RAP fine material drying and heating equipment

A technology of drying, heating and fine materials, which is applied in roads, road repairs, roads, etc., can solve the problems of asphalt loss of function, adhesion, and high heating efficiency, so as to increase the heating and evaporation area, solve the adhesion problem, and improve heating efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

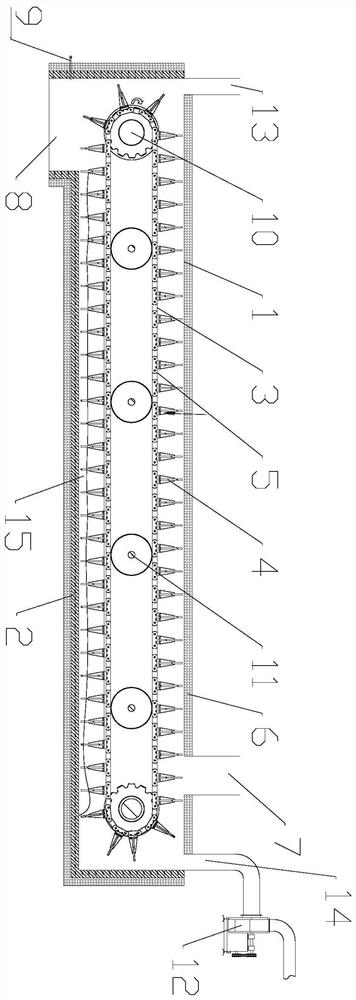

[0046] Please refer to figure 1 , a RAP fine material drying and heating device, comprising a housing 1, a conveying assembly and a heating layer 2;

[0047] Both the transmission component and the heating layer 2 are arranged in the casing 1, and the heating layer 2 is arranged at the bottom of the casing 1;

[0048] The conveying assembly includes a conveying chain 3 and several scraper blades 4 arranged on the conveying chain 3;

[0049] There is a gap between the scraper blade 4 and the heating layer 2 .

[0050] Specifically, the conveying chain 3 is composed of several driving chains 5, and above the heating layer 2 is a RAP fine material layer.

[0051] The outer surface of the housing 1 is provided with an insulating layer 6 .

[0052] The housing 1 is provided with a material inlet 7 and a material outlet 8 .

[0053] Also includes a thermometer 9;

[0054] The temperature measuring instrument 9 is fixedly connected with the casing 1 , and one end of the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com