Medical airtight door

An airtight door and door frame technology, applied in the field of medical airtight doors, can solve the problems of easy fogging, poor air tightness, and inability to detect sealing, etc., and achieve the effect of strong air tightness and preventing fogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

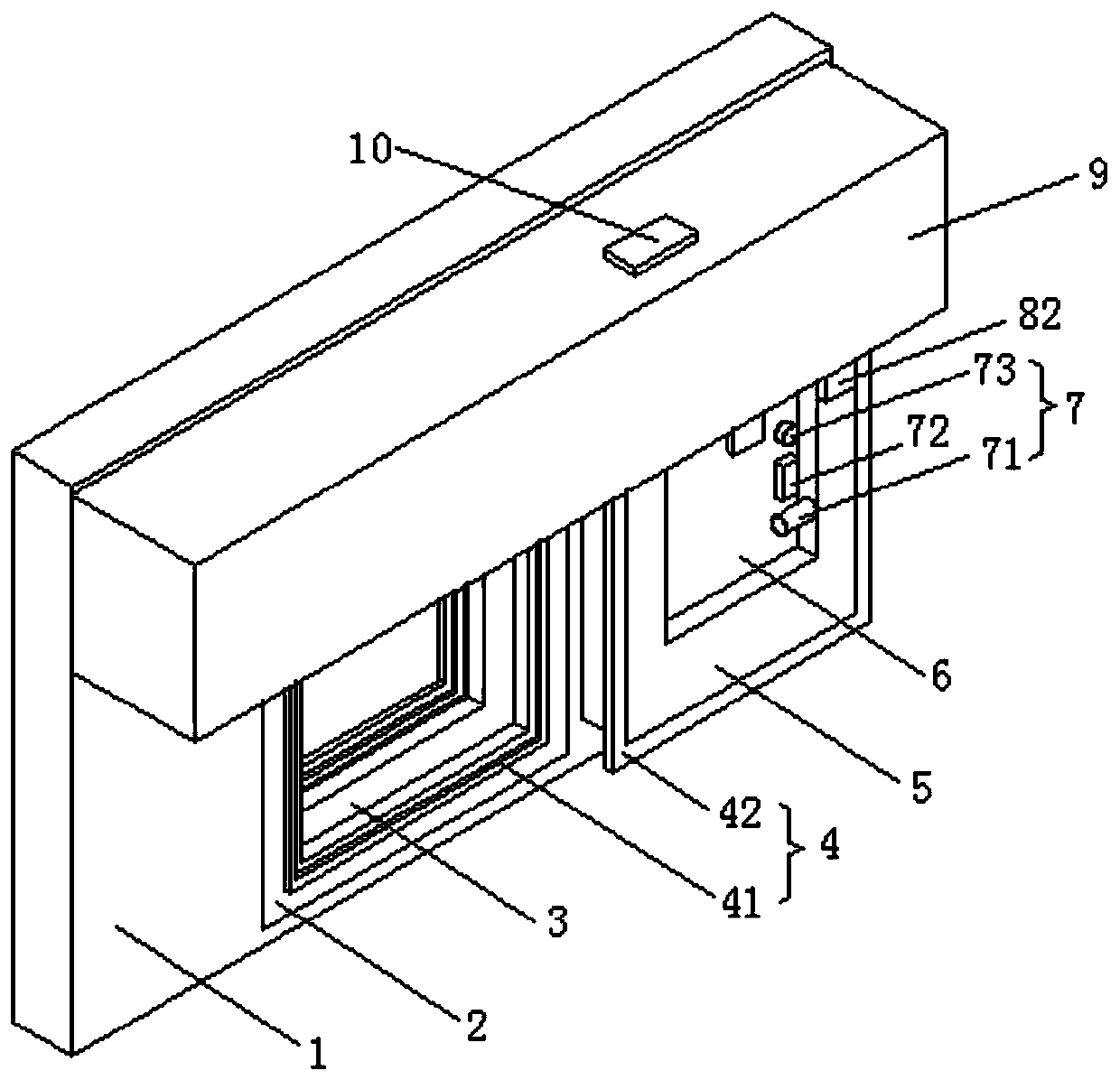

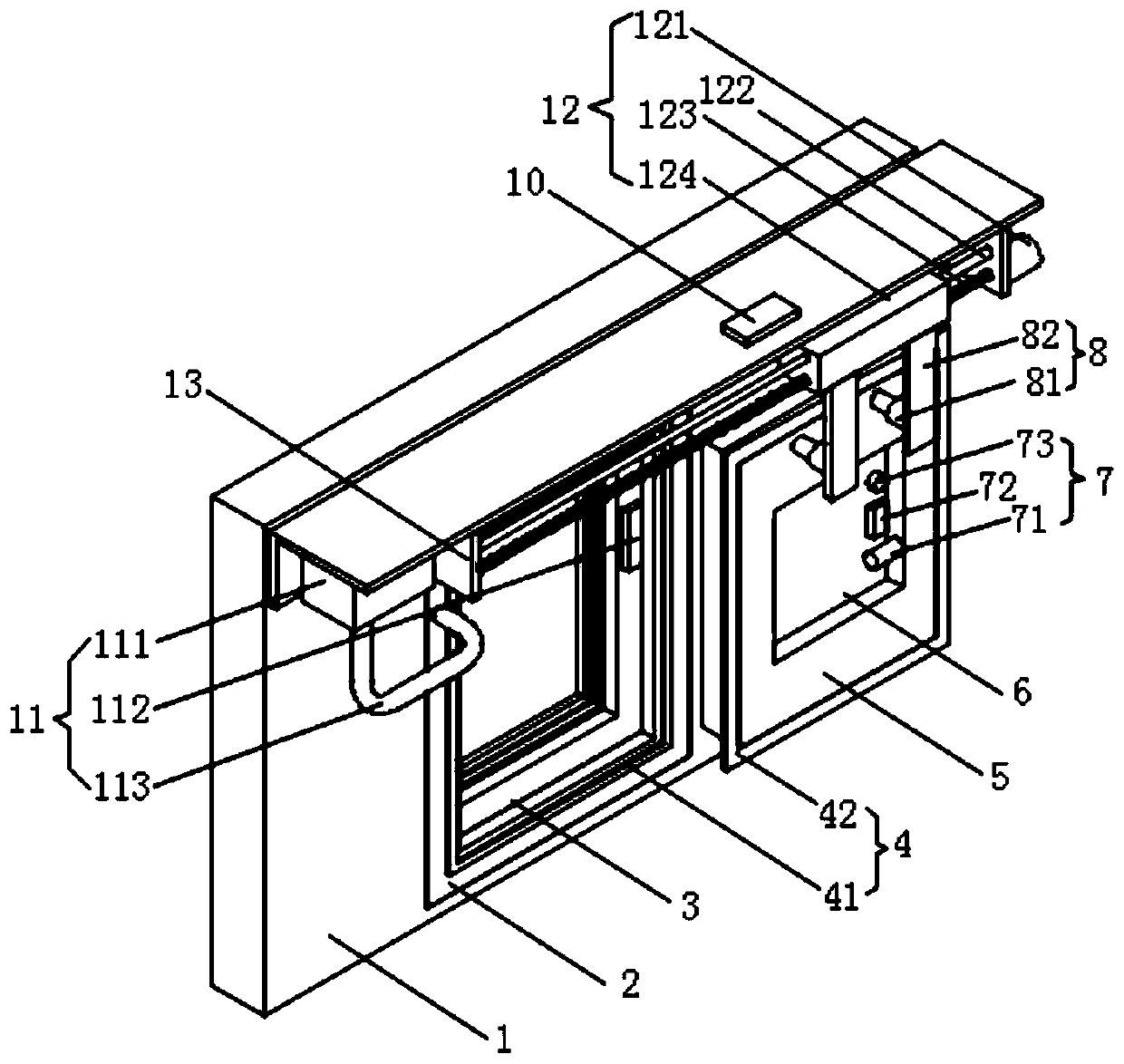

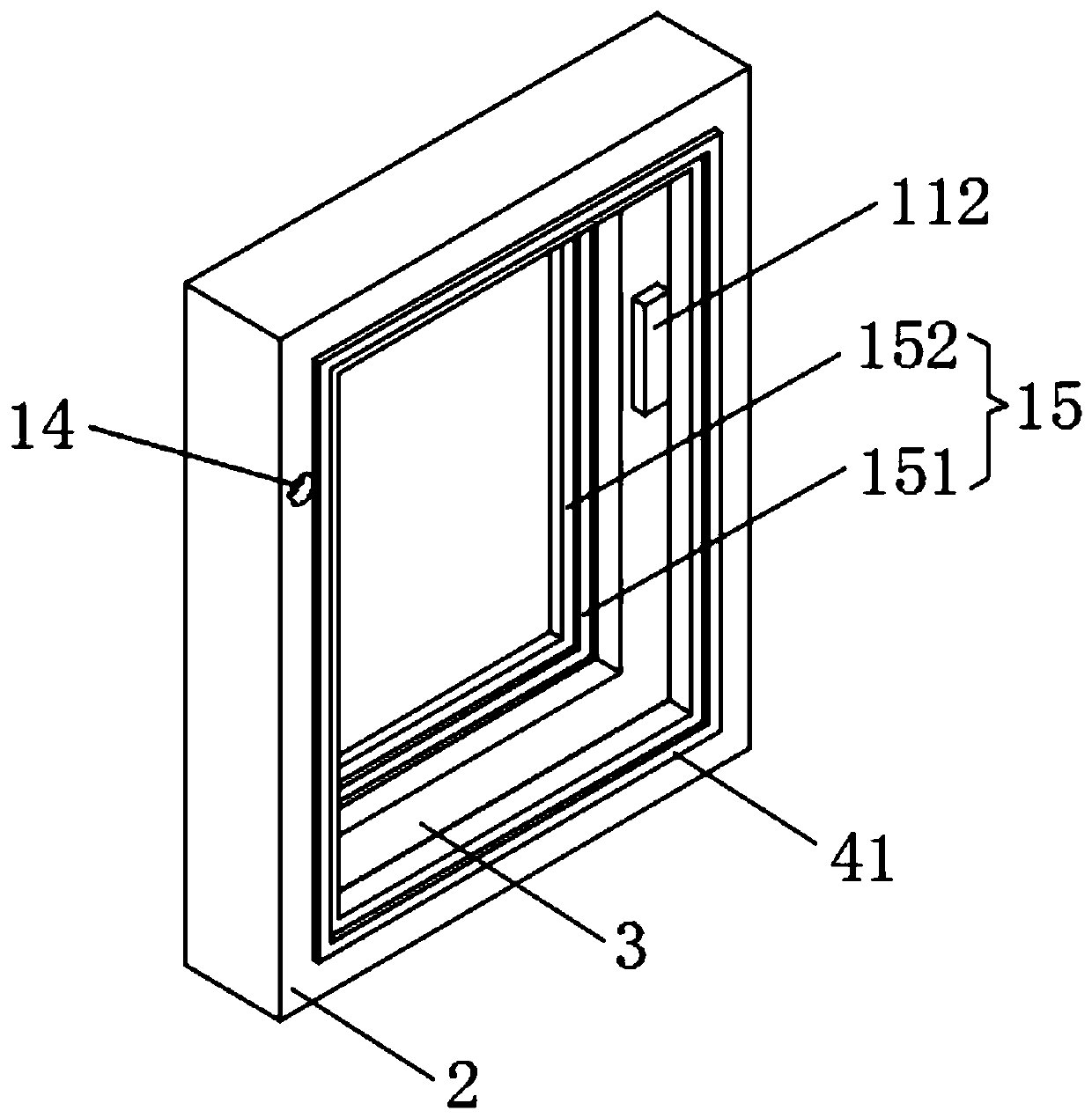

[0022] A medical airtight door, comprising a door frame 2, a mounting frame 9 and a door body 5, a door frame 2 is arranged in a through groove of the wall body 1, an annular groove 3 is opened on the inner wall of the door frame 2, and an annular groove 3 is arranged on the inner wall of the door frame 2, and the rear side of the annular groove 3 is provided on the inner wall of the door frame 2. There is an inner sealing unit 15, a through hole 14 is opened on the upper left side of the front side of the door frame 2, the mounting frame 9 is arranged