of fixing seats I105. 103 is provided with a load-bearing fixed seat 104, and the loaded fixed seat 104 is provided with a driving track I 101 and a driving track II 102, and the driving vehicle 2 moves along the driving track I 101 or the driving track II 102.

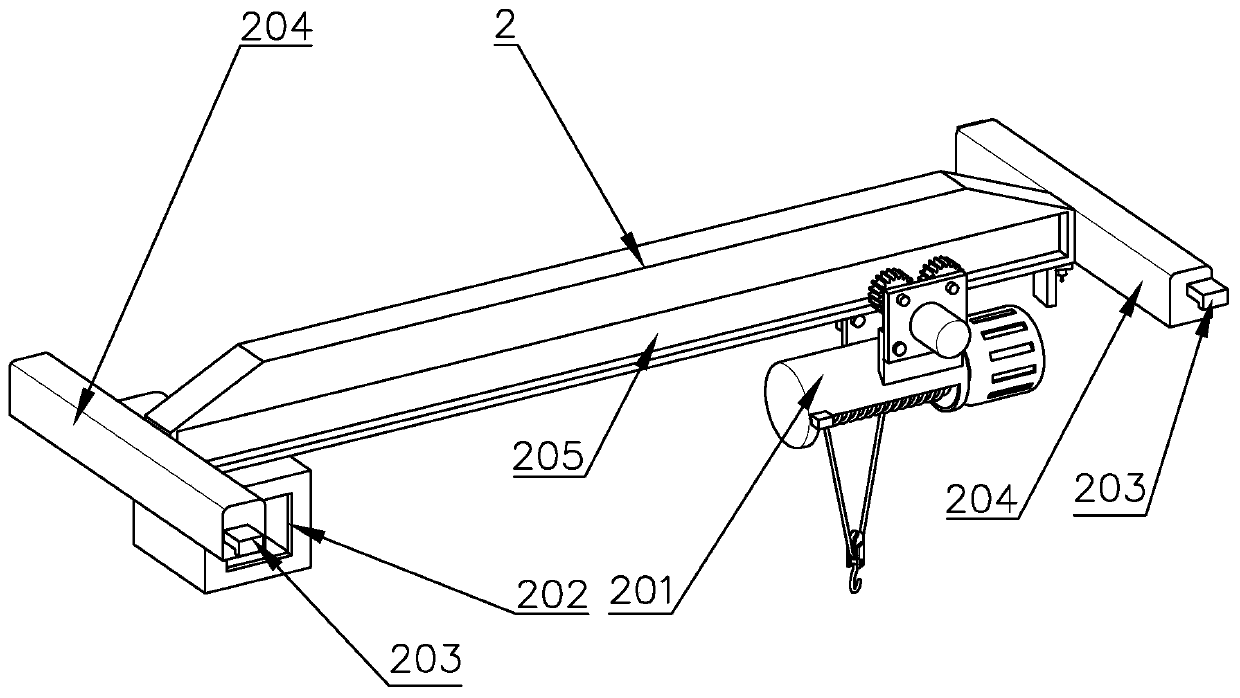

[0046] Described driving 2 comprises electric hoist 201, driver's ca...

Embodiment 2

[0053] Embodiment 2: as Figure 8-14 shown;

[0054] An extra-large steel structure longitudinal climbing device, including a steel structure beam frame 1, a crane 2, a climbing mechanism 3, and a track adjustment mechanism 4; The beam frame 1 carries the crane 2 , the climbing mechanism 3 , and the track adjustment mechanism 4 , and the climbing mechanism 3 is connected to the track adjustment mechanism 4 through a column 103 .

[0055]The steel structure beam frame 1 includes a driving track I101, a driving track II102, a column 103, a load-bearing fixing seat 104, and a fixing seat I105. The steel structure beam frame 1 is provided with a number of fixing seats I105. 103 is provided with a load-bearing fixed seat 104, and the loaded fixed seat 104 is provided with a driving track I 101 and a driving track II 102, and the driving vehicle 2 moves along the driving track I 101 or the driving track II 102.

[0056] Said crane 2 comprises electric hoist 201, driver's cab 202, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com