Welding device and welding method for rotating shaft and end plate of rolling barrel pepper stem cutting machine

A welding device and end plate technology, which is applied in the direction of tin feeding device, auxiliary device, welding equipment, etc., can solve the problems of unsmooth discharge, pepper residue, unclean cutting, etc., and achieve the effect of reducing coaxiality error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

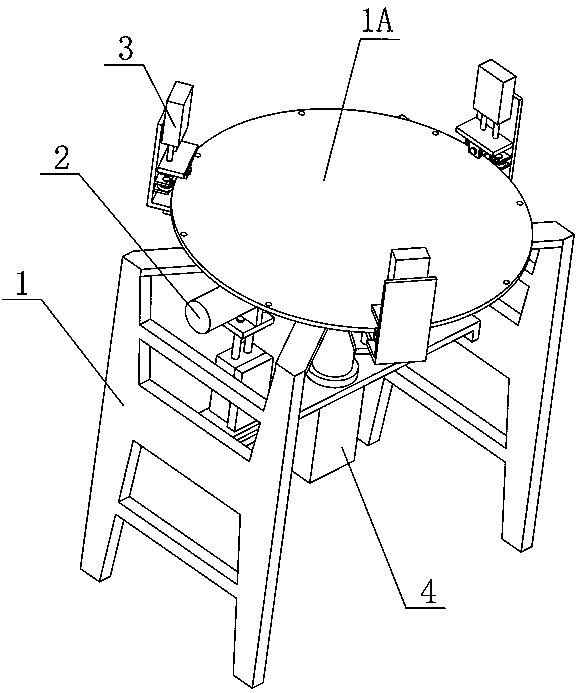

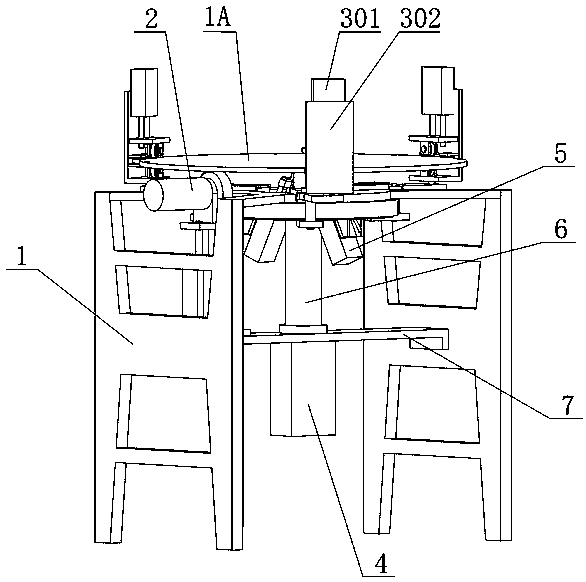

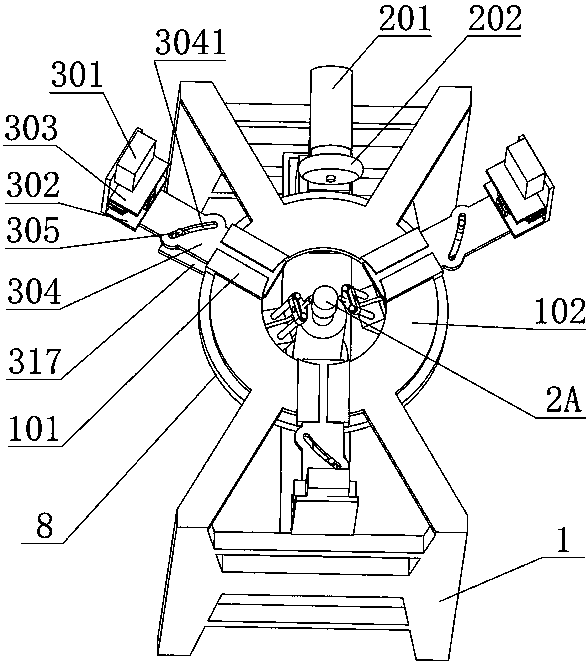

[0047] combine Figure 1-9 , the welding device of a kind of capsicum cutting machine rotating shaft and end plate of the present invention, comprises base frame 1, rotating driving mechanism 2, end plate centering mechanism 3, rotating shaft pressing cylinder 4, annular welding mechanism 5, rotating shaft sleeve 6, The support beam 7 and the electric turntable 8 are defined as the inner side toward the center of the end plate 1A, and the outer side if they are opposite, so as to describe the present application. The rotating drive mechanism 2 includes a servo motor 201, a driving wheel 202, a lifting cylinder 203, a cylinder seat 204, and a motor frame 205, and the described end plate centering mechanism 3 includes a pressing cylinder 301, a centering frame 302, and a lifting plate 303, slide plate 304, column pin 305, connecting shaft 306, square key 307, lower bearing 308, side shaft 309, side support seat 310, side bearing 311, upper bearing 312, upper shaft 313, upper sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com