High-precision pile body omnibearing monitoring method based on fiber bragg grating

A fiber grating, high-precision technology, used in measuring devices, mapping and navigation, measuring inclination and other directions, can solve the problems of low efficiency, complex operation, poor accuracy, etc., to achieve the effect of low material cost, simple production and real-time response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

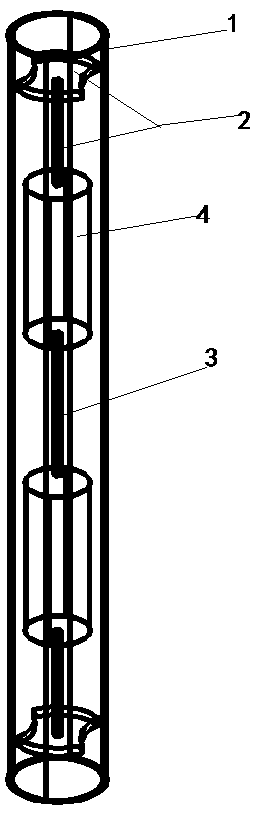

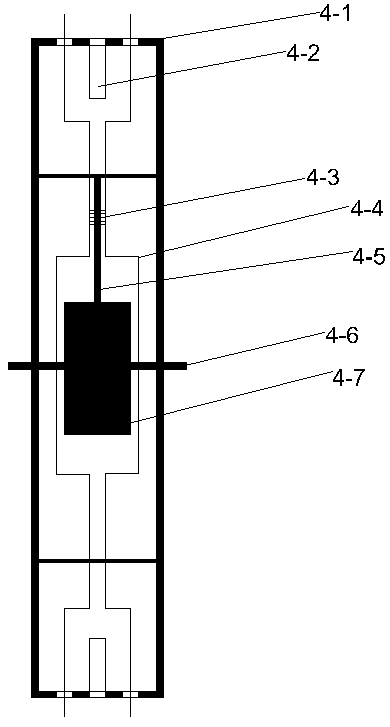

[0015] Step 1. Make the sensor according to the requirements of the plan. The sensor includes the outer wall of the sensor, fiber grating, cantilever beam, gravity pendulum, and sensing optical fiber. At both ends of the sensor, a threaded hole is reserved for connection, and two holes are used for sensing. Optical fiber channel

[0016] Step 2. Connect two fiber grating inclination sensors, and design the threaded connection screw rod with the threaded holes reserved at both ends of the sensor. The diameter is 10mm, the length is 120mm, and the effective thread distance is 30mm;

[0017] Step 3. Manufacturing method, including ABS rigid tube, threaded fixing part, threaded connecting rod, fiber grating inclination sensor, ABS tube is used as the outer tube of the method, the threaded fixing part connects the ABS tube and the sensor into a whole, the total length of the threaded fixing part The diameter of the disc is 90mm, the diameter of the disc is 55mm, and the thickness is 10m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com