Preparation method of sodium hyaluronate/sodium alginate injection type composite hydrogel

A technology of sodium hyaluronate and composite hydrogel, which is applied in the directions of non-active ingredients such as medical preparations, pharmaceutical formulas, prostheses, etc. The preparation method is simple and the application prospect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

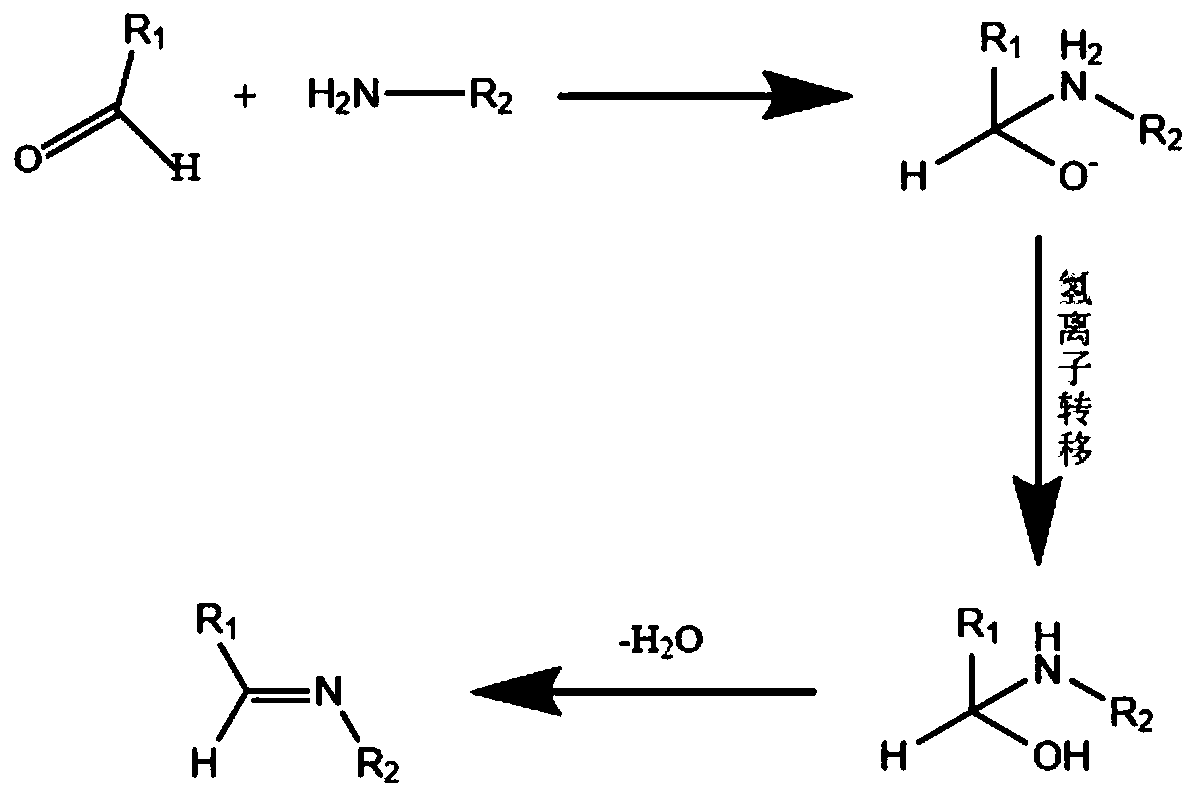

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of sodium hyaluronate / sodium alginate injection type composite hydrogel constructed by Schiff base cross-linking reaction, the specific steps are as follows:

