High-efficiency closing compactor at the filter bowl filter screen end of automobile engine oil collector

A technology of oil filter and automobile engine, which is applied to engine components, mechanical equipment, etc., can solve the problems of high scrap rate, high labor intensity, low production efficiency, etc., and achieve the reduction of production scrap rate, high degree of automation, and improvement of production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

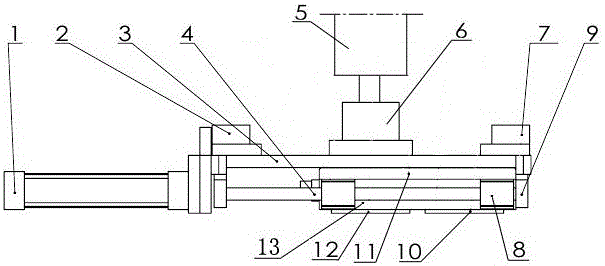

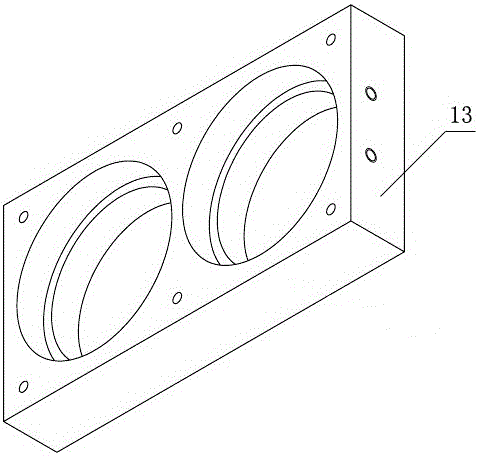

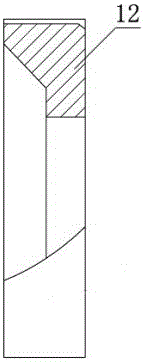

[0013] Embodiment, with reference to the accompanying drawings, a high-efficiency closing compactor at the filter bowl filter screen end of an automobile engine oil filter, including a main pressure cylinder 5, is characterized in that a main pressure cylinder is fixedly connected to the end of the piston rod of the main pressure cylinder 5 Mounting seat 6, a device fixed plate 3 is fixed on the main pressure cylinder mounting seat 6, and the two ends of device fixed plate 3 are provided with guide column mounting hole one 2 and guide column mounting hole two 7; Slide table 11 is arranged, and the two ends of slide table 11 are fixedly connected with reciprocating slide seat 8, and reciprocating slide seat 8 is movably contained on the device slideway 4, and the two ends of device slideway 4 are fixed on the fixed support 9; Die head fixed table 13 is housed below; Guide post installation hole one 2 and guide post installation hole two 7 are equipped with guide post, and guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com