Constructional-column top steel bar embedded structure assembly and method for installation and construction of constructional-column top steel bars

A technology of structural components and structural columns, which is applied in the direction of structural elements, building components, building structures, etc., can solve the problem that the formwork at the top of the structural columns is difficult to remove, and achieve the goals of reducing the cost of planting bars, ensuring construction quality, and reducing construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A reinforced pre-embedded structural component at the top of a structural column:

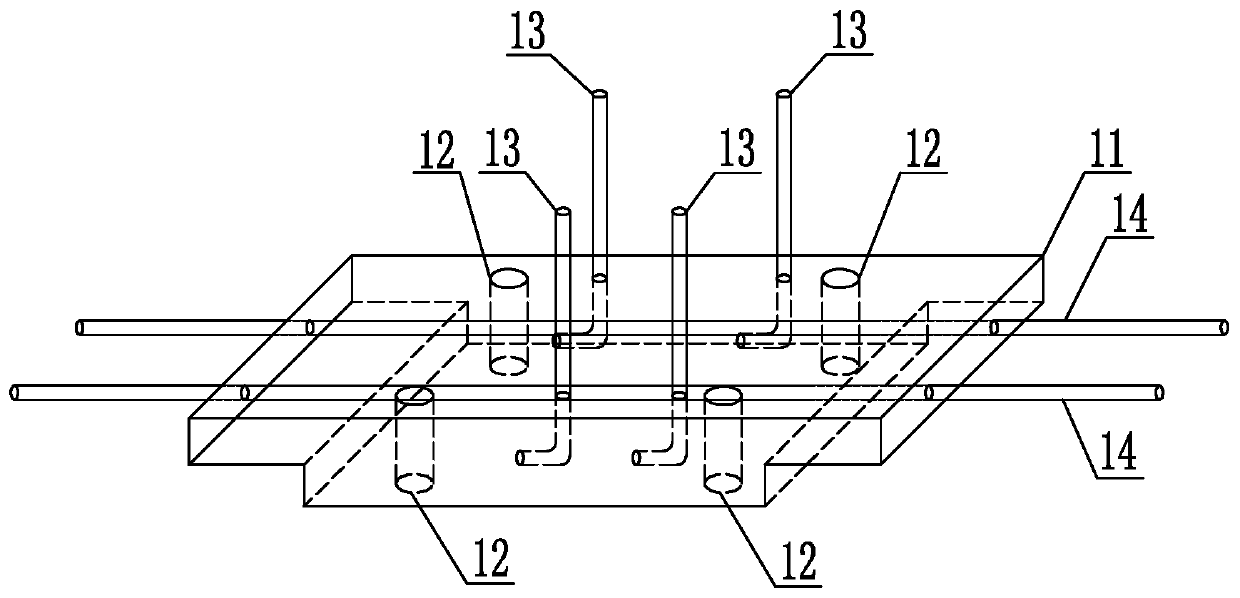

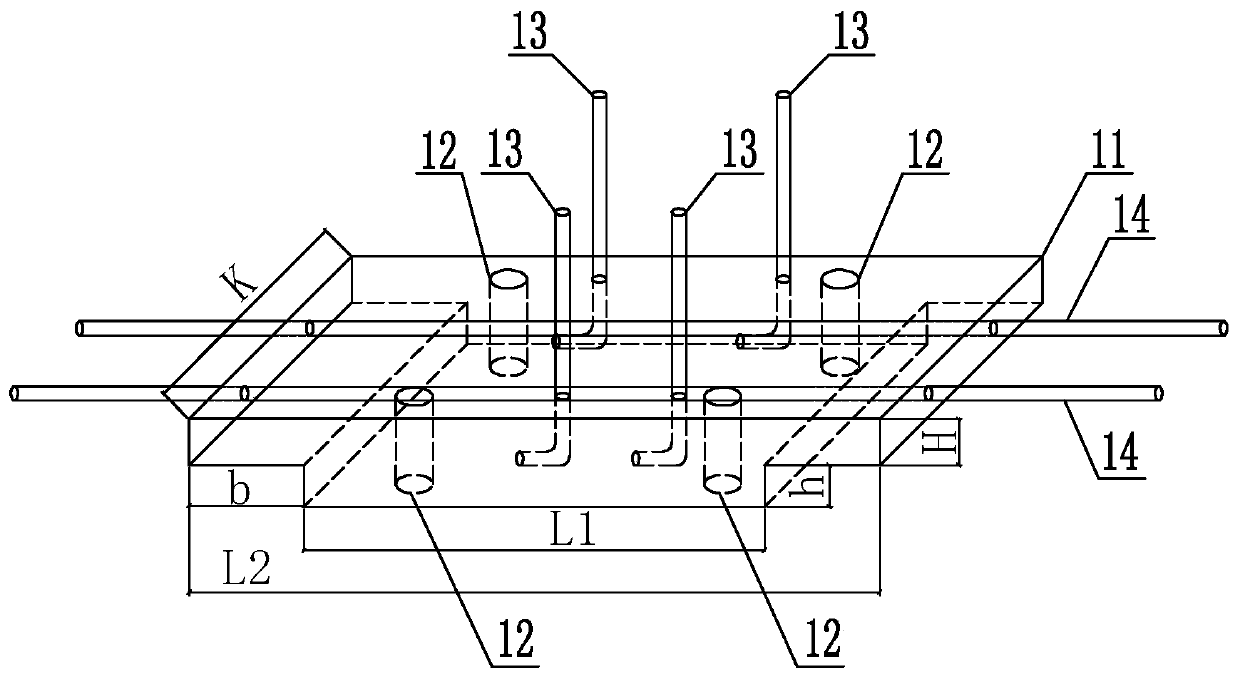

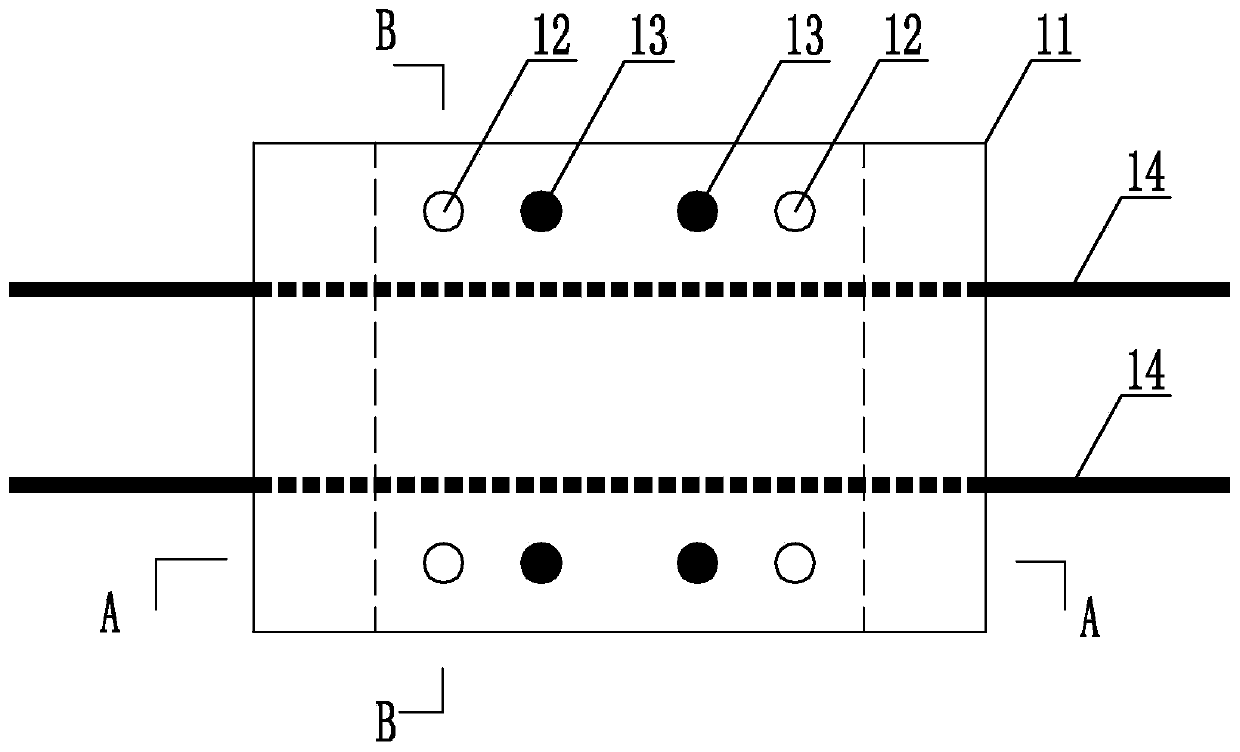

[0063] The reinforced pre-embedded structural component 1 at the top of the structural column is a semi-finished concrete prefabricated component, such as Figure 1-Figure 5 as shown,

[0064] The reinforced pre-embedded structure assembly at the top of the structural column includes a concrete prefabricated body 11, a longitudinal tie bar 13, a transverse tie bar 14 and an anti-cracking net 15;

[0065] The concrete prefabricated part body 11 is a rectangular parallelepiped with unequal cross-section, and there is a longitudinally penetrating prefabricated steel reinforcement hole 12 at the top of the structural column on the concrete prefabricated part body;

[0066] The concrete strength of the anti-concrete prefabricated part body 11 is higher than or equal to the concrete strength of the structural member at the top of the structural column; the concrete prefabricated part body 11 ...

Embodiment 2

[0071] A method for installing and constructing steel bars at the top of a structural column:

[0072] It is a method of using the pre-embedded structure assembly at the top of the construction column described in Embodiment 1 for the installation and construction of the reinforcement at the top of the construction column, that is, the above-mentioned pre-embedded structure assembly 1 for the reinforcement at the top of the construction column is directly installed at the assembly position of the template at the top of the construction column The height H of the upper part of the concrete prefabricated part body 11 of the reinforced pre-embedded structural assembly 1 at the top of the structural column is the thickness of the protective layer of steel bars at the top of the structural column. After the installation is completed, it can also be used as a spacer for the component. Installation and construction of the top member reinforcement. After the installation of the top mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com