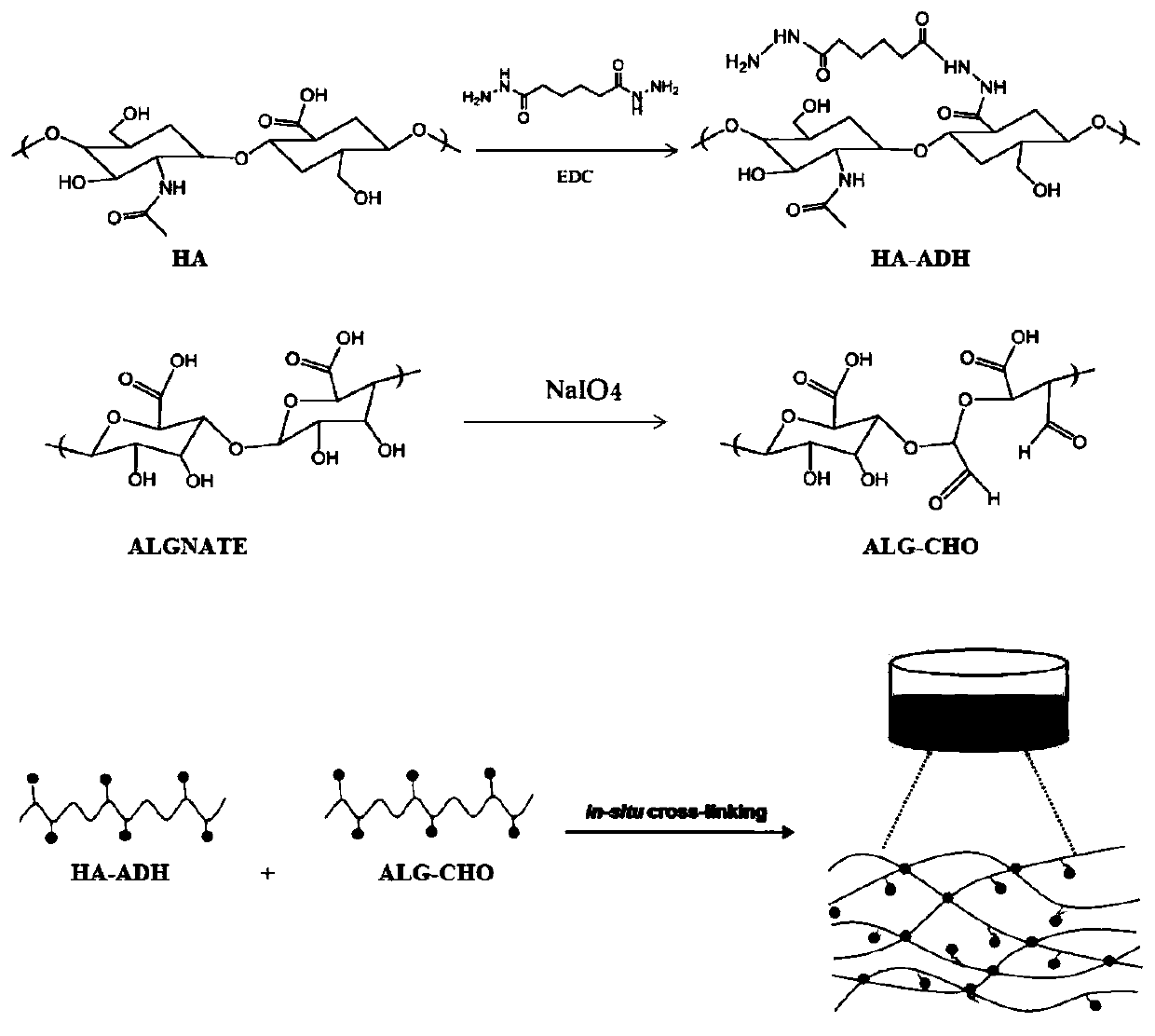

[0044] 1) Preparation of hyaluronic acid-adipic acid dihydrazide derivative (HA-ADH)

[0045] Put 2g HA (molecular weight 40KDa) solution in 400mL deionized water, then add 20g adipic acid dihydrazide and adjust the pH of the solution to 5.0-7.4 with hydrochloric acid, and further add 4.0g 1-ethyl-(3-dimethylaminopropyl) After carbodiimide (EDC), react overnight. Finally, the product HA-ADH solution is purified by dialysis (with a molecular weight cut-off of 8-10KDa dialysis bag) and then lyophilized for storage.

[0046] 2) Preparation of sodium alginate derivative (ALG-CHO)

[0047] Dissolve 2g of sodium alginate in 100ml of ultrapure water to form a 2% aqueous solution, and dissolve 1.1g of sodium periodate in 10ml of ultrapure water to form a solution; then add the sodium periodate solution to t...

Embodiment 2

[0051] A preparation method of sodium hyaluronate / sodium alginate injection type composite hydrogel constructed by Schiff base cross-linking reaction, the specific steps are as follows:

[0052] 1) Preparation of hyaluronic acid-adipic acid dihydrazide derivative (HA-ADH)

[0053] Put 2g HA (molecular weight 50 KDa) solution in 400mL deionized water, then add 30g adipic acid dihydrazide and adjust the pH of the solution to 5.0-7.4 with hydrochloric acid, and further add 6g 1-ethyl-(3-dimethylaminopropyl) After carbodiimide (EDC), react overnight. Finally, the product HA-ADH solution is purified by dialysis (with a molecular weight cut-off of 8-10KDa dialysis bag) and then lyophilized for storage.

[0054] 2) Preparation of sodium alginate derivative (ALG-CHO)

[0055] Dissolve 2g of sodium alginate in 200ml of ultrapure water to form a 1% aqueous solution, and take another 2g of sodium periodate dissolved in 20ml of ultrapure water to form a solution; then add the sodium periodate so...

Embodiment 3

[0059] A preparation method of sodium hyaluronate / sodium alginate injection type composite hydrogel constructed by Schiff base cross-linking reaction, the specific steps are as follows:

[0060] 1) Preparation of hyaluronic acid-adipic acid dihydrazide derivative (HA-ADH)

[0061] Put 4g HA (molecular weight 50KDa) solution in 400mL deionized water, then add 40g adipic acid dihydrazide and adjust the pH of the solution to 5.0-7.4 with hydrochloric acid, and further add 4.0g 1-ethyl-(3-dimethylaminopropyl) After carbodiimide (EDC), react overnight. Finally, the product HA-ADH solution is purified by dialysis (with a molecular weight cut-off of 8-10KDa dialysis bag) and then lyophilized for storage.

[0062] 2) Preparation of Sodium Alginate Derivatives (ALG-CHO) Take 2g of sodium alginate dissolved in 100ml of ultrapure water to form a 2% aqueous solution, and another 1.1g of sodium periodate dissolved in 10ml of ultrapure water to form Solution; Then add the sodium periodate soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com