Machine tool cutter residual life prediction method based on LSTM + CNN

A life prediction and tool technology, applied in prediction, neural learning method, measuring device and other directions, can solve the problems of tool wear, cost increase, tool waste, etc., to achieve the effect of fitting prevention, improving accuracy and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

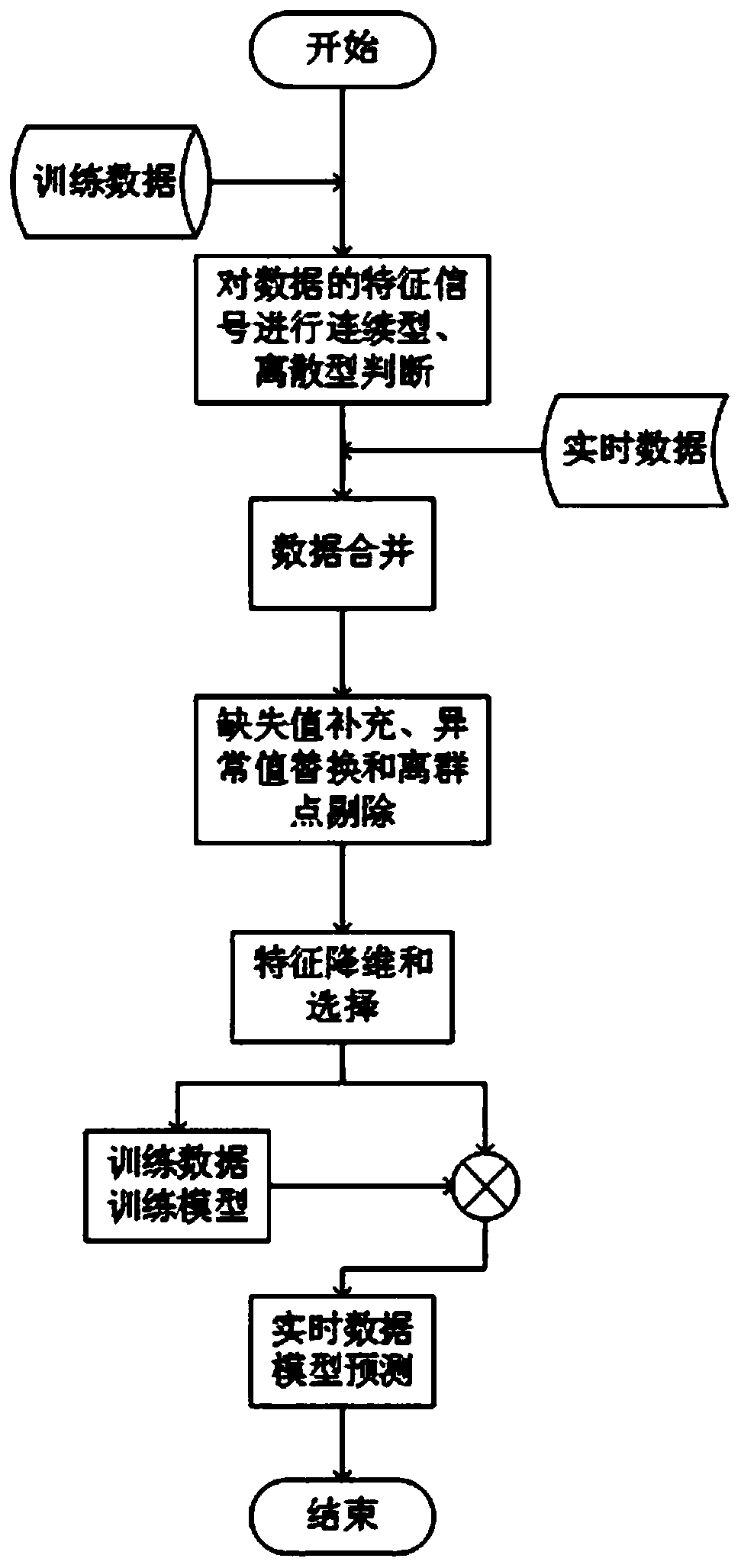

[0047] Such as figure 1 As shown, the tool usage (historical data) of a milling machine is used to predict the remaining life of the tool according to the uploaded sensor signal and PLC signal;

[0048] If the frequency of the sensor signal and the PLC signal are different (generally different), the data needs to be merged;

[0049] There are many abnormal data in real data, and the data needs to be cleaned;

[0050] Then train LSTM first, then train CNN, judge whether the model is good or bad (error size), adjust parameters and then train to get a satisfactory model;

[0051] Then, according to the real-time data of the milling machine tool, the same steps of data cleaning are performed, and the model is input for prediction, and the tool is replaced according to the real-time prediction result.

