A Concrete Reinforcing Method for Sealed Joints of Pipelines

A technology for concrete reinforcement and pipe sealing, which is used in sewer systems, waterway systems, buildings, etc., can solve problems such as water leakage in pipes, easily damaged welded structures at pipe sealing joints, etc., so as to reduce structural damage, improve installation quality, and ensure strength. and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Such as Figure 1 to Figure 10 Shown, be a kind of concrete reinforcement method that is used for pipeline sealing joint of the present invention, comprises the steps:

[0054] a, the installation of the first pipeline 12:

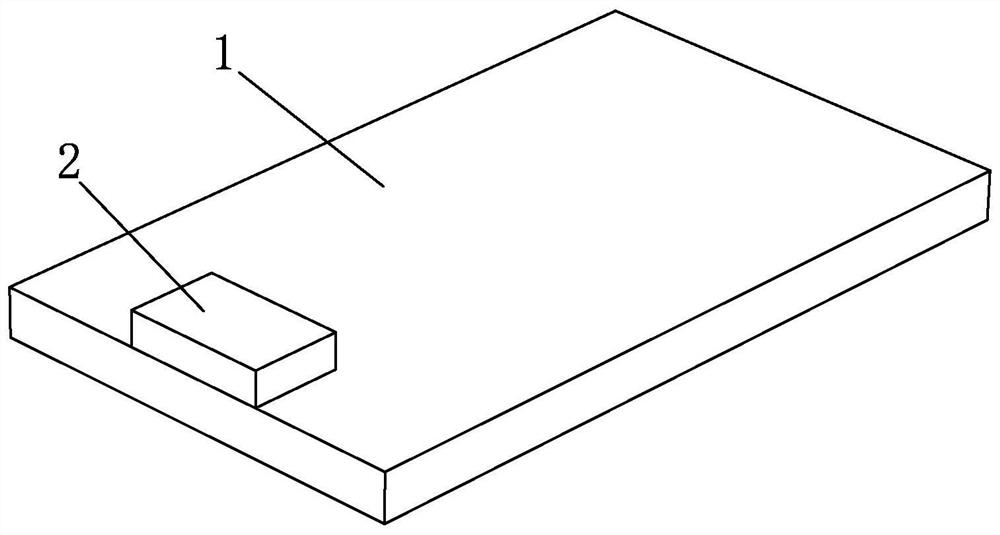

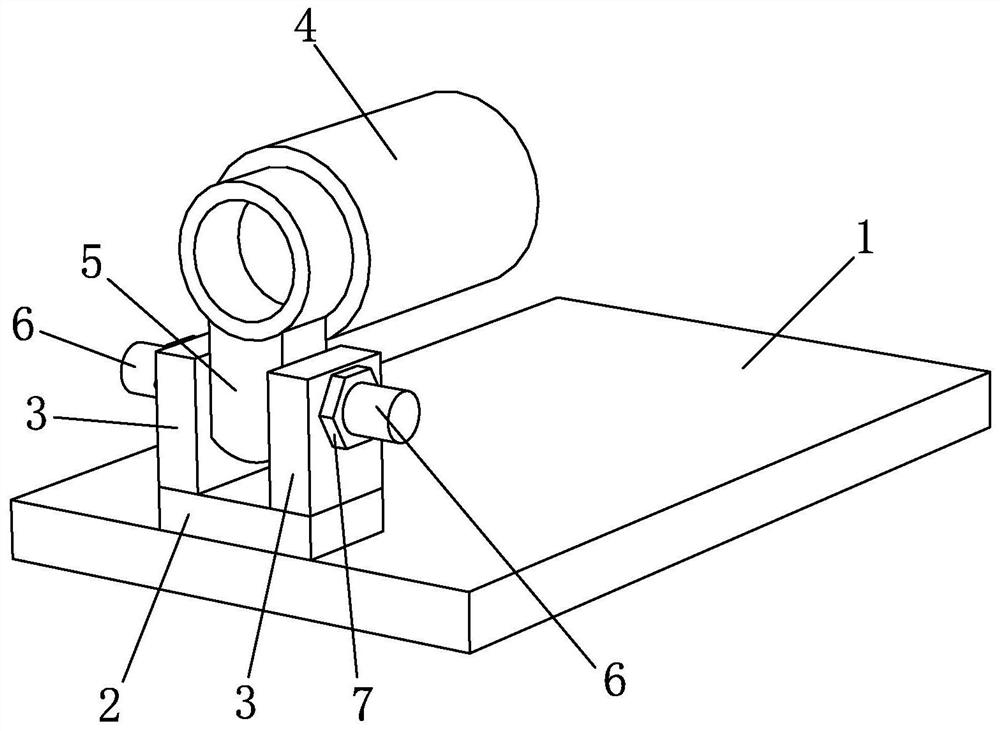

