Method for controlling temperature of strip steel tail part in U-type cooling

A temperature control and tail control technology, applied in the direction of temperature control, etc., can solve the problems of large difference from the actual value, incomplete and regular slab shape, and long distance to raise the target temperature of the tail, so as to avoid cross-interference problems and reduce production. The effect of reducing scrap rate and improving process compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Example 1: The actual strip length is much smaller than the first calculated value

[0099] Slab length 10.84m

[0100] Slab width 1070mm

[0101] Slab thickness 230mm

[0102] Target finished product width 900mm

[0103] Target finished product thickness 3.52mm

[0104] Cooling process: U type

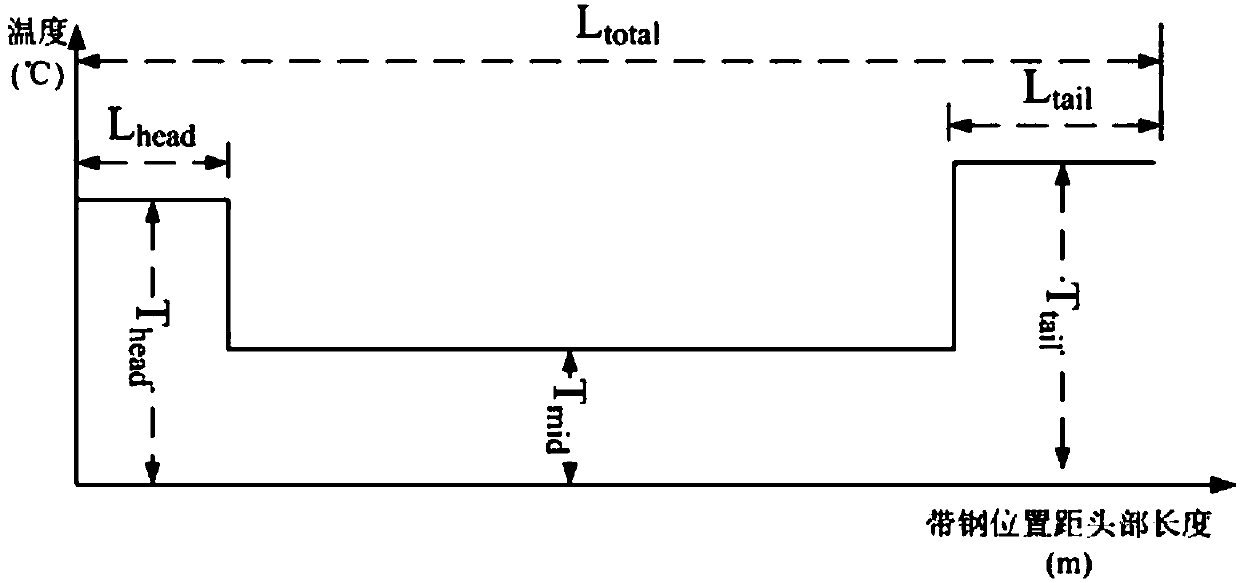

[0105] Head length 80 meters, target temperature 720°C

[0106] Intermediate target temperature 680°C

[0107] Tail length 80 meters, target temperature 730°C

[0108] Segment length 5.6m

[0109] Production time: 2018 / 03 / 19 05:31:08

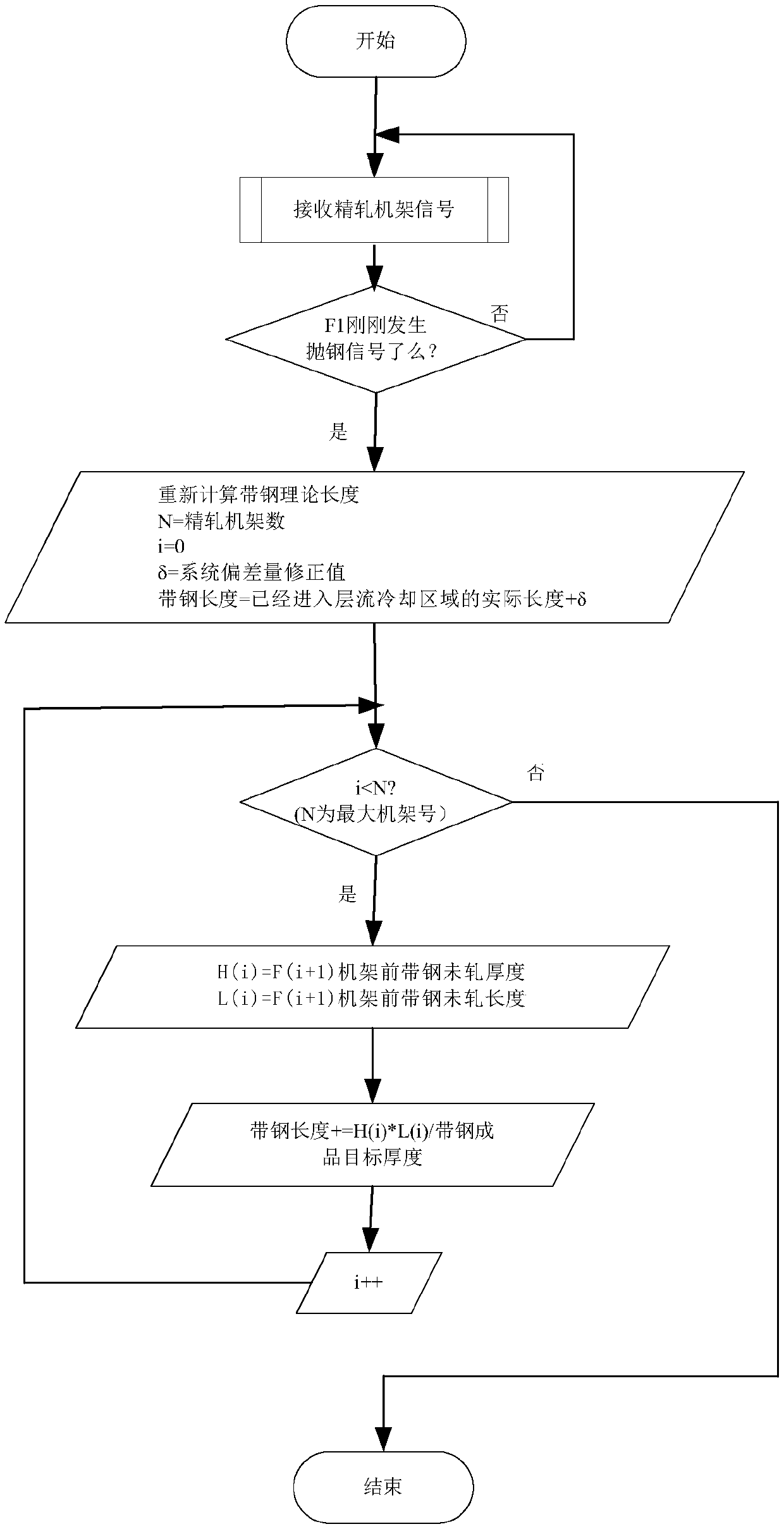

[0110] according to The initial theoretical length of the strip can be calculated as:

[0111] Ltotal initial=230*10.84*1070 / (900*3.52)=842m

[0112] And according to The resulting strip length is:

[0113] Ltotal recalc = 802m

[0114] The value of the genetic coefficient at a certain position x of the strip steel is:

[0115]

[0116] The actual length of the strip after coiling is 800m, and its actual temperature curve is a...

Embodiment 2

[0119] Example 2: The actual strip length is much greater than the first calculated value

[0120] Slab length 8.4m

[0121] Slab width 1342mm

[0122] Slab thickness 230mm

[0123] Target finished product width 1270mm

[0124] Target finished product thickness 3.23mm

[0125] Cooling process: U type

[0126] Head length 80 meters, target temperature 740°C

[0127] Intermediate target temperature 700°C

[0128] Tail length 80 meters, target temperature 750°C

[0129] Segment length 5.6m

[0130] Production time: 2018 / 03 / 18 11:11:33

[0131] according to The initial theoretical length of the strip can be calculated as:

[0132] Ltotal initial=230*8.4*1342 / (1270*3.23)=632m

[0133] And according to The resulting strip length is:

[0134] Ltotal recalc = 682m

[0135] The value of the genetic coefficient at a certain position x of the strip steel is:

[0136]

[0137] The actual length of the strip after coiling is 675m, and its actual temperature curve is as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com