Sugar cube forming machine and its application

A forming machine and forming mechanism technology, applied in the fields of application, confectionery, confectionary industry, etc., can solve the problems of inconvenient cleaning of the main drum, achieve the effects of increasing the speed, ensuring the demoulding rate, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

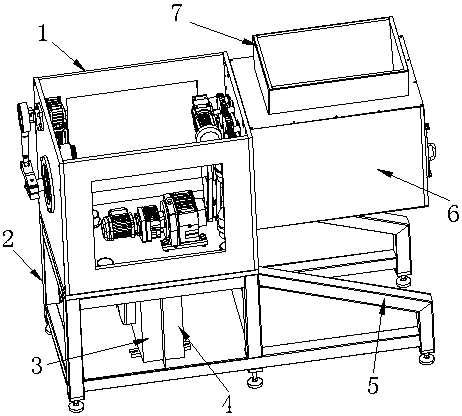

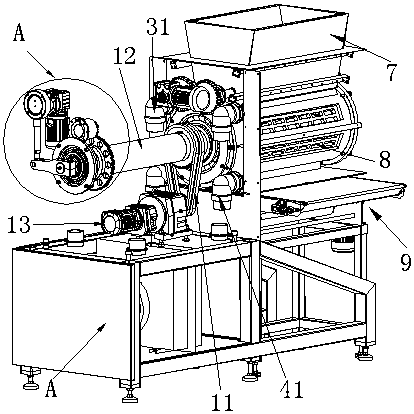

[0033] With reference to the accompanying drawings, this candy block forming machine is used to accept viscous sugar material, shape and solidify the sugar material into a sugar block, and then make the finished sugar block and be transported to the outside by the belt conveyor 9.

[0034] See figure 1 , the candy forming machine is supported by a frame, and the structure of the frame includes three boxes, namely the forming box 6, the driving box 1 and the supporting box 2, and the driving box 1 is arranged on the supporting box 2 Above, the forming box body 6 and the driving box body 1 are horizontally arranged side by side. This arrangement makes a space be formed at the frame position, the space is positioned at the lower side of the forming box 6 and the outside of the supporting box 2, the space is used to arrange the conveying device 9, and the sugar cubes fall from the forming box 6. Fall on the conveying device 9, and be conveyed to the outside of candy bar forming m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com