Electro-hydraulic servo biaxial pipeline fatigue test device

An electro-hydraulic servo and fatigue test technology, which is applied in the direction of measuring device, testing material hardness, testing material strength by applying repetitive force/pulsation force, etc., can solve the problems of difficult testing of the hardness of different lengths of pipes and difficult estimation of pipe data, etc. Achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

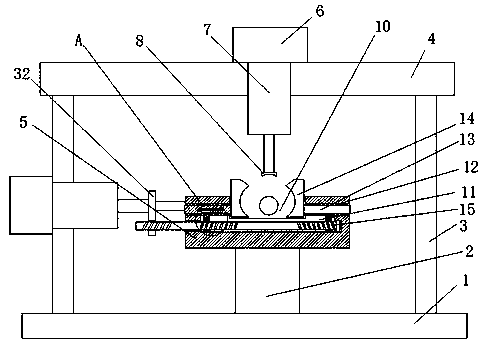

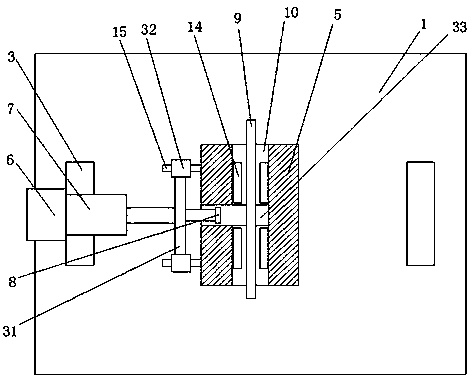

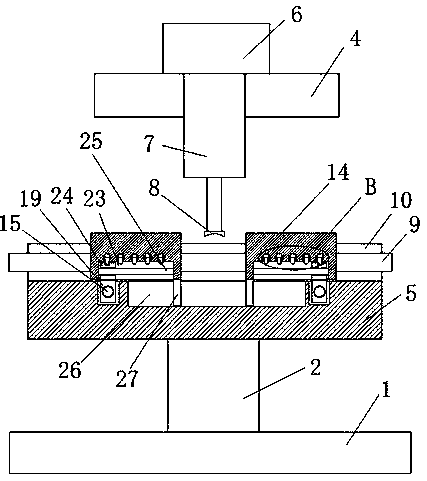

[0027] refer to Figure 1-5 , an electro-hydraulic servo biaxial pipeline fatigue test device, including a base 1, two mutually symmetrical support plates 3 are fixedly installed on the top of the base 1, the same cover plate 4 is fixedly installed on the top of the two support plates 3, and the base 1 A support seat 2 is fixedly installed on the top of the cover plate 4, and a controller 6 is fixedly installed on the top of the cover plate 4 and the support plate 3 on one side. The controller 6 is fixedly connected with a hydraulic cylinder 7, and the piston of the hydraulic cylinder 7 is fixedly installed with an arc shaped top plate 8, the top of the support seat 2 is fixedly equipped with an operation table 5, and the top of the operation table 5 is provided with a placement groove 10, and the pipe material 9 is placed in the placement groove 10, and two symmetrically arranged on the bottom inner wall of the placement groove 10. Sliding groove 11, rotating rod 15 is connec...

Embodiment 2

[0038] refer to Figure 1-5, an electro-hydraulic servo biaxial pipeline fatigue test device, including a base 1, two mutually symmetrical support plates 3 are welded on the top of the base 1, the same cover plate 4 is welded on the top of the two support plates 3, and the top of the base 1 A support seat 2 is welded, a controller 6 is welded on the top of the cover plate 4 and the support plate 3 on one side, the controller 6 is fixedly connected with a hydraulic cylinder 7, and the piston of the hydraulic cylinder 7 is welded with an arc-shaped top plate 8, supporting The top of the seat 2 is welded with an operation table 5, and the top of the operation table 5 is provided with a placement groove 10, and the pipe material 9 is placed in the placement groove 10, and two symmetrically arranged sliding grooves 11 are provided on the bottom inner wall of the placement groove 10. 11 is connected with a rotary rod 15 for rotation, and one end of the rotary rod 15 runs through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com