A local heat treatment device adapted to rapid repair in the field

A local heat treatment and rapid technology, applied in heat treatment furnaces, heat treatment equipment, fluid heaters, etc., can solve the problems of inconvenient movement, difficult to adjust the temperature in real time, difficult to transfer, etc., and achieve the effect of efficient, uniform, efficient and convenient heat treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

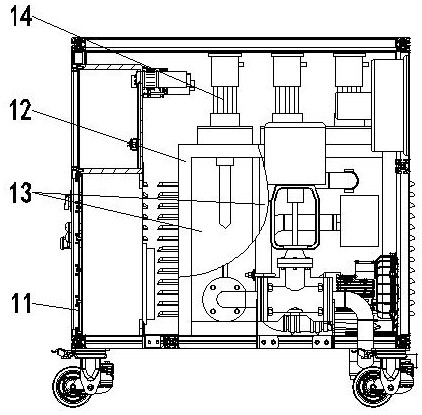

[0042] In this embodiment, a local heat treatment device adapted to rapid repair in the external field, such as figure 1 As shown, the air heater assembly 1 is included, and the air heater assembly 1 includes a box body 111 with an air inlet and an air outlet. The inside of the box body 111 is provided with an explosion-proof heating air bag 12, and the heating air bag The air inlet end of 12 is connected with the air inlet of box body 11 through fan, and the air outlet end of heating air bag 12 is connected with the air outlet of box body; The inside of described explosion-proof heating air bag 12 is divided into several sections and communicates with each other in turn along the direction of air flow. Each heating package section 13 is matched with an explosion-proof heater 14 for heating the air inside the heating package section 13 .

[0043] Both ends of the bottom of the box body 111 are respectively provided with fixed casters and swivel casters, and the convenient and ...

Embodiment 2

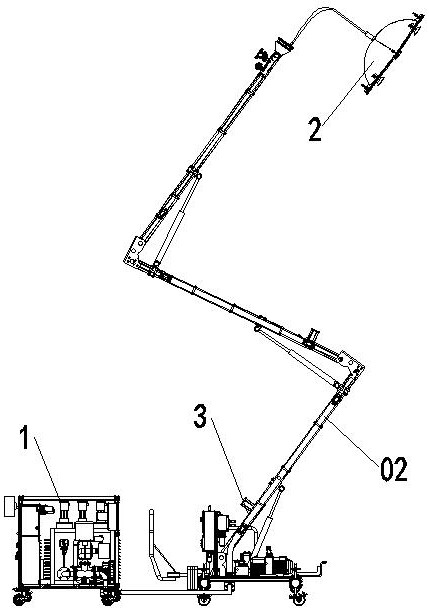

[0046] This embodiment is further optimized on the basis of embodiment 1, such as figure 2 As shown, it also includes a windshield assembly 2 and a pipe lifting assembly 3, the air inlet end of the windshield assembly 2 communicates with the air outlet of the box body 11 through the ventilation duct 02, and the air outlet end of the windshield assembly 2 is connected to the The heat treatment surface is bonded; the pipe lifting assembly 3 is arranged between the air heater assembly 1 and the wind shield assembly 2 and is used to lift the ventilation pipe 02 .

[0047] The wind cover assembly 2 is a cover structure with an air inlet end and an air outlet end. The air outlet end of the wind cover assembly 2 is bonded to the heat treatment surface to form a relatively airtight heating area. The air inlet end of the wind cover assembly 2 passes through the ventilation duct 02 is connected to the air outlet of the box body 111, the ventilation duct 02 is a retractable duct, and th...

Embodiment 3

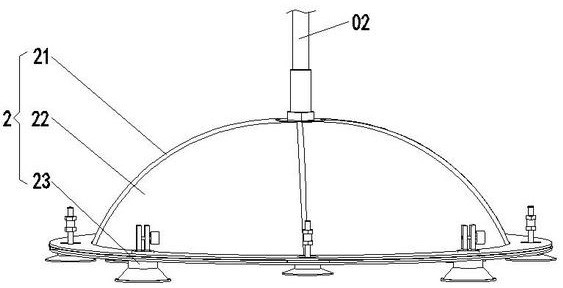

[0052] This embodiment is further optimized on the basis of above-mentioned embodiment 1 or 2, such as figure 2 and image 3 As shown, the windshield assembly 2 includes a carbon fiber skeleton 21, an insulating material layer 22, and a combined suction cup 23. The carbon fiber skeleton 21 and the insulating material layer 22 form a cover structure, and the end of the cover structure away from the heat treatment surface passes through The joint is connected to the air outlet end of the ventilation duct 02, and the end of the cover structure close to the heat treatment surface is evenly provided along the edge with several combined suction cups 23 for absorbing close to the heat treatment surface.

[0053] The carbon fiber skeleton 21 is arranged in an umbrella shape or a square frame shape, and the carbon fiber skeleton 21 is arranged in an umbrella shape, which can be conveniently folded and unfolded. When the windshield assembly 2 is not in use, the carbon fiber frame 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com