Glass placement rack for construction engineering

A technology for construction engineering and placing racks, which is applied in the direction of external frames, load hanging components, packaging, etc. It can solve the problems of inability to fold, large volume of glass placing racks, and inability to fix the top and bottom of the glass at the same time, so as to increase friction , reduced size, and stable placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

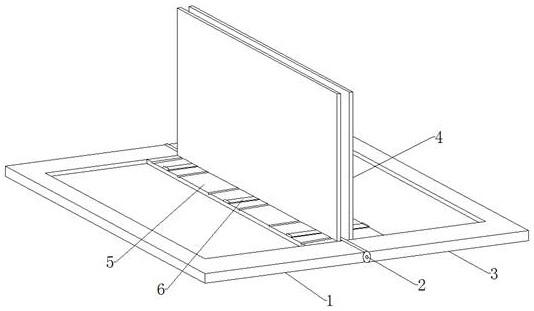

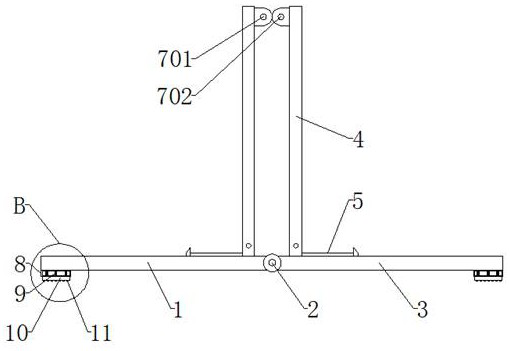

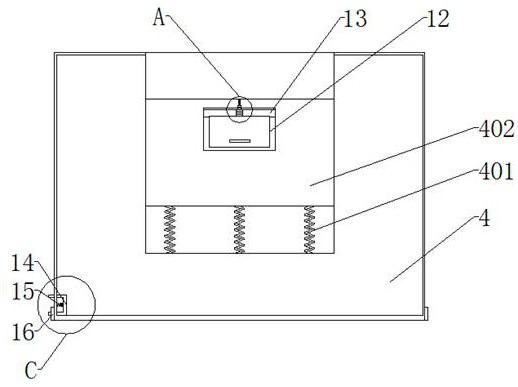

[0030] refer to Figure 1-7 , a glass placement frame for construction engineering, comprising a first bottom plate 1 and a second bottom plate 3, a first rotating shaft 2 is arranged between the first bottom plate 1 and the second bottom plate 3, and the first bottom plate 1 and the second bottom plate 3 are connected to each other. The first rotating shaft 2 is rotationally connected, and one side of the first bottom plate 1 and the second bottom plate 3 is provided with an opening, and the first bottom plate 1 and the second bottom plate 3 are all provided with a first slideway on the inner walls of both sides of the opening. Both the base plate 1 and the second base plate 3 are provided with a number of circular grooves at the first slideway, and the first base plate 1 and the second base plate 3 are all provided with a fixed structure at the first slideway, and the fixed structure includes a first sliding plate 4 and the fixed plate 5, the fixed plate 5 is fixedly connect...

Embodiment 2

[0039] refer to Figure 8 , a kind of glass placement frame for construction engineering. Compared with Embodiment 1, in order to facilitate the transportation of glass to high places, the device in this embodiment is more stable. One side of the first connecting shaft 701 and the second connecting shaft 702 are welded with For the same connecting plate 17, a cross bar 18 is welded between the inner walls of the two connecting plates 17, and an annular groove is opened in the middle of the cross bar 18. When the glass needs to be transported to a high place, the glass needs to be transported by a crane. The outside of the rod 18 is provided with an annular groove, which is more stable and convenient for transportation when transported by a crane.

[0040] When in use, by rotating the first sliding plate 4, the fixed plate 5 changes the angle with the rotation of the first sliding plate 4, and the glass is placed on the fixed plate 5, so that the bottom end of the glass can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com