Wireless remote control refueling device

A technology of remote control and refueling device, applied in the input of lubricating oil, engine components, engine lubrication, etc., can solve the problems of low operation efficiency, waste of time, waste of human resources, etc., to improve operation efficiency, reduce operators, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

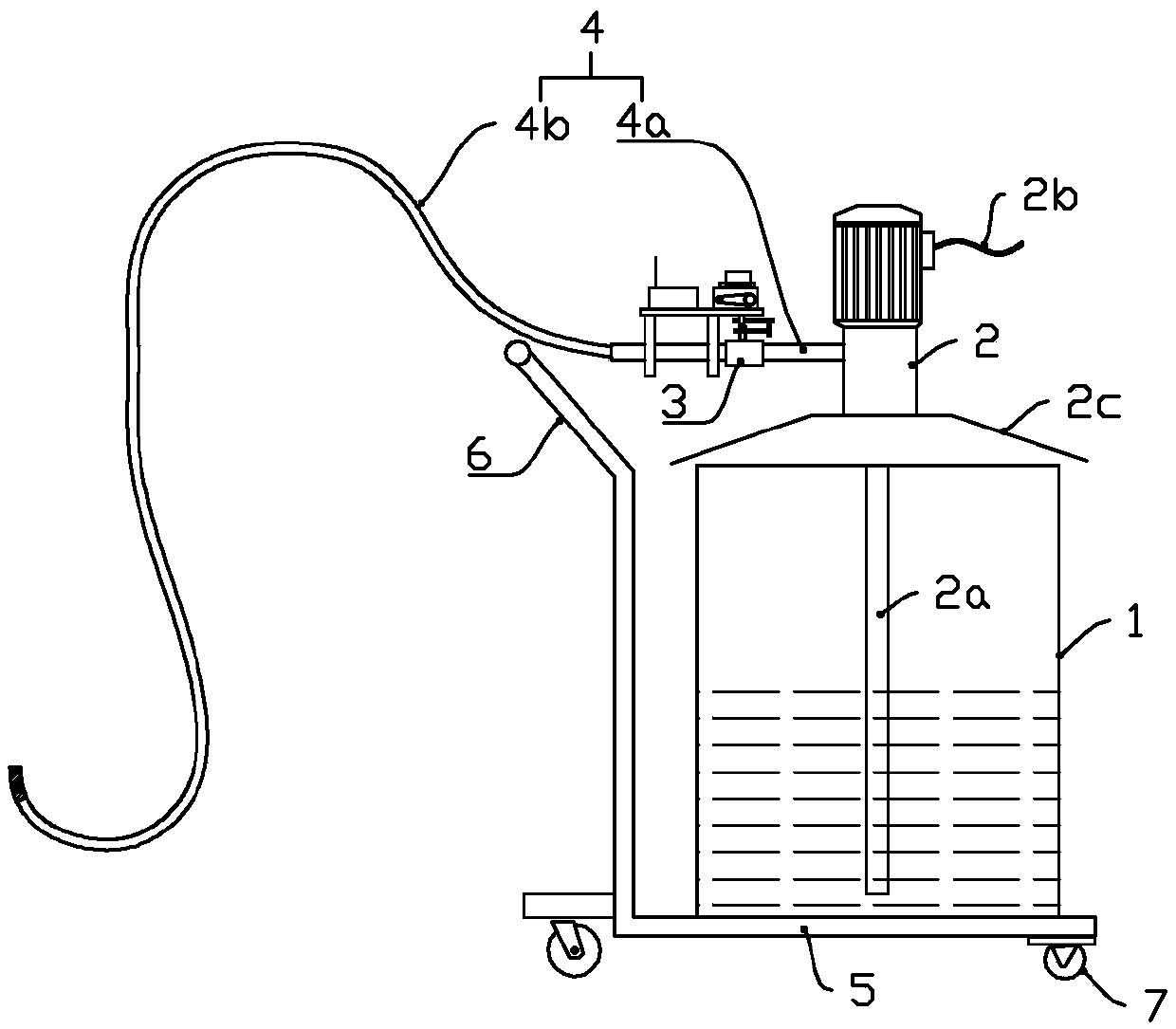

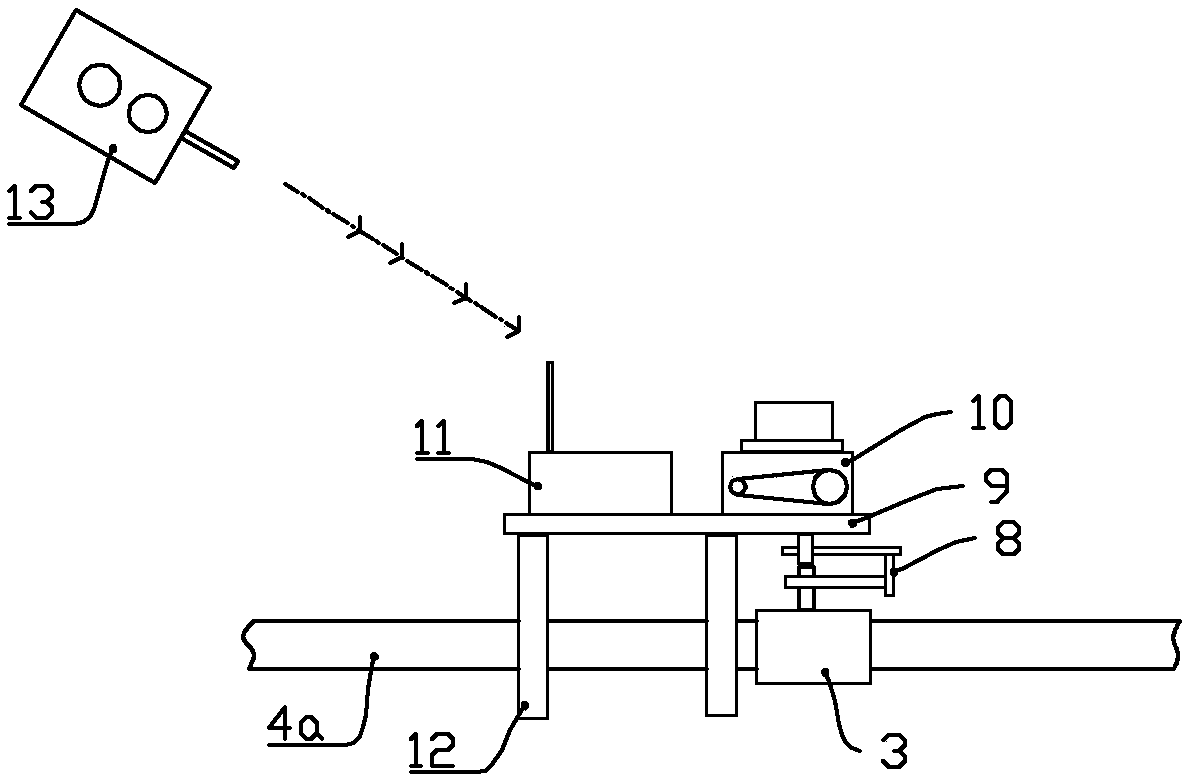

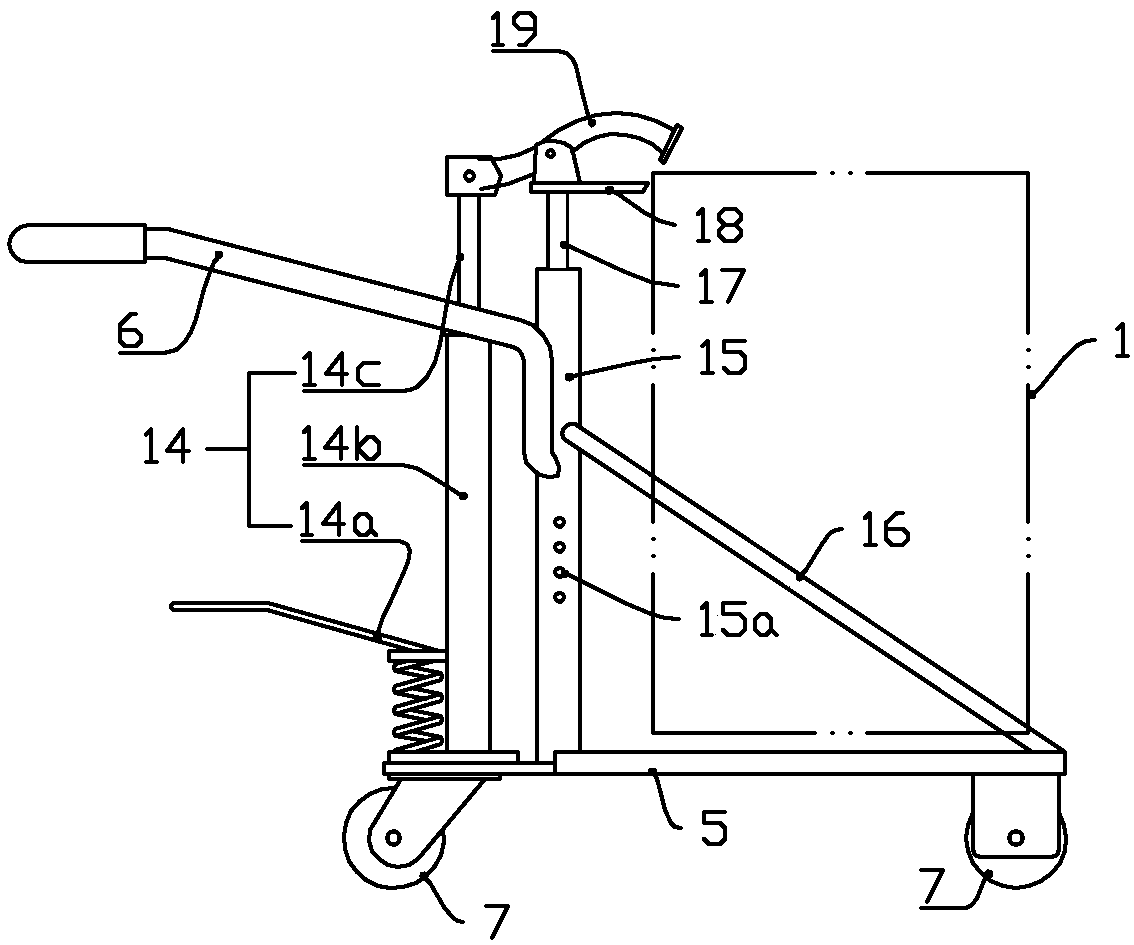

[0024] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-4 :

[0025] A wireless remote control refueling device, such as figure 1 As shown, it includes a movable platform, an oil tank 1, and an electric oil pump 2. The oil tank 1 is placed on the movable platform. The oil suction end 2a of the electric oil pump 2 is a long steel pipe structure, and an oil suction hole is set at the lower end of the steel pipe. The steel pipe extends into the oil tank 1 The motor part of the electric oil pump 2 is set above the oil tank 1 to facilitate the heat dissipation of the motor and the extraction of the power line 2b; for better dust prevention, a dustproof cover covering the opening of the oil tank 1 is provided. cover 2c, the dust cover 2c can be as figure 1 As shown, it is installed on the electric oil pump 2; setting the dust cover 2c on the electric oil pump 2 can also play a better supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com