Deep sea azimuth propulsion device

A full-turn propulsion and deep-sea technology, applied in the direction of propulsion transmission, transmission with synchronous propulsion components, ship propulsion, etc., can solve the problems of complex equipment structure, high production cost, and inability to realize three-dimensional continuous rotation, etc. Convenience, good sealing performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below.

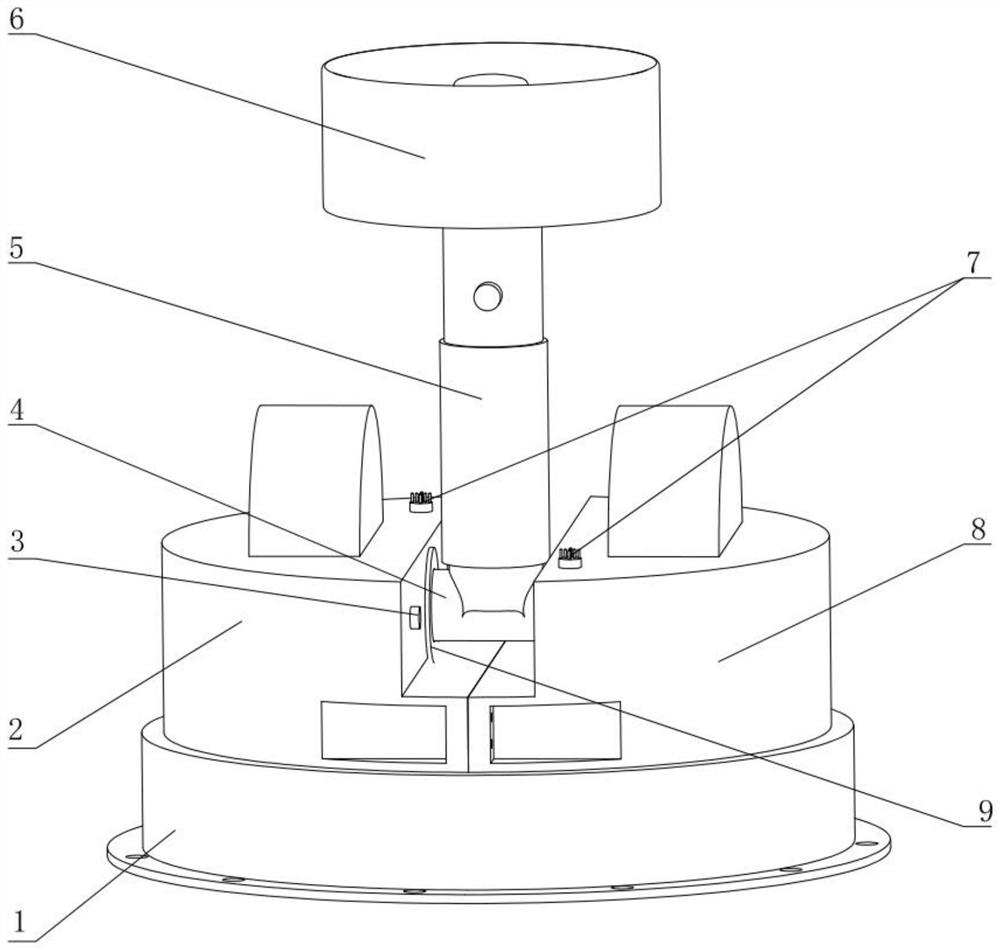

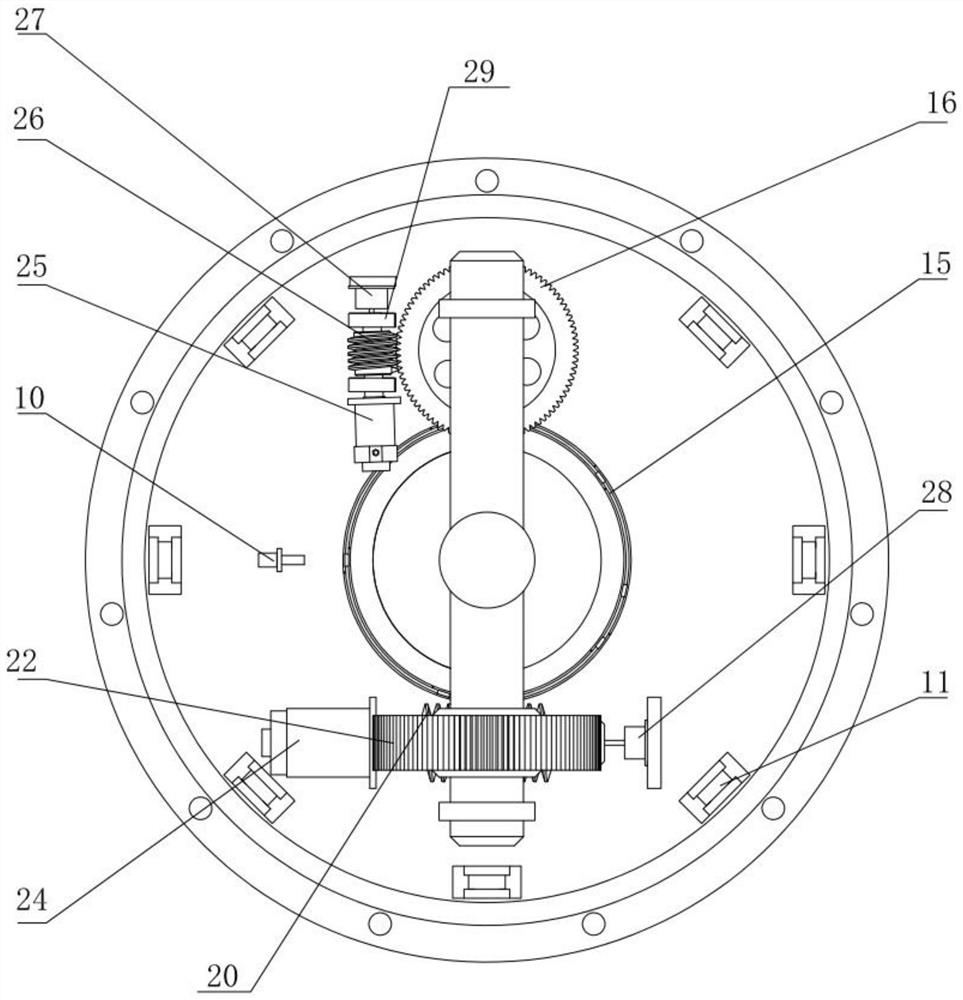

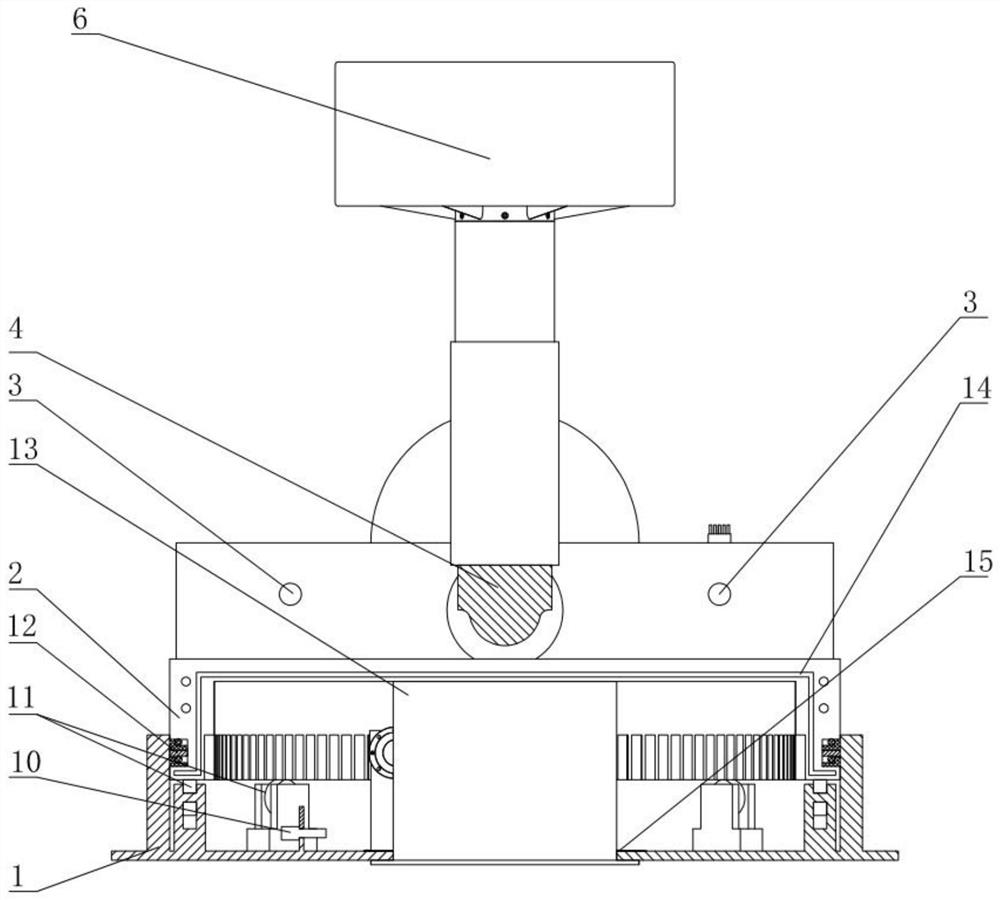

[0023] Such as figure 1 , figure 2 As shown, the deep-sea full-turn propulsion device includes a flange base 1. The flange base 1 is a circular base with a chamber, and a plurality of rotating rollers 11 are evenly distributed along the inner ring of the flange base 1 along the circumferential direction. In the blue base 1 and in contact with the rotating rollers 11, the rotating housing can slide relative to the rotating rollers 11 for guidance.

[0024] Such as figure 1 , image 3 and Figure 4 As shown, the rotating housing includes a first rotating housing 2 and a second rotating housing 8 affixed to each other, the first rotating housing 2 and the second rotating housing 8 are semicircular, and the first rotating housing 2 The outer ring of the second rotating housing 8 is compatible with the inner ring of the flange base 1, and the inner rings of the first rotating housing 2 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com