Embodiment 2

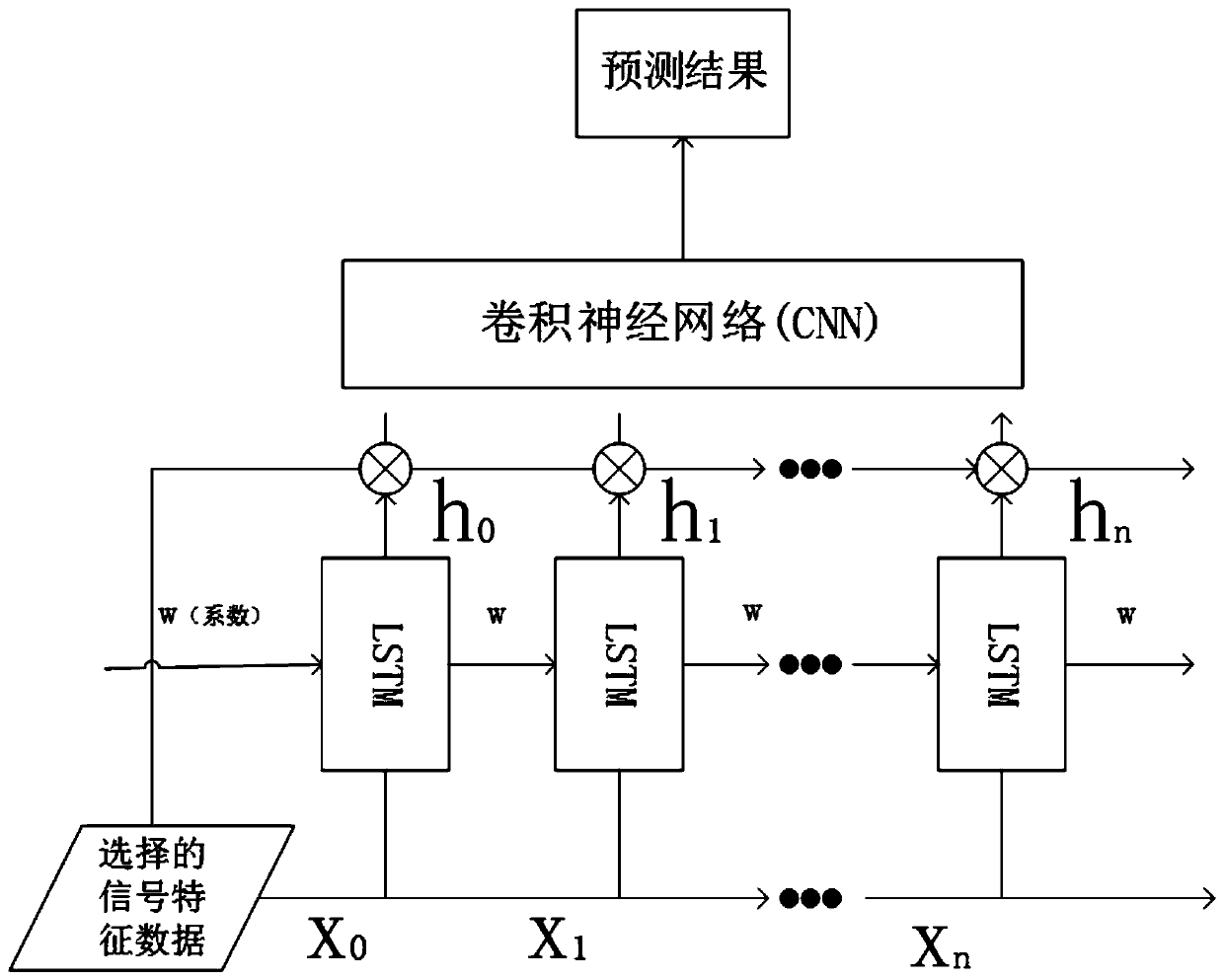

[0053] Such as figure 2 As shown, between the X and h sequences in the figure is the simplified schematic part of the LSTM model. The LSTM+CNN model and the training and prediction process are as follows:

[0054] Using the training data, assign the data according to the cross-validation principle, and perform supervised learning on the LSTM;

[0055] Use the result data predicted by LSTM as a one-dimensional data variable, and the variables in the training LSTM data after feature selection and dimensionality reduction, such as feature selection for displacement in X, Y, and Z directions, and vibration signals in X, Y, and Z axes , select several variables that are most relevant to the remaining life of the tool, and the feature selection method is the Pearson correlation coefficient algorithm combined as the input of CNN to train it.

[0056] In the process of supervised learning, the accuracy of LSTM is higher by adjusting the LSTM network and training parameters.

[0057...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com