Intelligent dry burning preventive method and system

An anti-dry burning and dry burning technology, applied in the field of kitchen utensils, can solve the problems of inaccurate identification, inability to adjust, cost, etc., and achieve the effects of improving accuracy, reducing identification errors, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

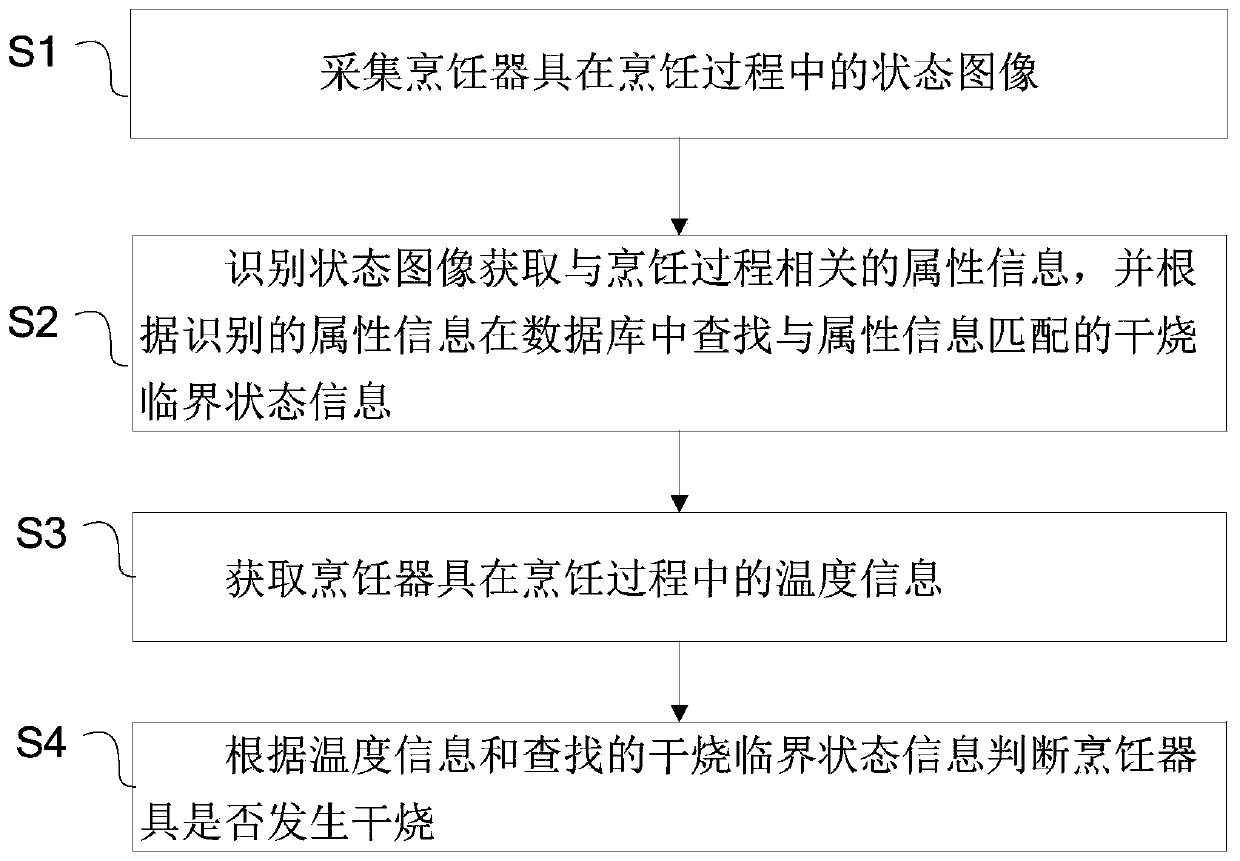

[0055] This example provides an intelligent anti-dry method, the anti-dry method is applied to control the stove dry, the specific control flow chart is as follows figure 1 As shown, it specifically includes the following steps.

[0056] S1: Collect state images of the cooking appliance during the cooking process.

[0057] S2: Identify the state image to obtain attribute information related to the cooking process, and search the database for critical state information of dry cooking that matches the attribute information according to the identified attribute information.

[0058] Wherein, the attribute information related to the cooking process of the cooking utensil and the dry-boil critical state of the cooking utensil associated with the attribute information are stored in the database.

