Fabricated underground diaphragm wall

An underground diaphragm wall and prefabricated technology, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve the problems of water seepage, unreliable connection of underground soil, unreliable connection, etc., and achieve good operability and strengthen stable connection reliability, connection quality and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

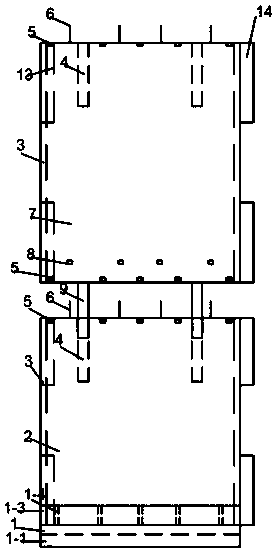

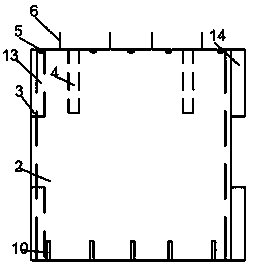

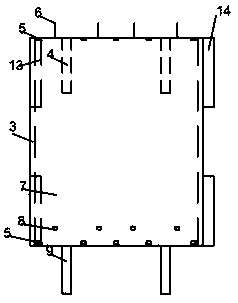

[0028] An assembled underground continuous wall, comprising a connection base 1, a bottom wall 2, a semicircular connection hole 3, a vertical circular connection hole 4, a U-shaped bolt installation port 5, a connection rib 6, a standard wall 7, and a connection rib installation Mouth 8, vertical connecting column 9, semicircular grouting hole A10, U-shaped bolt 11, nut 12, transverse connecting groove 13, the lower part of the connecting base 1 is provided with trapezoidal pouring groove 1-2, trapezoidal pouring groove The upper part of 1-2 is provided with a positioning plate 1-3, between the two positioning plates 1-3 is an installation groove 1-5, the size of the installation groove 1-5 is adapted to the bottom wall 2, and the inside of the positioning plate 1-3 is provided with a semicircle The semicircular grouting hole B1-4, the semicircular grouting hole 1-4 runs through the cap 1-6 and communicates with the trapezoidal pouring groove 1-2, and the lower part of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com