Optimized operation method of vacuum pump set of thermal power plant

A thermal power plant, optimized operation technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of few cleaning coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

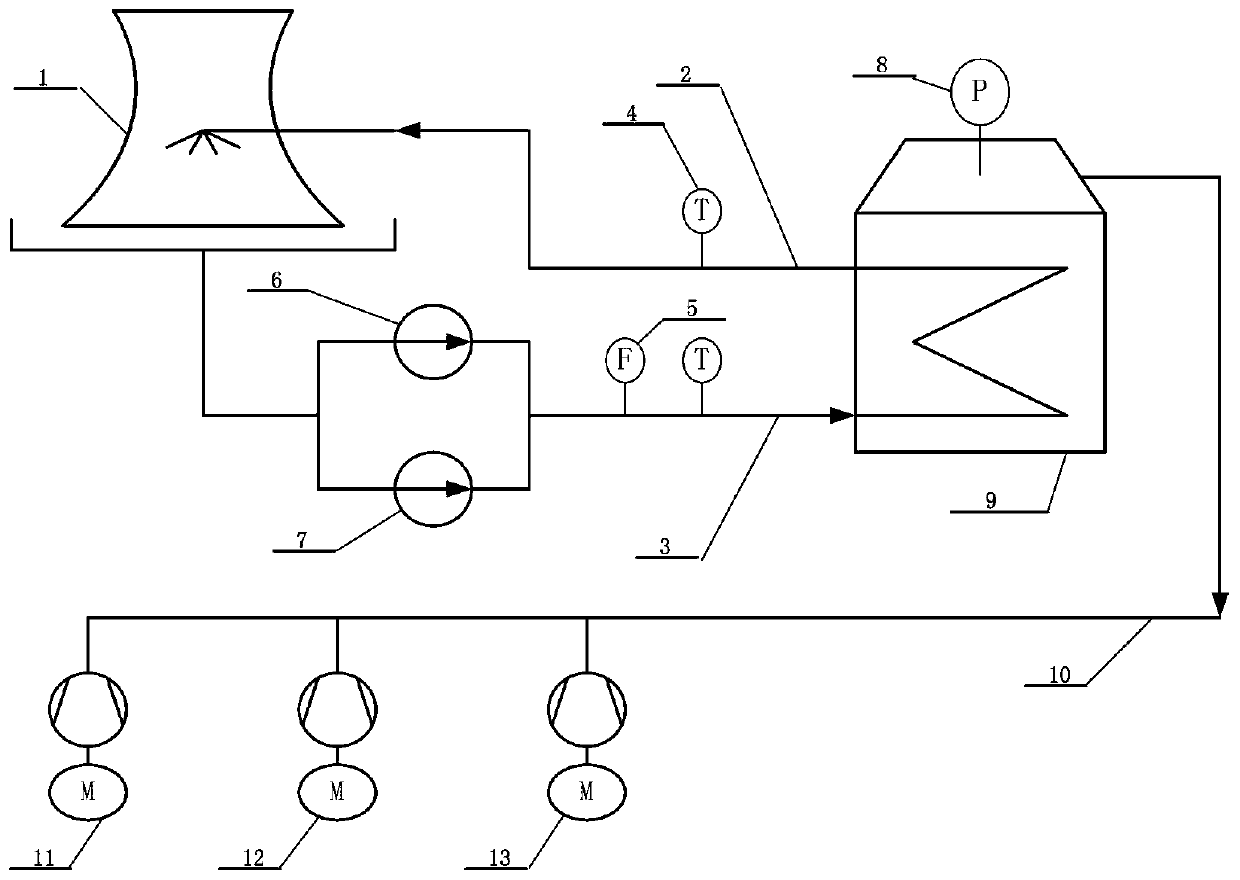

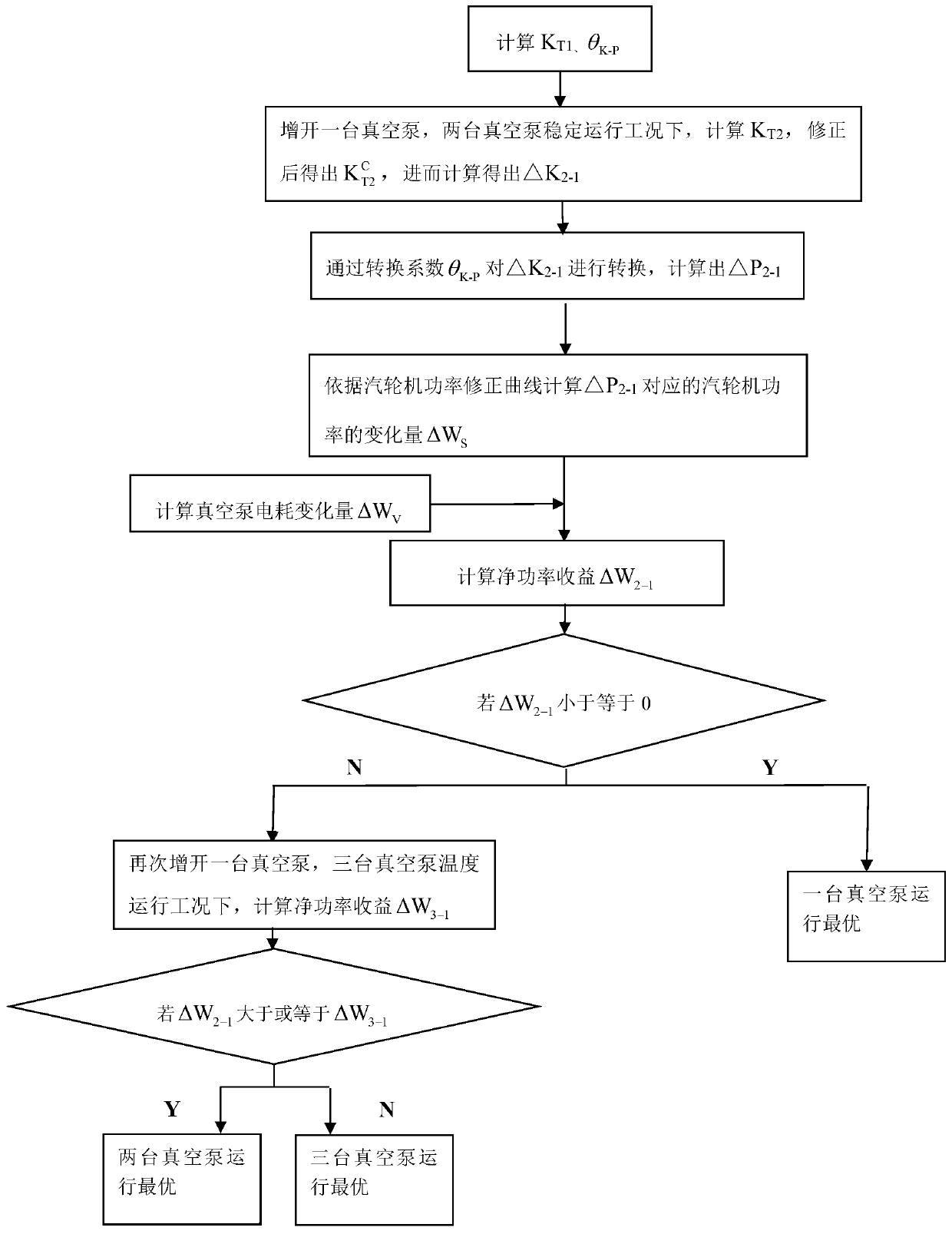

[0052] This embodiment adopts the method for optimizing the operation of a vacuum pump set in a thermal power plant of the present invention to optimize the operation of a vacuum pump set. The monitoring system used in this method includes a condenser 9, a vacuum pump set, a circulating water pump, a cooling tower, and a condenser. The suction of 9 is connected to the vacuum pump group through the suction pipe; the water inlet of the condenser 9 water chamber is connected to the circulating water pump through the circulating cooling water inlet pipe 3. The other side of the circulating water pump is connected to the tower pool at the bottom of the cooling tower, and the water outlet of the water chamber is connected through The circulating cooling water return pipe 2 is connected to the cooling tower 1. The vacuum pump set in this embodiment includes three vacuum pumps, namely vacuum pump A11, vacuum pump B12, and vacuum pump C13; the three vacuum pumps are all selected as water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com