High-pressure sealing element and preparation method thereof

A high-pressure sealing and high-quality technology, applied in the field of material processing, can solve the problems of continuous production, low production efficiency, and poor durability of enterprises, and achieve the effects of improving comprehensive mechanical properties, increasing production efficiency, and reducing tissue stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

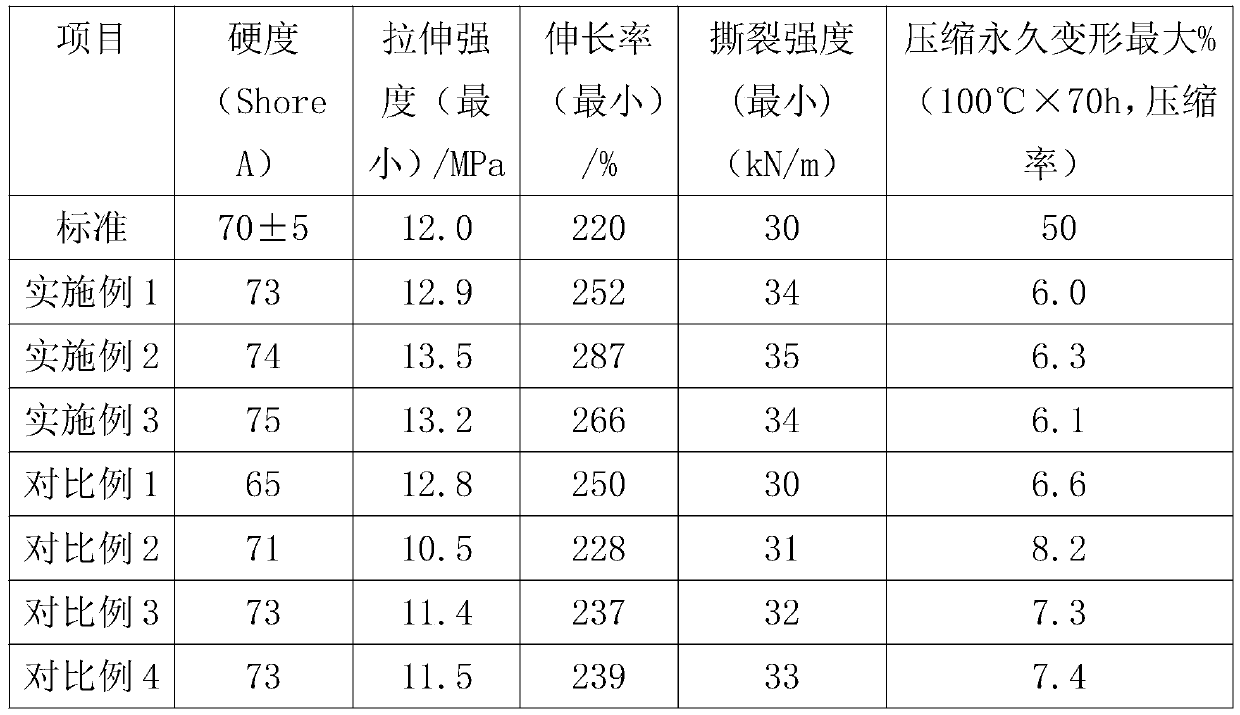

Examples

Embodiment 1

[0019] High-pressure seals, in parts by mass, consist of the following components:

[0020] JSRN250S 6 parts, JSRN240S 14 parts, semi-reinforcing N77025 parts, oil Plasthall-2262.4 parts, zinc oxide 1 part, stearic acid 0.2 parts, antioxidant RD 0.4 parts, antioxidant MB 0.2 parts, oleic acid amide CP 0.4 parts, Anti-scorch agent PVI 0.06 parts, DTDM 0.4 parts, S-800.08 parts, TMTD 0.1 parts, CZ 0.4 parts, TE 0.3 parts.

[0021] The method for preparing high-pressure seals includes the following steps: put JSRN250S, JSRN240S, and semi-reinforced N770 into an internal mixer for 2 minutes at a temperature of 180° C.; then add oil Plasthall-226 and knead for 3 minutes, unload Material, cooled to room temperature and put into the open mill, adding zinc oxide, stearic acid, anti-aging agent RD, anti-aging agent MB, oleic acid amide CP, anti-scorch agent PVI, fully mixed for 6min by double-roller rubber mixing machine, controlled The temperature is 160°C, the mixed rubber is prepar...

Embodiment 2

[0023] High-pressure seals, in parts by mass, consist of the following components:

[0024] JSRN250S 5 parts, JSRN240S 12 parts, semi-reinforcing N77023 parts, oil Plasthall-2262.2 parts, zinc oxide 0.5 parts, stearic acid 0.1 parts, antioxidant RD 0.3 parts, antioxidant MB 0.1 parts, oleic acid amide CP 0.3 parts, Anti-scorch agent PVI 0.05 parts, DTDM 0.3 parts, S-800.06 parts, CZ 0.3 parts, TE 0.2 parts.

[0025] The method for preparing high-pressure seals includes the following steps: put JSRN250S, JSRN240S, and semi-reinforced N770 into an internal mixer for mastication at 182°C for 2.5 minutes according to the mass parts of the raw materials; then add oil Plasthall-226 and knead for 5 minutes, Unload, cool to room temperature and put into the open mill, add zinc oxide, stearic acid, anti-aging agent RD, anti-aging agent MB, oleic acid amide CP, anti-scorch agent PVI, and use a double-roller rubber mixer to fully mix for 8 minutes. The temperature is controlled at 170°C...

Embodiment 3

[0027] High-pressure seals, in parts by mass, consist of the following components:

[0028] 7 parts of JSRN250S, 15 parts of JSRN240S, 26 parts of semi-reinforcing N7702, 2.5 parts of oil Plasthall-226, 1.5 parts of zinc oxide, 0.3 parts of stearic acid, 0.5 parts of anti-aging agent RD, 0.3 parts of anti-aging agent MB, 0.5 parts of oleic acid amide CP, Anti-scorch agent PVI 0.07, DTDM 0.5, S-800.09, TMTD 0.2, CZ 0.5, TE 0.4.

[0029] The method for preparing high-pressure seals includes the following steps: put JSRN250S, JSRN240S, and semi-reinforced N770 into an internal mixer for 3 minutes at a temperature of 186° C.; then add oil Plasthall-226 and knead for 8 minutes, unload material, cooled to room temperature and put into the open mill, adding zinc oxide, stearic acid, anti-aging agent RD, anti-aging agent MB, oleic acid amide CP, anti-scorch agent PVI, using a double-roller rubber mixing machine to fully mix for 7min, control The temperature is 165°C, the mixed rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com