Optical scanning module and manufacturing method thereof

An optical scanning and module technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as poor response speed and poor heat dissipation performance, improve service life, improve heat dissipation performance, and overcome excessive welding lead resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

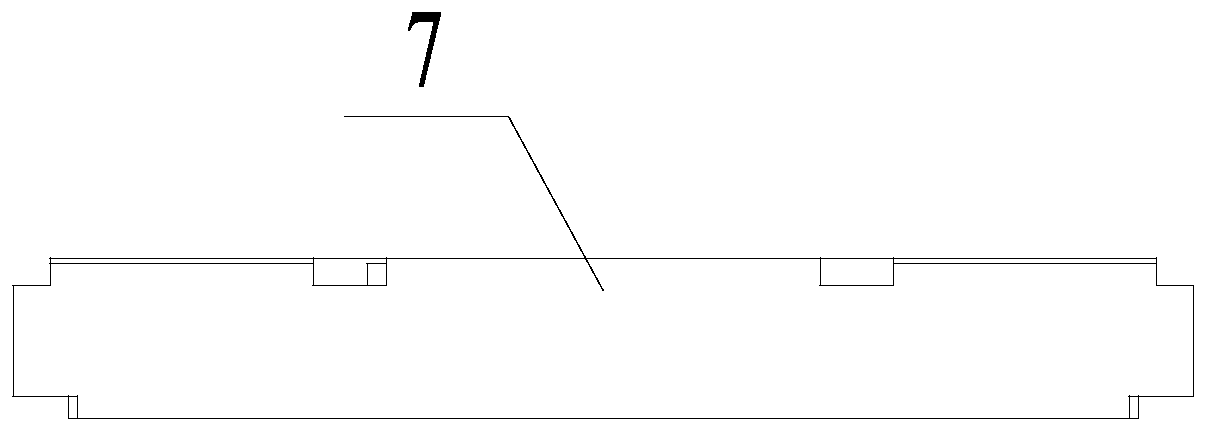

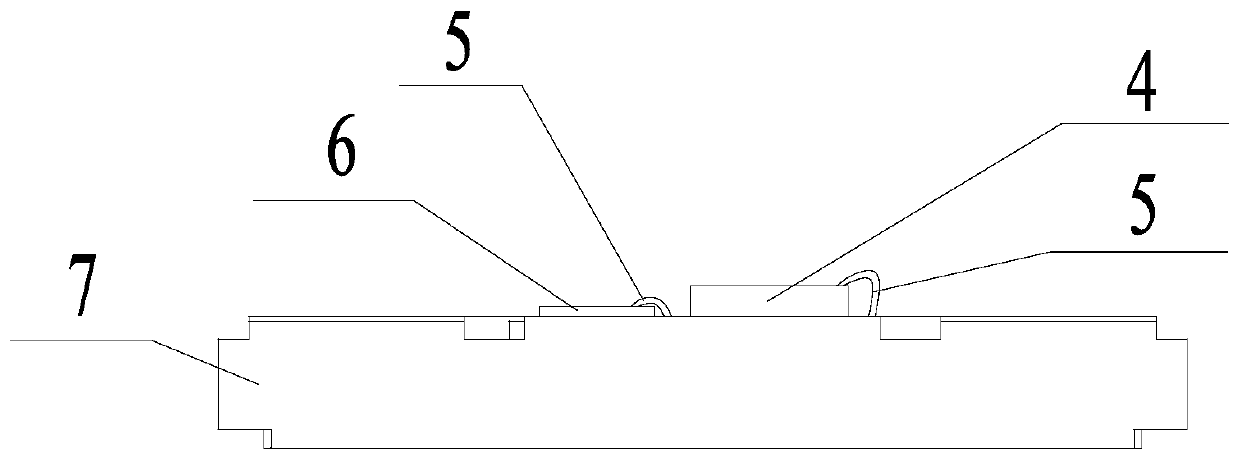

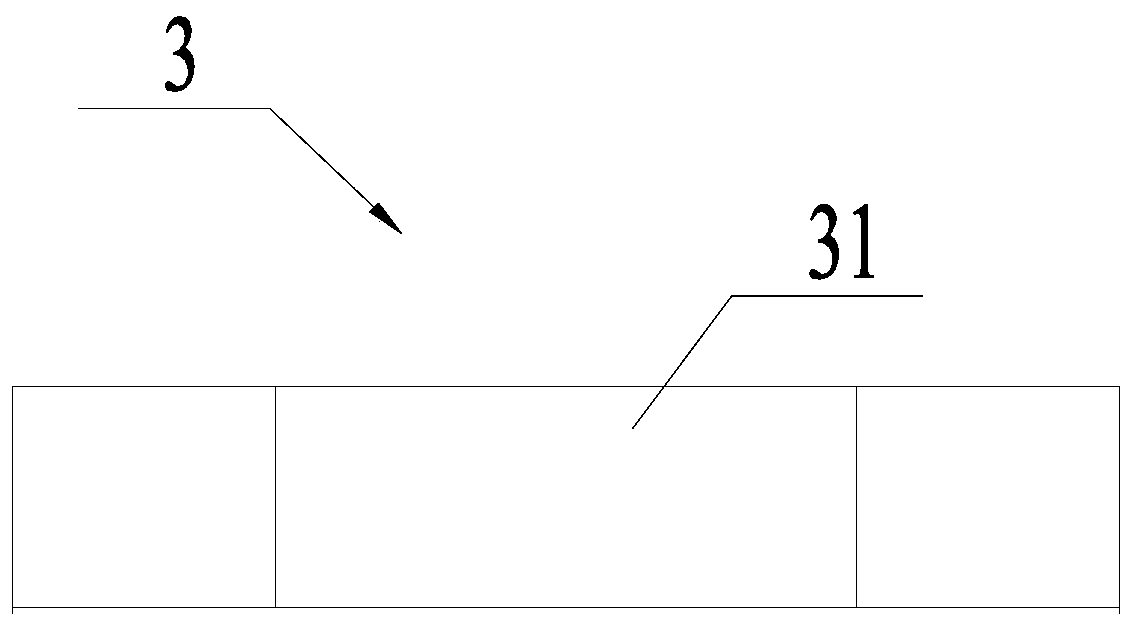

[0035] Please refer to Figure 6 to Figure 15, the optical scanning module 100 provided by the embodiment of the present invention includes an optical sensor 140, an electronic component 160, a heat sink substrate 110, a heat conduction bracket 120, and an optical lens 130 sequentially connected from bottom to top, and the lower plane of the heat conduction bracket 120 A groove 121 is arranged upward, and a light-transmitting groove 122 is also arranged on the heat sink substrate 110 . The upper plane of the groove 121, the optical sensor 140 is also in contact with the heat sink substrate 110 through the heat conduction medium layer 170, the electronic components 160 are arranged on the heat sink substrate 110, and the electronic components 160 is located in the orthographic projection area of the groove 121 and staggered distribution with the light sensor 140, the pad of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com