Flue gas denitrator of coal-fired boiler

A technology for coal-fired boilers and flue gas, which is used in gas treatment, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of no water storage parts, easy water seepage, low denitration efficiency, etc., and achieves increased purification range, The effect of improving speed and preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

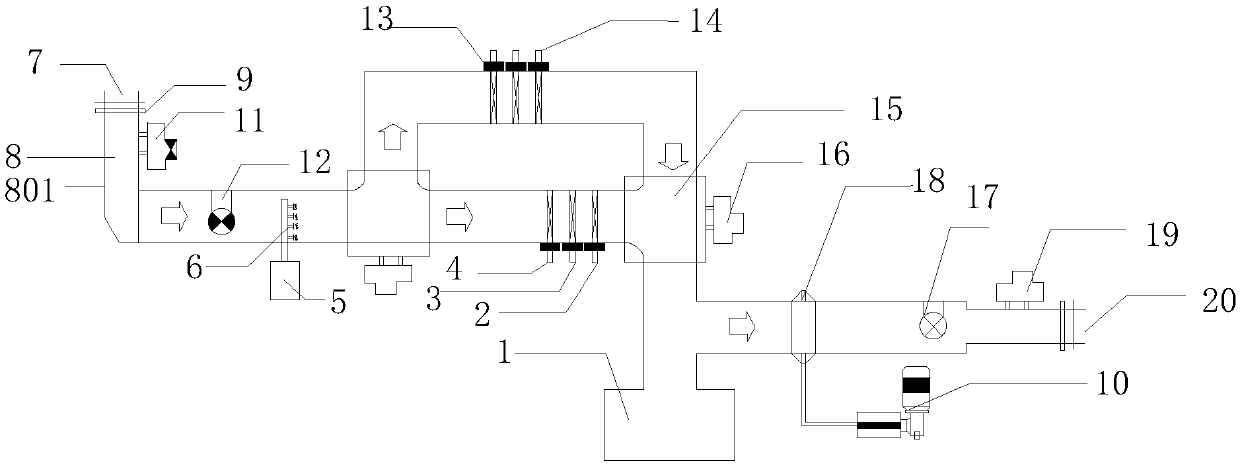

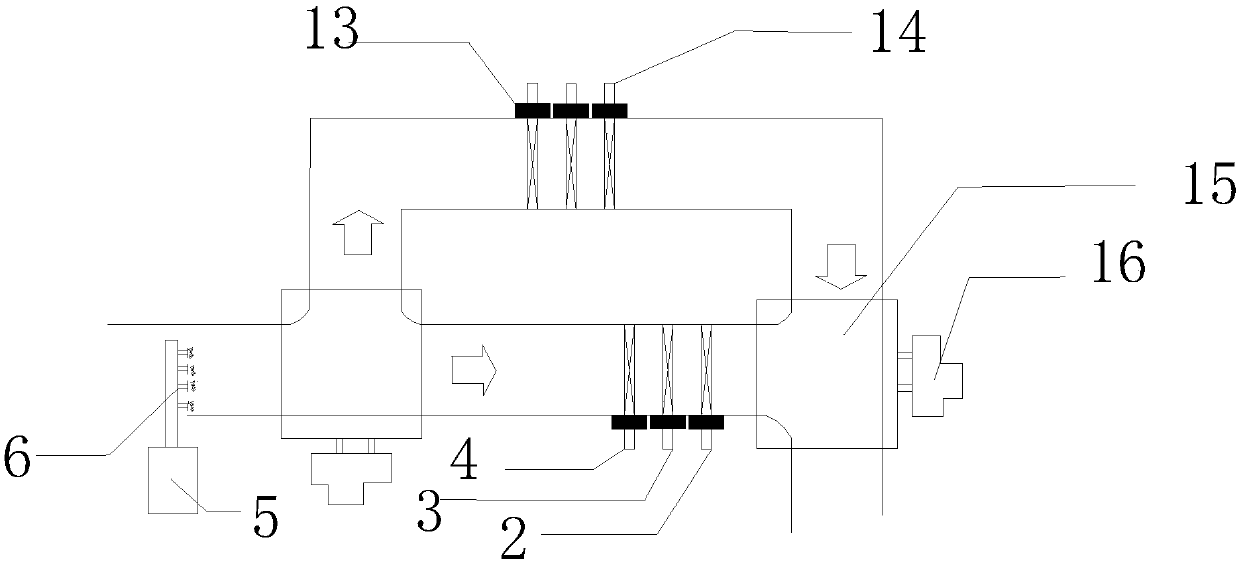

[0015] A coal-fired boiler flue gas denitrifier, characterized in that its structure includes a water storage tank 1, a first plate-type catalytic layer 2, a second plate-type catalytic layer 3, a third plate-type catalytic layer 4, an ammonia storage tank 5, an ammonia Air injector 6, air inlet 7, cylinder 8, anti-corrosion heat insulation layer 801, expansion joint 9, small motor 10, air inlet valve 11, first smoke detector 12, sealing ring 13, stainless steel grid 14, three Through converter 15, three-way valve 16, second smoke detector 17, dust collector 18, air outlet valve 19, air outlet 20; the expansion joint 9 is connected to the air inlet 7, and the air inlet valve 11 is fixed At the air inlet 7, the first flue gas detector 12 is connected with the cylinder body 8 and fixed at the air inlet 7, the ammonia storage tank 5 is connected with the ammonia injector 6, and the three-way conversion The device 15 is connected with the three-way valve 16, the sealing ring 13 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com