[0059] S3: Obtain the temperature information of the cooking utensil during the cooking process;

[0060] S4: Determine whether the cooking utensil is dry-boiled according to the tempera...

Embodiment 2

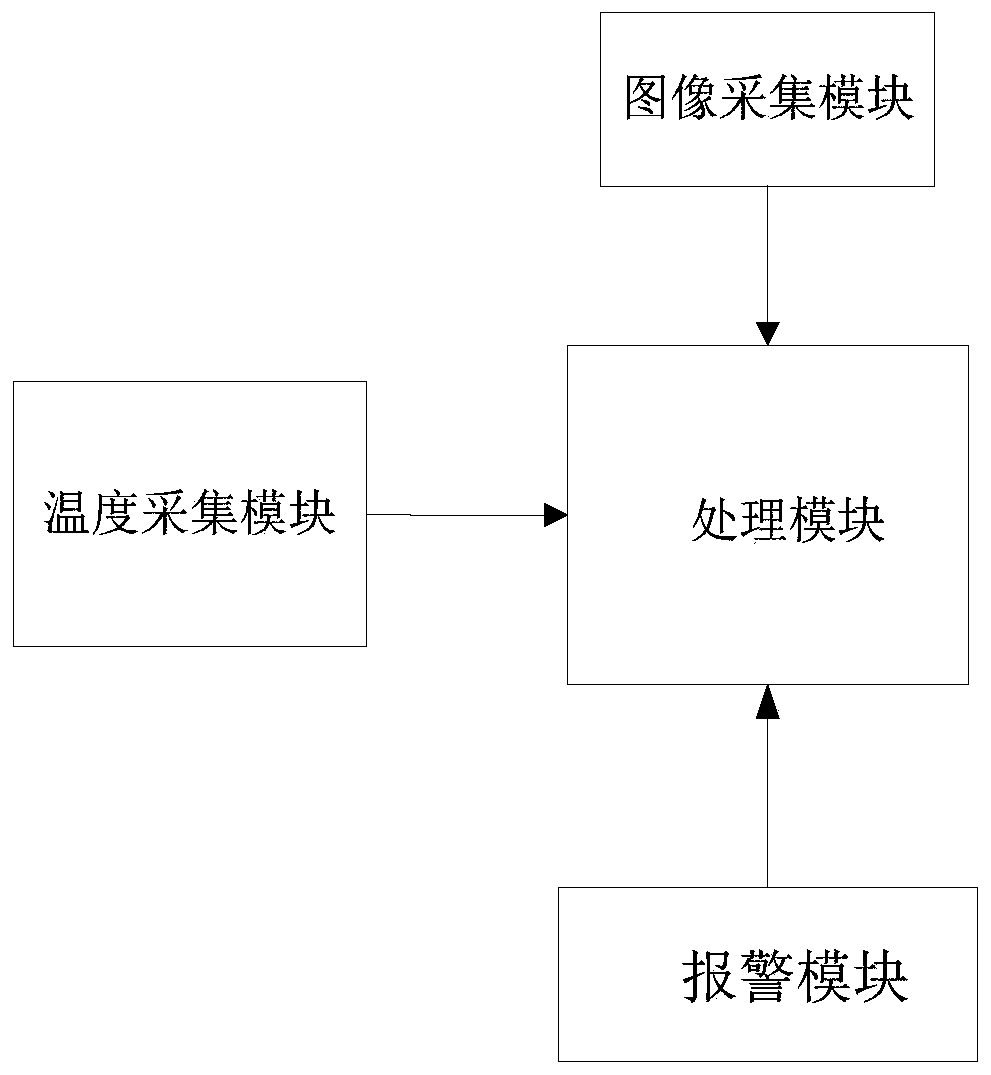

[0101] Based on Embodiment 1, this example provides an intelligent anti-dry heating system, the principle diagram of which is as follows figure 2 As shown, it includes image acquisition module, temperature acquisition module and processing module.

[0102] The image acquisition module is used to collect the state images of the cooking utensils during the cooking process. The image acquisition module includes a camera and a supplementary light assembly. The camera and the supplementary light assembly are installed on the hood or the integrated stove or other positions. The cooking utensils are observed, and the resolution is subject to the clear image of the object.

[0103] The temperature acquisition module is used to obtain the temperature information of the cooking utensils during the cooking process. The temperature acquisition module can use but not limited to multi-point or single-point infrared temperature sensors. The temperature acquisition module can be installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com