Automatic Lightweight Wallboard Production Line

A lightweight wallboard and production line technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems of low compressive strength and low production efficiency, achieve small footprint, improve production efficiency, cutting End face neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

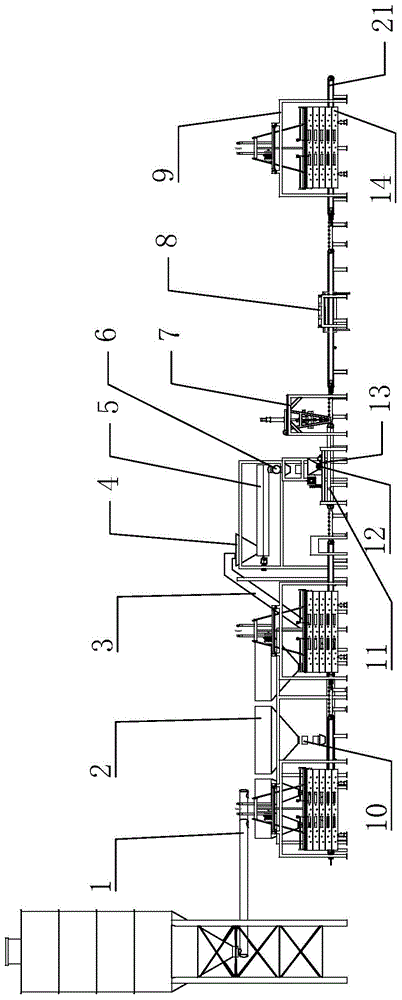

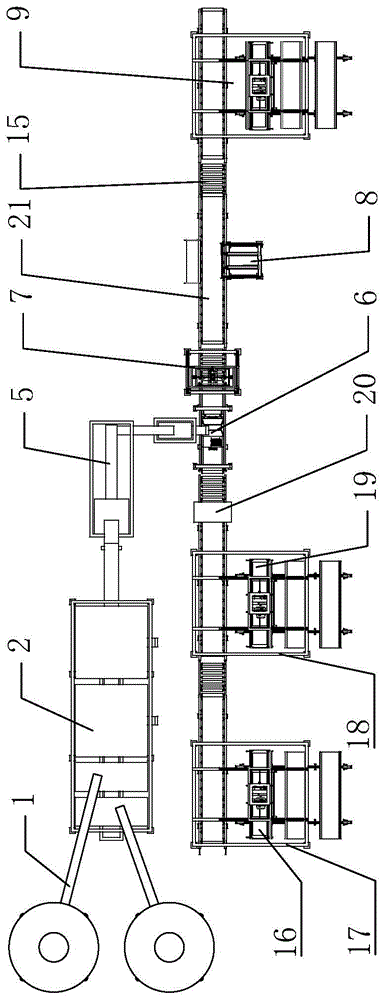

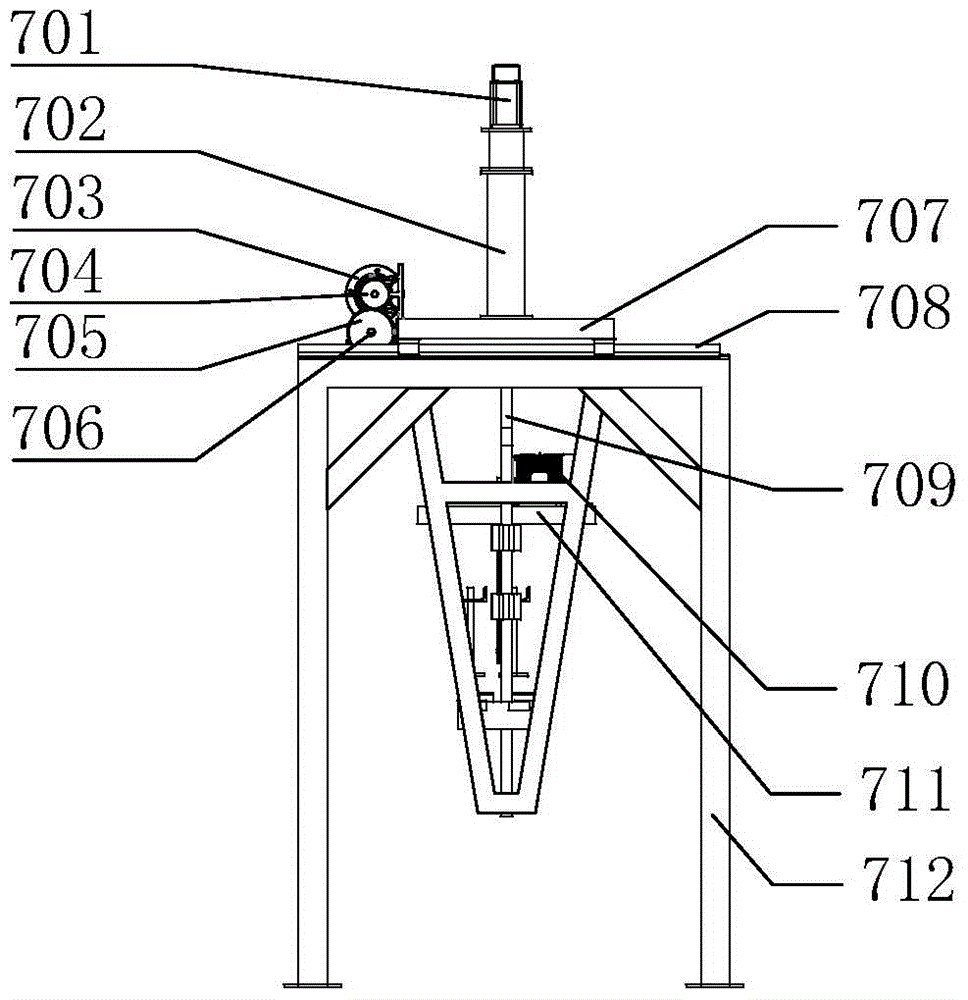

[0041] Such as figure 1 , figure 2 As shown, a fully automatic light wallboard production line includes a belt conveyor line 21 and a production line control system, and the production line control system controls the progress of the entire process. A mold 14 is placed on the belt conveying line 21, and the belt conveying line 21 is sequentially connected to the unstacking system, extrusion molding machine 13, cutting machine 7, waste rejecting machine 8, and palletizer 9, and the extrusion molding machine 13 is connected to the batching system , the batching system is connected to the raw material conveyor 1. A transition roller 15 is also provided in the middle of the belt conveying line 21 .

[0042] Described destacking system is arranged on the end of belt conveyor line 21, and belt conveyor line 21 side is provided with first conveyor 17 and second conveyor 18 successively, and first conveyor 17 and second conveyor 18 all select chain for use conveyor. The first conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com