Waste paper product automatic screening and processing assembly line and processing method

A technology for automatic screening and paper products, applied to chemical instruments and methods, filters, grids, etc., can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

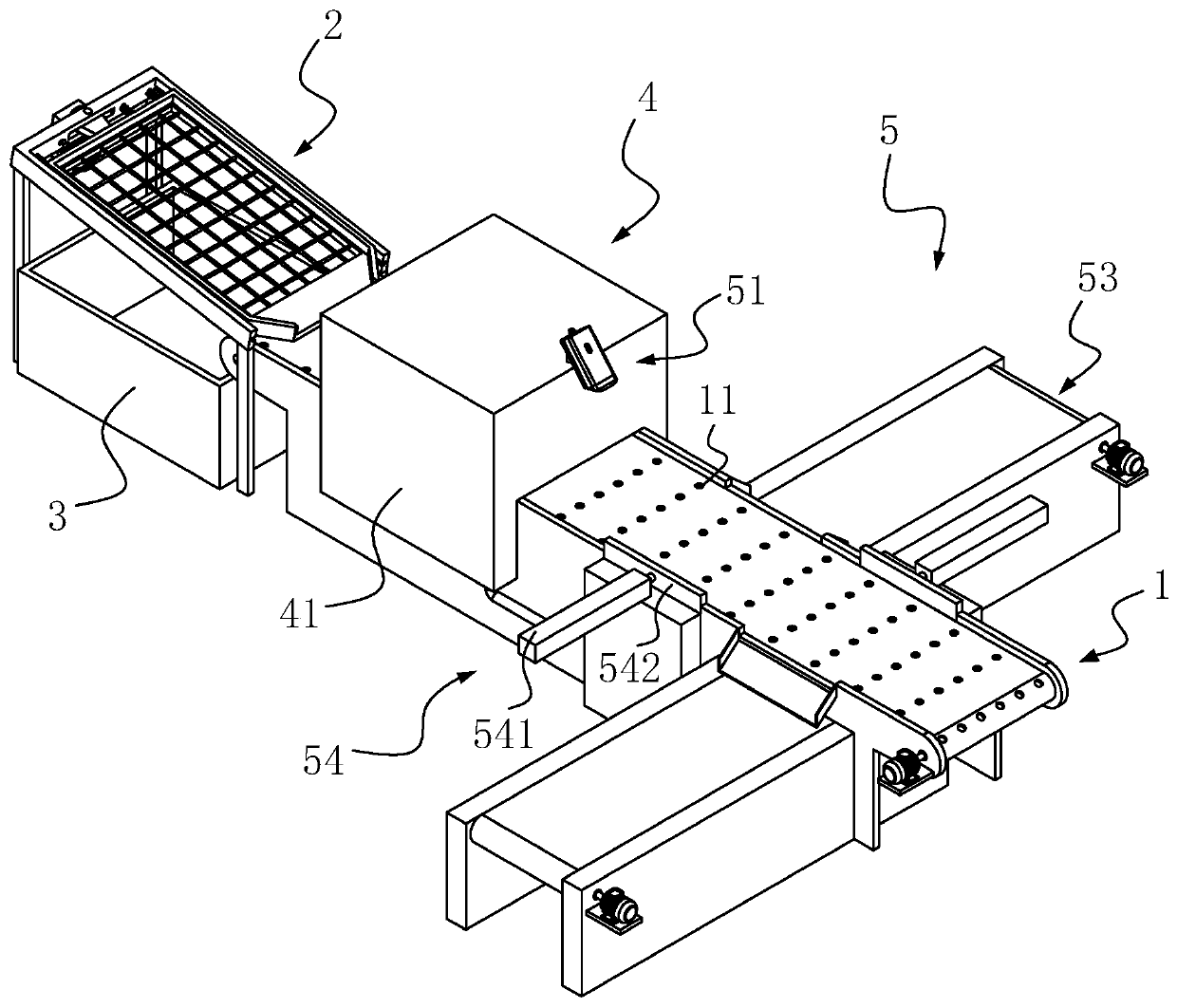

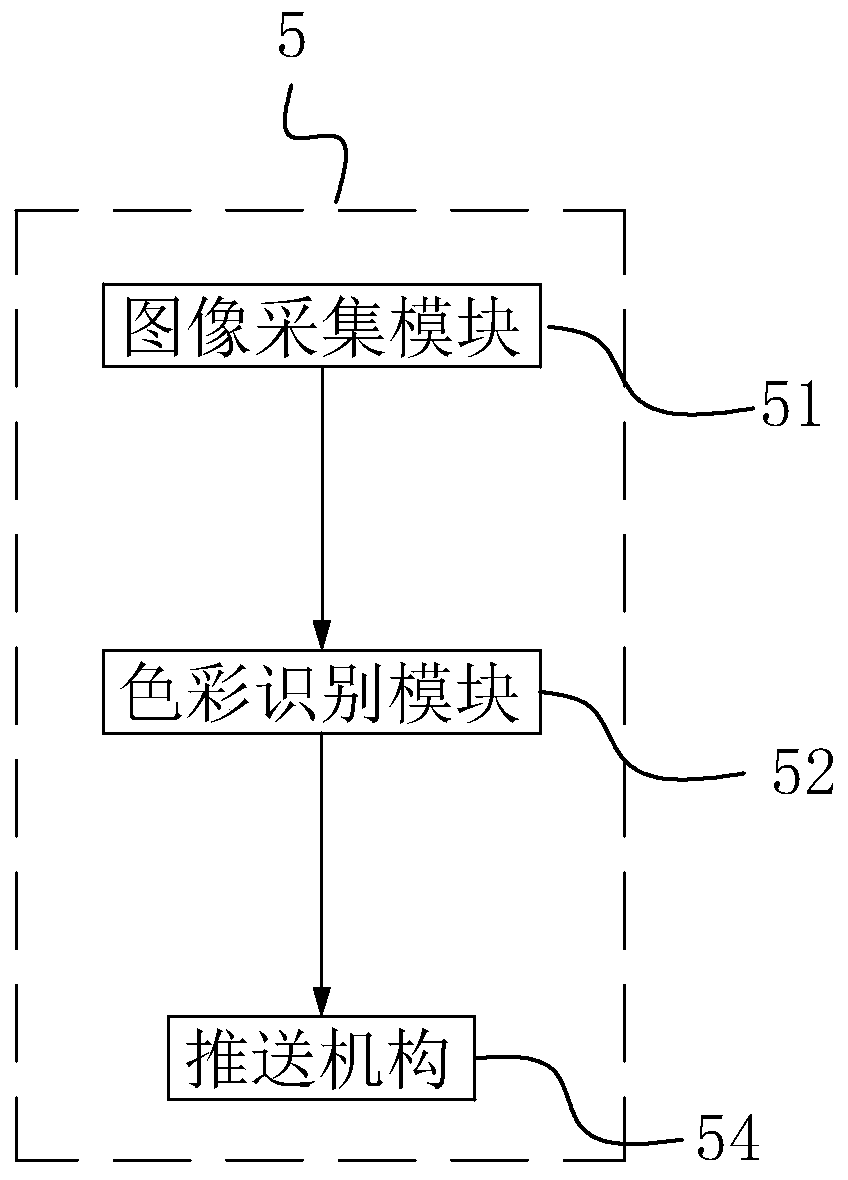

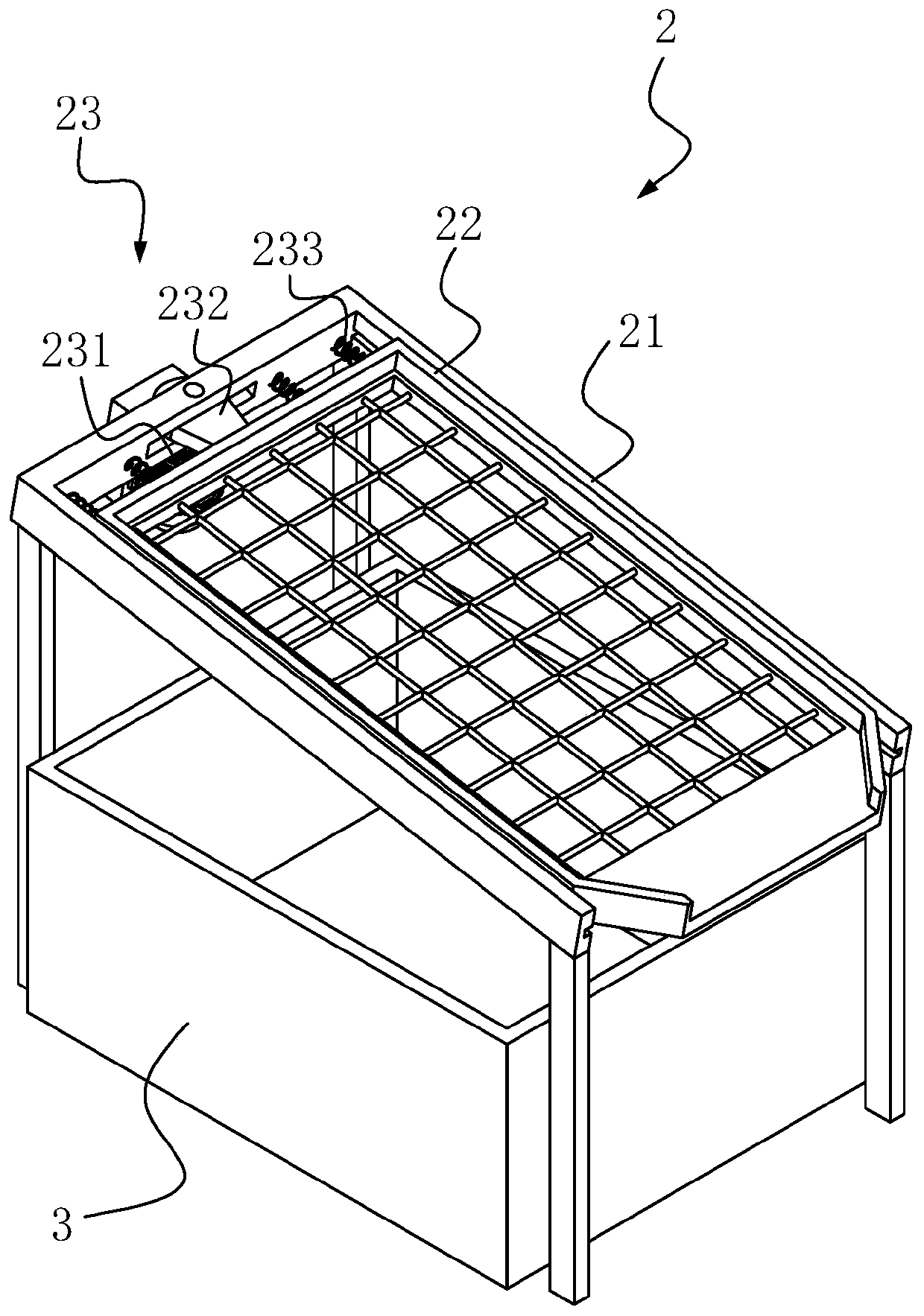

[0038] Example 1: An automatic screening and processing line for waste paper products, refer to figure 1 with figure 2, including the main transmission line 1, the feeding end of the main transmission line 1 is provided with a vibrating screen 2 inclined downward from the side away from the main transmission line 1 to the side of the main transmission line 1, and the bottom of the vibrating screen 2 is provided with a receiving basket 3. The main transmission line 1 is sequentially provided with a drying device 4 and a color screening device 5 from the feed end to the discharge end. The color screening device 5 includes an image acquisition module 51, a color recognition module 52, and several sub-transmission lines 53 perpendicular to the transmission direction of the main transmission line 1. Pushing mechanism 54 on 53; Image collection module 51 collects the image of the paper product through image collection module 51, and the image information of collection is sent to c...

Embodiment 2

[0043] A method for automatic screening and processing of waste paper products, characterized in that it comprises the following method steps:

[0044] Step S1: Screening of shredded paper, sieving the products through the inclined vibrating screen 2, so that the shredded paper falls through the vibrating screen 2, and the paper products slide along the vibrating screen 2 to the conveying equipment.

[0045] Step S2: Drying of paper products. During the transmission of the transmission equipment, make the paper products pass through the drying chamber 41, and dry the paper products through the hot air flow; use the main transmission line 1 to transport the paper products. The surface of the conveyor belt is provided with air holes 11 penetrating through the conveyor belt, and an airflow source is provided under the conveyor belt at the same time.

[0046] Step S3: Color recognition and screening, judge the color of the paper product through image acquisition and color recognit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com