A composite prefabricated floor slab for a low-rise prefabricated steel structure residence

A prefabricated, steel structure technology, applied in the direction of floor slabs, building components, building structures, etc., can solve the problems of not complying with the concept of environmental protection, cannot be reused, and difficult to recycle as a whole, achieve high mechanical strength and mechanical properties, reduce Construction cost, effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

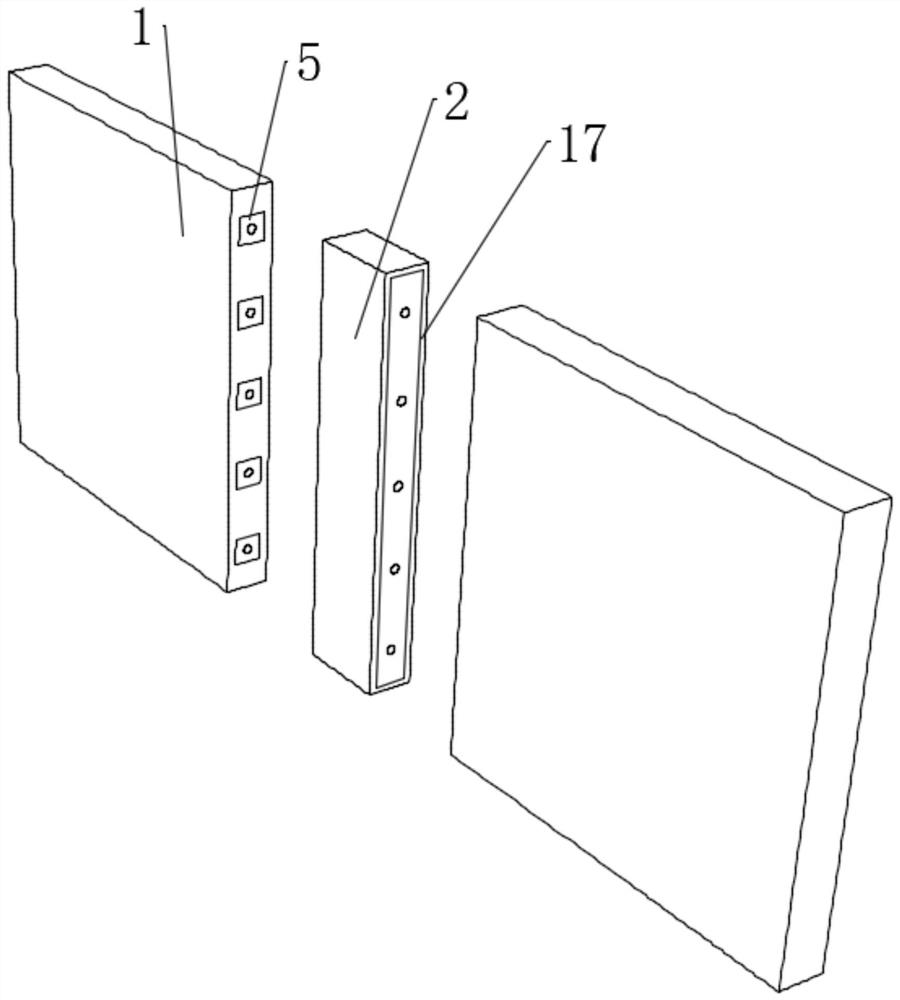

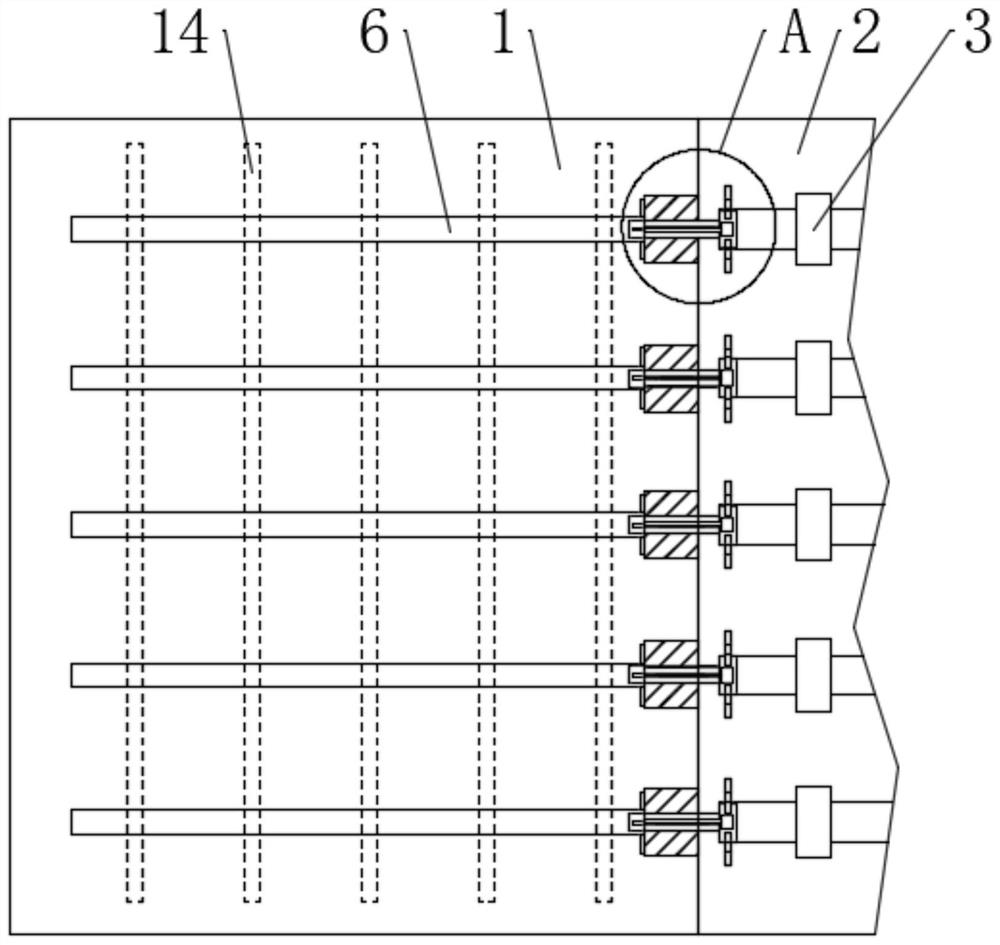

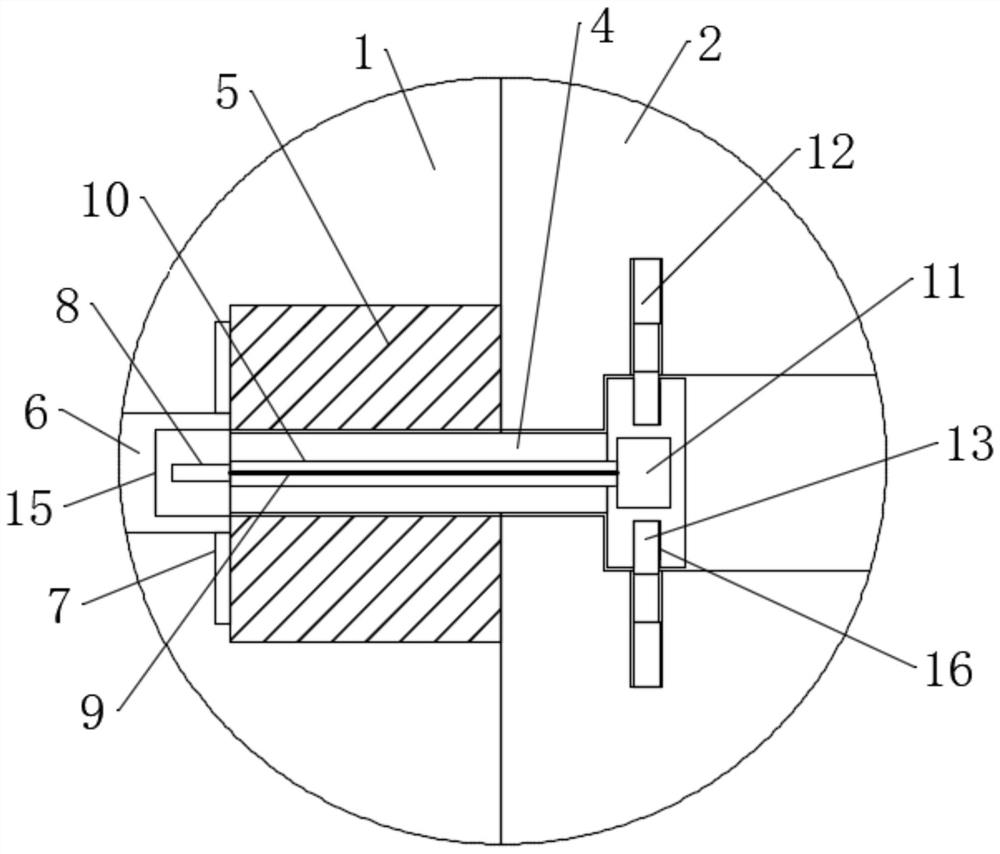

[0051] see Figure 1-4 , a combined prefabricated floor slab for low-rise prefabricated steel structure residences, including a prefabricated slab 1 and a connector 2, the connector 2 is made of stainless steel, and a number of evenly distributed displacement cavities are excavated on the connector 2, and the displacement cavities A rotating magnetic field generator 3 is installed to generate a huge rotating magnetic field through current changes. The rotating magnetic field generator 3 is a prior art, and its structure and circuit connection will not be repeated here. A number of through holes are dug at the left and right ends of the connector 2 , and the through hole communicates with the displacement cavity, and the displacement cavity is provided with a matching magnetic bolt 4, the magnetic bolt 4 includes a magnetic head 401 and a screw portion 402, the magnetic head 401 is matched with the displacement cavity, and the prefabricated plate 1 There are a number of fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com