Plate paneling locking system

A locking system and paneling technology, which is applied in the direction of floors, buildings, building structures, etc., can solve the problems of inability to realize the side connection of adjacent floors, difficulty in ensuring installation accuracy, and inability to be widely used. It achieves simple structure, The effect of high connection strength and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

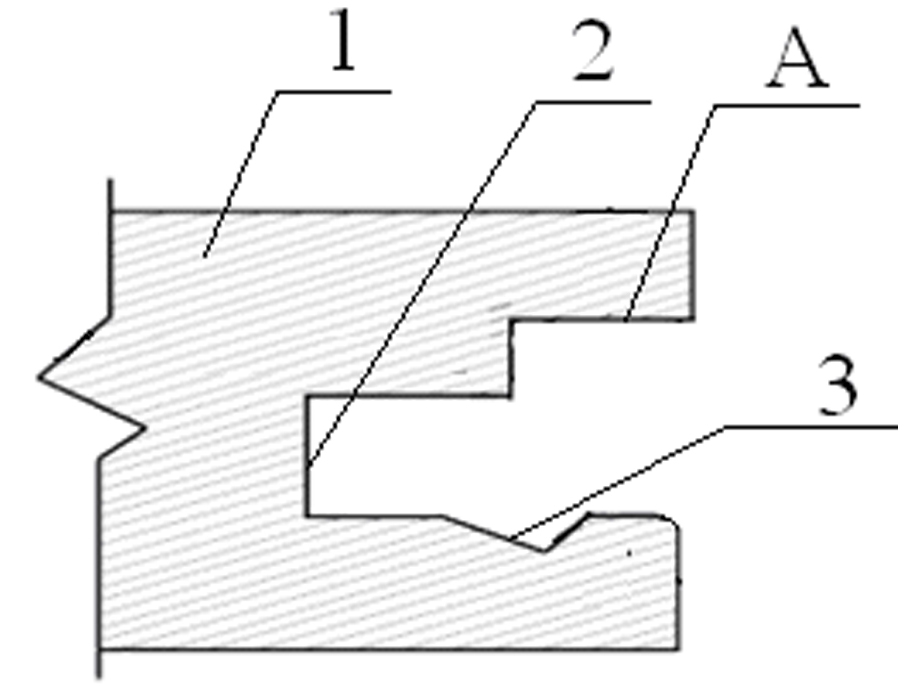

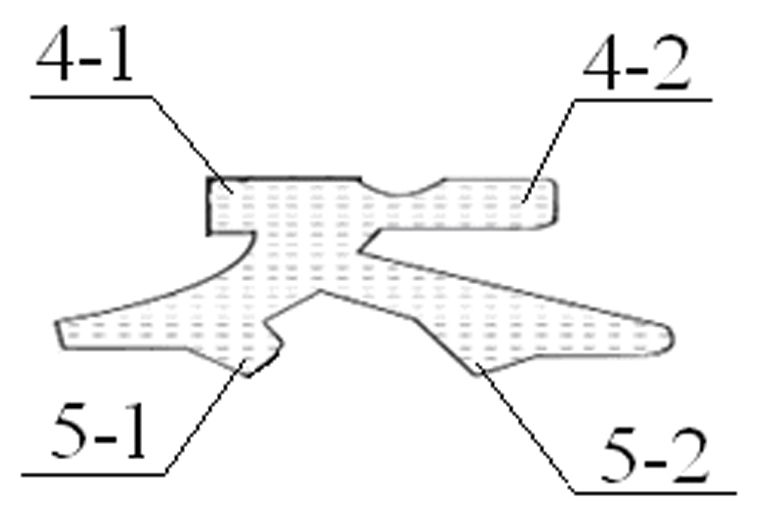

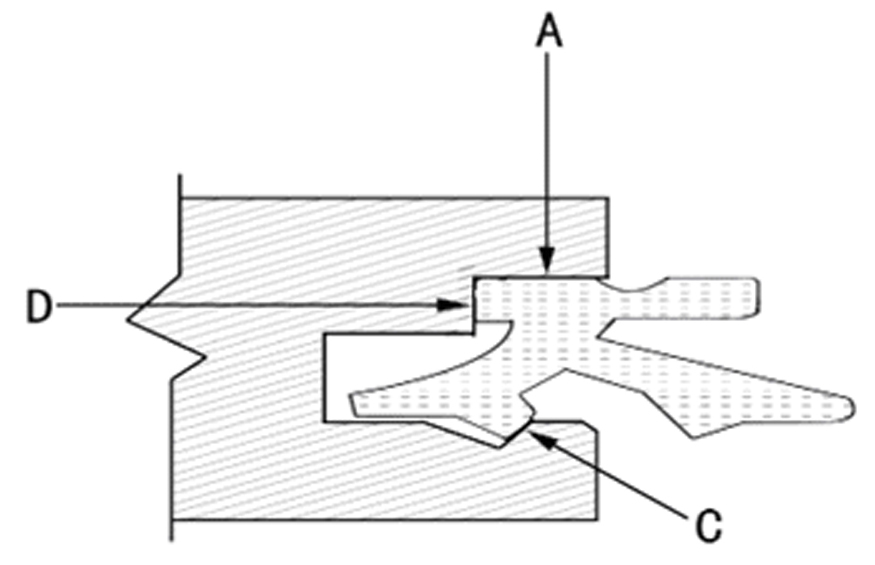

[0034] refer to figure 1 , 2 , this embodiment includes a floor body 1 and a connector body, the peripheral side of the floor body 1 is provided with grooves 2 of the same shape and size, and one side of the groove 2 is provided with an indented locking groove 3; the connector Main tongue I4-1 and main tongue II4-2 are respectively arranged on both sides of the main body, and the main tongue I4-1 and main tongue II4-2 are all adapted to the side groove 2 around the floor body, and the lower part of the connector body Sub-tongue Ⅰ5-1, sub-tongue Ⅱ5-2 are respectively provided, and sub-tongue Ⅰ5-1 and sub-tongue Ⅱ5-2 are all compatible with the inset locking groove 3 on the side of the side groove 2 around the floor body match.

[0035] The fit between the auxiliary tongue I5-1 and the auxiliary tongue II5-2 and the inset locking groove on the side of the peripheral side groove of the floor body is an interference fit.

[0036] The upper end surfaces of the main tongue I4-1 ...

Embodiment 2

[0042] refer to figure 1 , 5 , the difference between this embodiment and embodiment 1 is that the shape of the connector is like " ⊥ " shape, and the material is hard wood, and the floor body is rectangular, and the material is reinforced wood. All the other are the same as embodiment 1.

Embodiment 3

[0044] refer to Image 6 , 7 The difference between this embodiment and Embodiment 1 is that the side grooves around the floor body are trapezoidal grooves, the material of the floor body is cork, and the shape of the connectors is trapezoidal. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com