on the wall 1, and is located above the door frame 2, and a detection unit 11 is provided in the mounting frame 9 and the annular groove 3 , the installation frame 9 is provided with a left-right symmetrical fixed plate 13, a reciprocating unit 12 is arranged between the two fixed plates 13, a telescopic unit 8 is provided on the reciprocating unit 12, and the door body 5 is arranged on the telescopic unit 8, and is connected with...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is:

[0026] In this embodiment, the outer sealing unit 4 includes an outer sealing gasket 41 and an outer sealing frame 42, the outer sealing gasket 41 is arranged on the inner wall of the door frame 2 at the front side of the annular groove 3, and the outer sealing frame 42 is arranged in front of the four sides of the door body 5. On the side, the outer gasket 41 corresponds to the outer sealing frame 42 .

[0027] Reciprocating unit 12 comprises servo motor 121, guide rod 122, screw mandrel 123 and slide block 124, is connected with screw mandrel 123 by bearing rotation between two fixed plates 13, is fixed with screw mandrel 123 parallel with screw mandrel 123 between two fixed plates 13 The guide rod 122, the screw mandrel 123 and the side of the slider 124 are threaded through screw holes, the guide rod 122 and the side of the slider 124 are slidably connected through the slide hole, and the servo motor 121 ...

Embodiment 3

[0030] The difference between this embodiment and Embodiment 1 is:

[0031] In this embodiment, the telescopic unit 8 includes an electric telescopic rod 81 and two connecting plates 82. The lower surface of the slider 124 is provided with a symmetrical connecting plate 82, and the rear side of the connecting plate 82 is provided with an electric telescopic rod 81. The end of the rod 81 is connected to the upper end of the front side of the door body 5 , and the electric telescopic rod 81 is electrically connected to the PLC controller 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com