[0055] 1) Lay the installation steel plate 1 horizontally on the foundation, measure the installation steel plate 1, draw the first pipeline installation position, and then weld the backing plate 2 at the drawn first pipeline installation position.

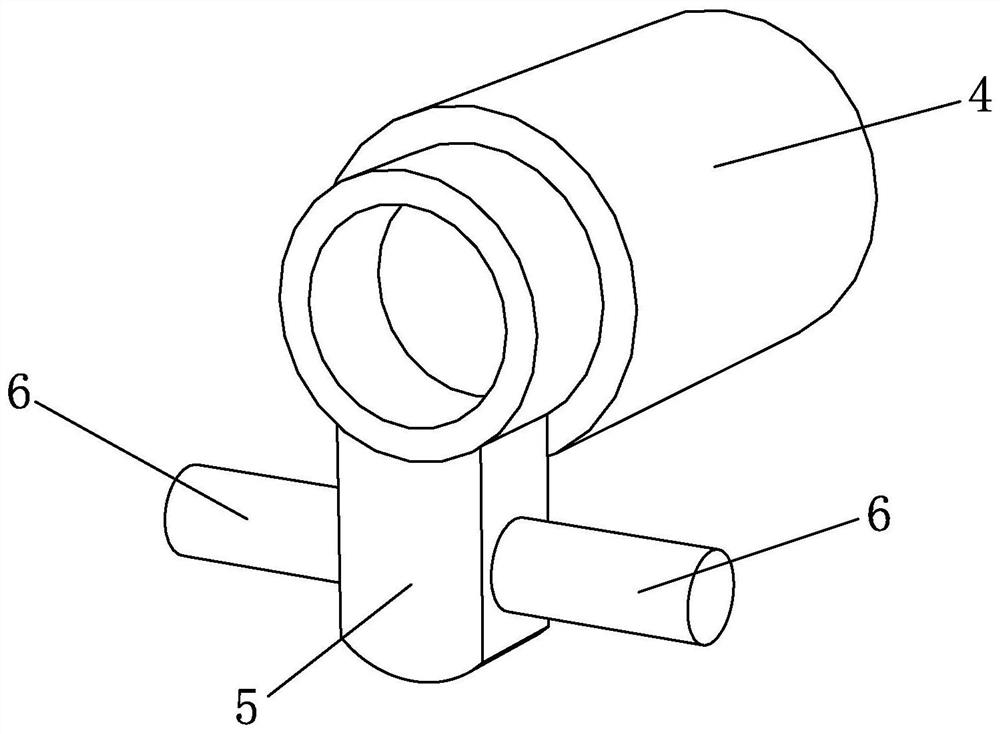

[0056] 2) The first connection sleeve 4 is prepared, the bottom of the first connection sleeve 4 is provided with a deflection rod 5 , and the two sides of the deflection rod 5 are provided with a rotation rod 6 .

[0057] 3) Weld a side plate 3 on the backing plate 2, then insert the rotating rod 6 into the side plate 3, then insert another side plate 3 onto the other rotating rod 6, and then weld the side plate 3 on backing plate 2. Keep the first connecting sleeve 4 in a horizontal state again, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com