A kind of antibacterial light textile fabric and preparation method thereof

A kind of textile fabric and light technology, applied in the field of textile fabrics, can solve the problem that the fabric cannot meet the health, antibacterial, intelligent temperature and comfort of the fabric at the same time, and achieves good temperature regulation and anti-ultraviolet and far-infrared effects. Antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

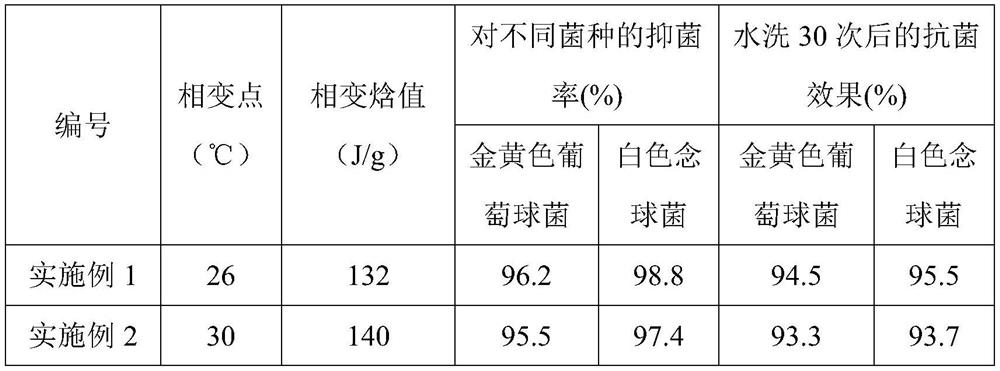

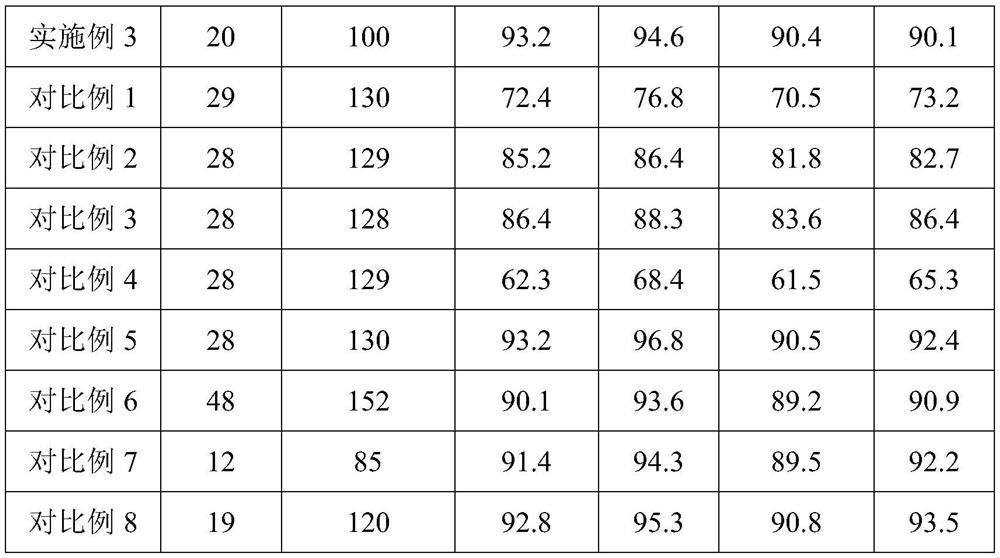

Embodiment 1

[0060] Embodiment 1 provides an antibacterial lightweight textile fabric, and the antibacterial lightweight textile fabric is woven from antibacterial temperature-regulating aerogel fibers.

[0061] The preparation method of the antibacterial temperature-adjusting aerogel fiber is as follows: polyester chips are melted to obtain polyester spinning solution, and then modified aerogel and negative ion temperature-adjusting material are added to the spinning solution, wherein the polyester spinning solution, The mass ratio of the modified aerogel and the negative ion temperature-adjusting material is 1:0.2:0.12, and the mixture is uniform; then it is sprayed out through the spinneret, and then the fiber is formed, the primary fiber is drawn and oriented, and the fiber is heat-set and wound. Antibacterial temperature-adjusting aerogel fibers were obtained.

[0062] The preparation method of the modified aerogel is as follows: at 0 to 4° C., a silver nitrate solution with a concent...

Embodiment 2

[0076] The difference between embodiment 2 and embodiment 1 is:

[0077] The preparation method of the antibacterial temperature-adjusting aerogel fiber is as follows: polyester chips are melted to obtain polyester spinning solution, and then modified aerogel and negative ion temperature-adjusting material are added to the spinning solution, wherein the polyester spinning solution, The mass ratio of the modified aerogel and the negative ion temperature-adjusting material is 1:0.23:0.15, and the mixture is uniform; then it is sprayed out through the spinneret hole, and then subjected to fiber forming, primary fiber drawing and orientation, fiber heat-setting and winding to make the product. Antibacterial temperature-adjusting aerogel fibers were obtained.

[0078] The preparation method of the modified aerogel is as follows: at 0 to 4° C., a silver nitrate solution with a concentration of 2.3 g / L is added to a chlorogenic acid solution with a concentration of 3.8 g / L, and the s...

Embodiment 3

[0080] The difference between Example 3 and Example 1 is:

[0081]The preparation method of the antibacterial temperature-adjusting aerogel fiber is as follows: polyester chips are melted to obtain polyester spinning solution, and then modified aerogel and negative ion temperature-adjusting material are added to the spinning solution, wherein the polyester spinning solution, The mass ratio of the modified aerogel and the negative ion temperature-adjusting material is 1:0.18:0.09, and the mixture is uniform; then it is sprayed out through the spinneret, and then through fiber forming, primary fiber drawing orientation, fiber heat-setting and winding, the system is prepared. Antibacterial temperature-adjusting aerogel fibers were obtained.

[0082] The preparation method of the modified aerogel is as follows: at 0 to 4° C., a silver nitrate solution with a concentration of 2.3 g / L is added to a chlorogenic acid solution with a concentration of 3.8 g / L, and the sol is added immed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com