Unified buffering device for closed loading and unloading operation

A buffer device and operation technology, which is applied in the direction of distribution device, special distribution device, liquid distribution, transportation or transfer device, etc., can solve the problems of dirty oil unloading pipe, laborious lifting, heavy oil unloading pipe, etc., and speed up the speed of oil unloading , the effect of reducing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

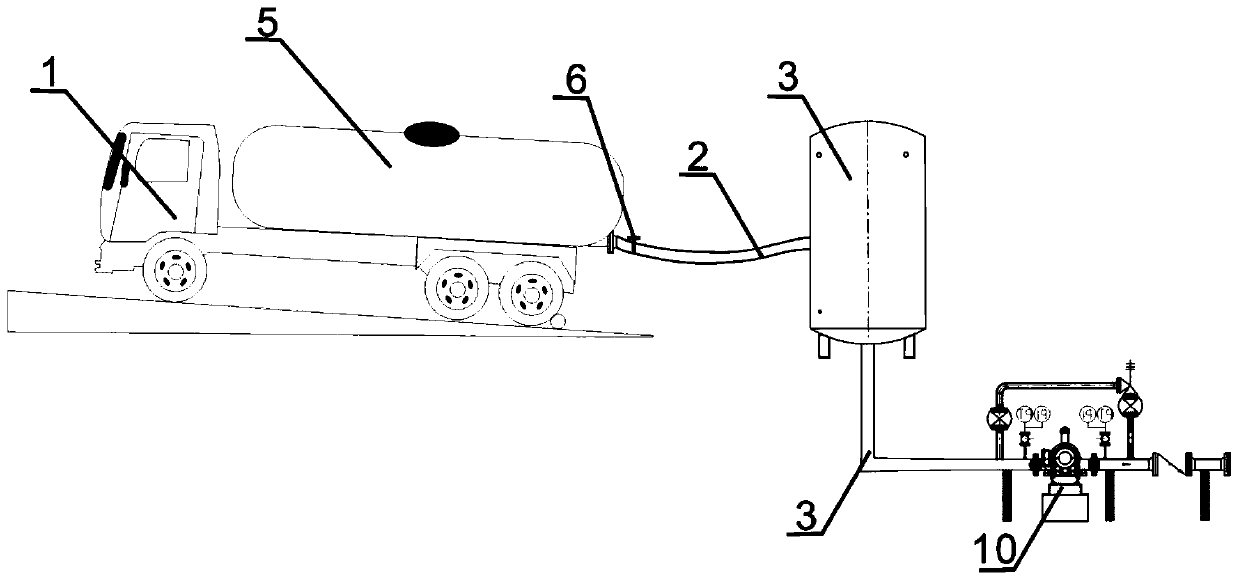

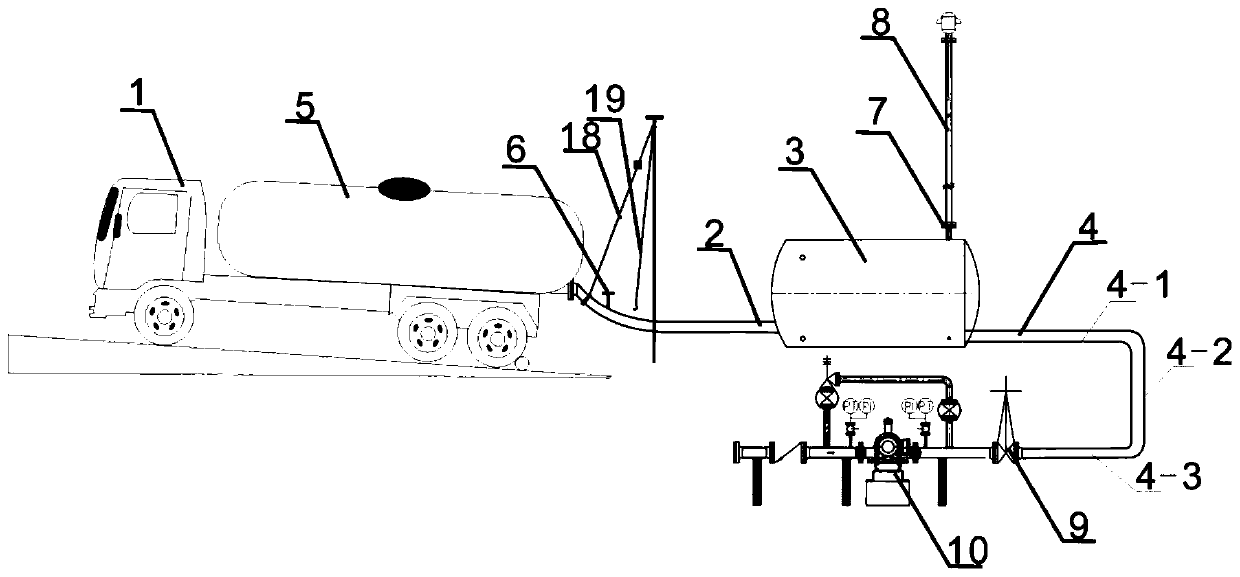

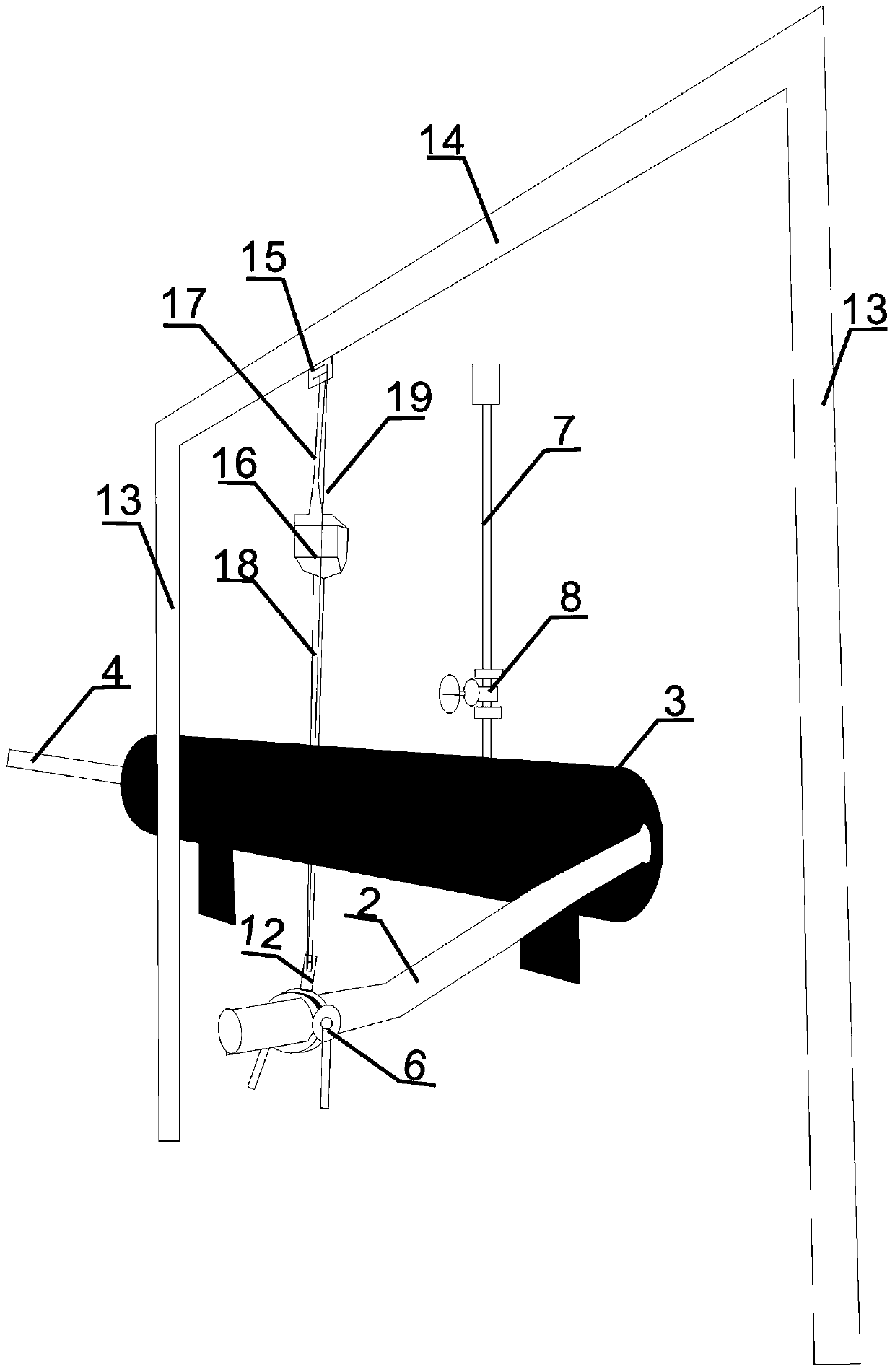

[0035] This embodiment is used for the integrated buffer device for airtight loading and unloading operations, including an adapter tank 3, one end of the adapter tank is connected to the oil discharge pipe 2, and the other end is the oil outlet pipe 4, and the circumference of the adapter tank 3 is provided with a row The air pipe 7, the electric valve I8 is arranged on the exhaust pipe 7;

[0036] The oil outlet pipe 4 is U-shaped, and the oil outlet pipe 4 is divided into pipe I4-1, pipe II4-2, and pipe III4-3. One end of the pipe I4-1 is connected to the oil storage tank 5, and the other end is connected to the The tube II4-2, one end of the tube III4-3 is connected to the tube II4-2, and the other end is connected to the oil storage tank 5, the tube I4-1 and the tube III4-3 are set up and down, and the tube II4-3 2 The pipe III 4-3 in the direction of the pipe III 4-3 is provided with an electric valve II 9 and a pump 10 in sequence;

[0037] The oil outlet pipe 4 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com