A mixed box robot intelligent depalletizing system and control method

A technology of robot intelligence and control method, applied in the field of warehousing and logistics palletizing and depalletizing, which can solve the problems of low cost, difficult palletizing and depalletizing operations of mixed boxes, and small footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

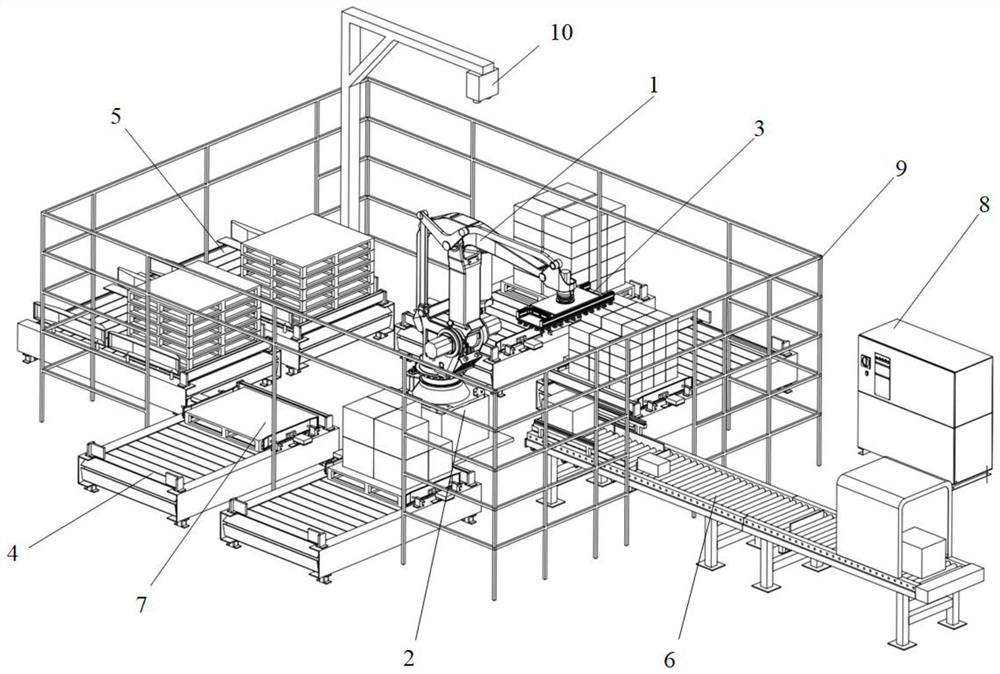

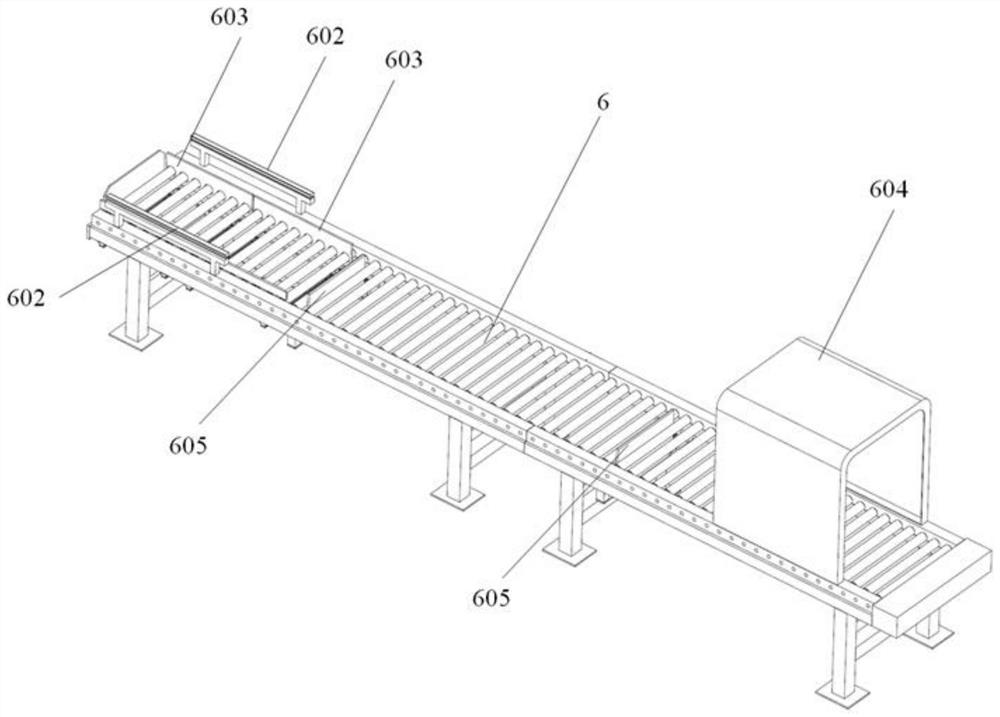

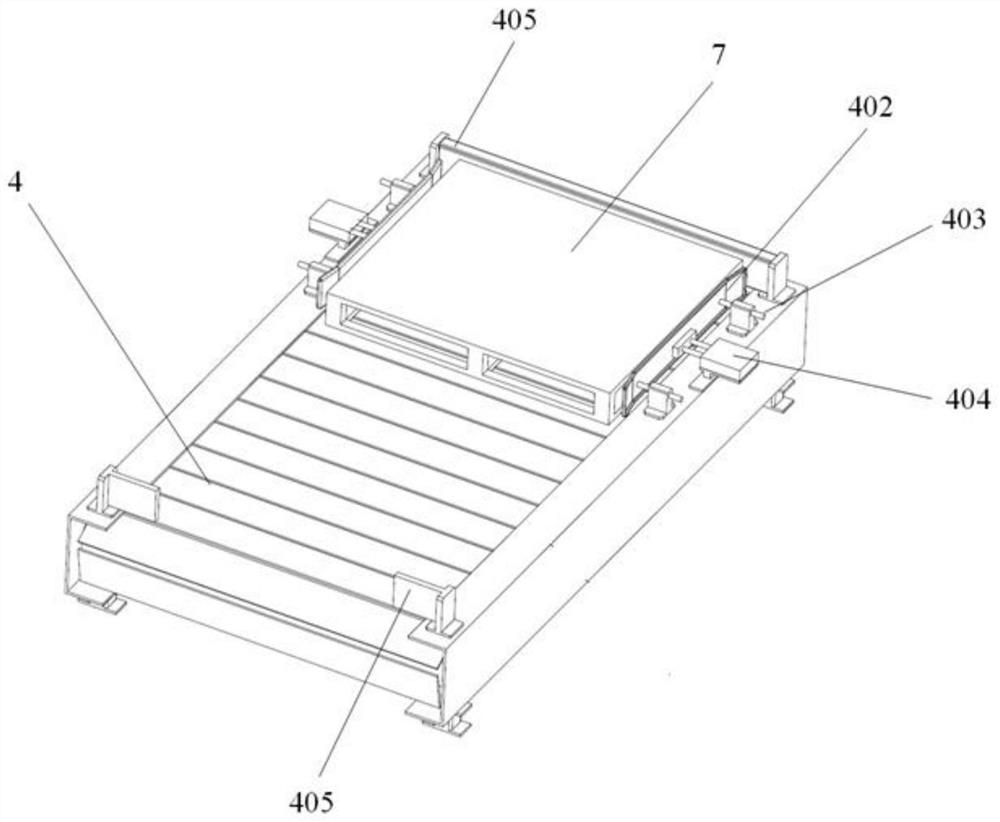

[0093] Such as figure 1 As shown, a kind of hybrid box robot intelligent depalletizing system described in the present invention comprises: a palletizing robot body 1, a palletizing robot base 2 installed at the bottom of the palletizing robot body 1, a palletizing robot body 1 installed on the palletizing robot body 1 The end picker 3 at the picking end, the pallet conveyor 4 installed on both sides of the palletizing robot body 1, the pallet conveyor 5 installed behind the palletizing robot body 1, and the roller conveyor installed in front of the palletizing robot body 1 6. The pallet 7 placed on the stack conveyor 4 and the pallet conveyor 5, the electrical control cabinet used to control the normal operation of the robot, auxiliary equipment and sensors 8, used to provide safety protection for the operation range of the palletizing robot body 1 The fence 9, the electrical control cabinet 8 placed outside the fence 9, and the 3D camera 10 installed and fixed directly above...

Embodiment 2

[0104] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 lies in a control method for an intelligent depalletizing system of a hybrid box robot, including the system described in Embodiment 1 and an electrical control cabinet 8; the palletizing robot body 1, 3D MODBUS TCP / IP communication is adopted between the camera 10, the electrical control cabinet 8 and the identification device 604, and the electrical control cabinet 8 is used as the main station to read the data of the identification device and the 3D camera, and analyze the type, size and The size and three-dimensional coordinates of each layer of the depalletizing pallet control the conveyor and palletizing robot to perform the corresponding depalletizing action. The end picker is equipped with a laser ranging sensor, combined with 3D camera data, to accurately measure the height data of the box, and provide data for the grabbing height of the palletizing robot during depalletizing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com