Anti-explosion container with neck portion having good anti-explosion performance

A neck, good technology, applied in the field of anti-knock containers, can solve problems such as easy to bulge the neck, affect the structural strength and stability of the neck, achieve good structural strength, good anti-knock performance, and improve the effect of anti-knock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

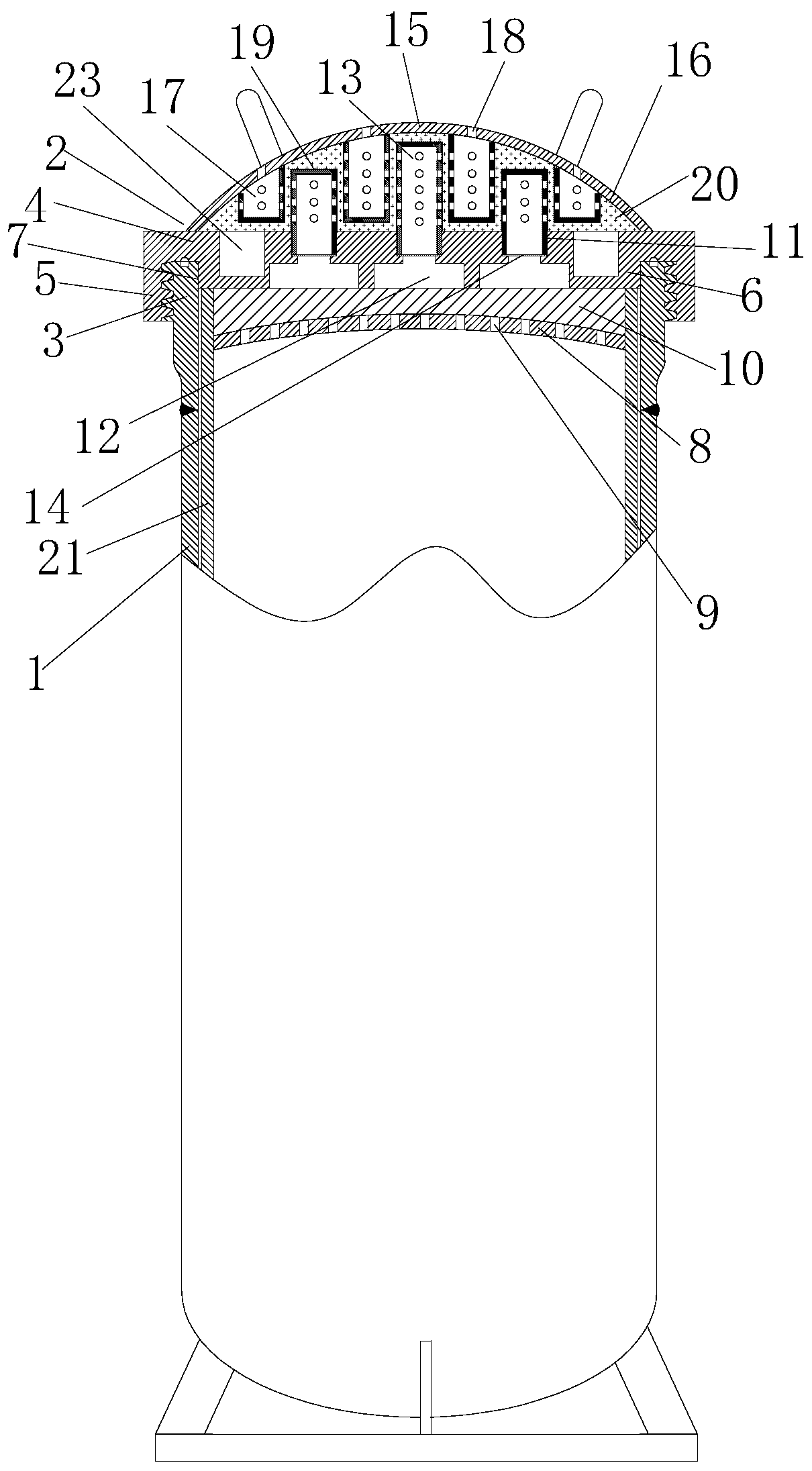

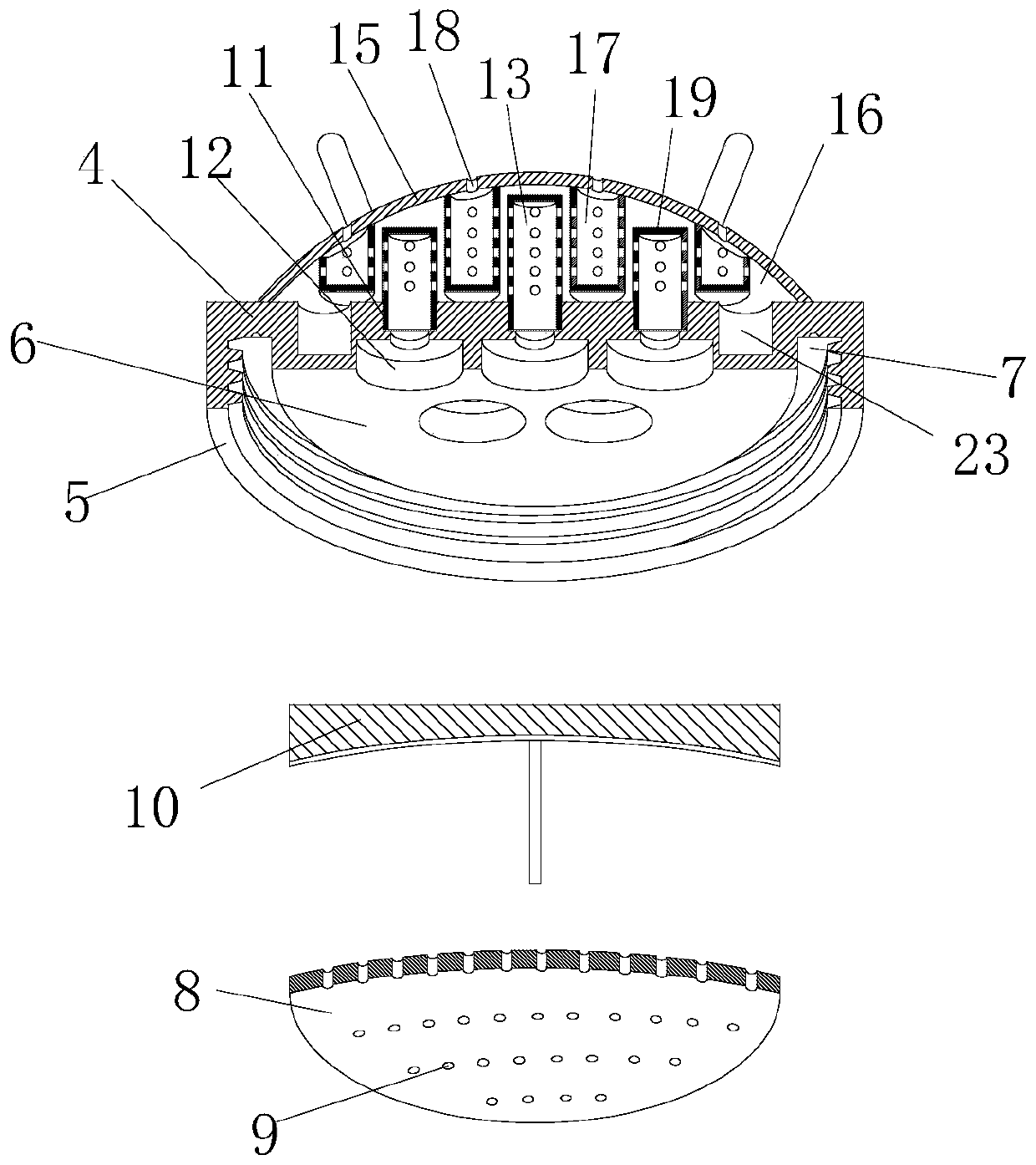

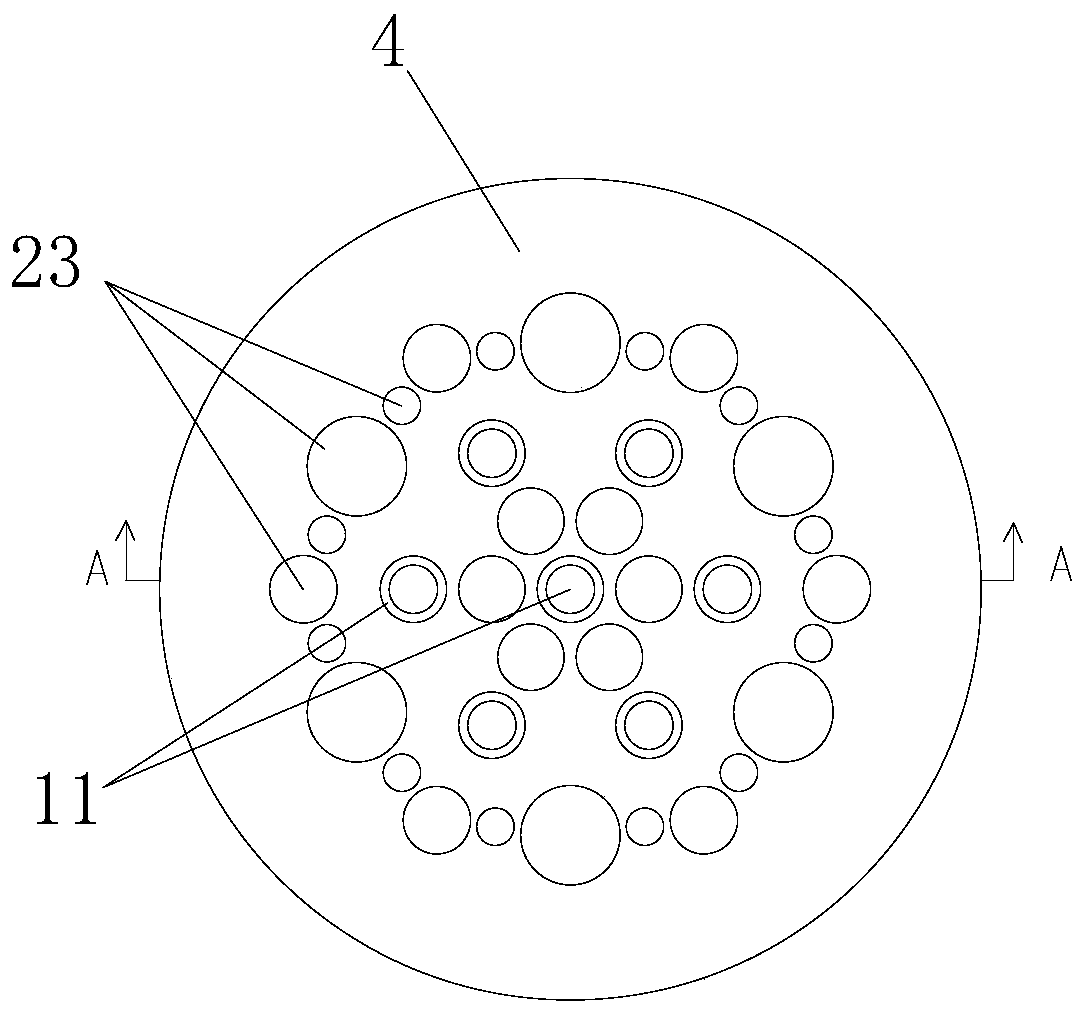

[0026] Such as Figure 1-6 As shown, an anti-knock container with good anti-knock performance at the neck includes a cylinder body 1 and a cover body 2. The opening position of the cylinder body 1 is fixedly connected with a neck 3 with a circular structure, and the cylinder body 1 and the neck body The part 3 is integrally formed, the cylinder 1 and the neck 3 are combined to form a straight cylindrical structure, the cover 2 and the neck 3 are detachably and fixedly connected, the cylinder 1, the cover 2, and the neck 3 Both are made of metal, the cover body 2 includes a cover plate 4, the lower end surface of the cover plate 4 is fixedly connected with a downwardly protruding snap ring 5 and a limit post 6, the limit post 6 is located inside the snap ring 5 and the position limit The centerline of the column 6 coincides with the centerline of the snap ring 5, and a limiting groove 7 for preventing the neck 3 from tilting is provided between the outer surface of the limiting...

Embodiment 2

[0031] Such as Figure 7 As shown, an anti-knock container with good anti-knock performance in the neck includes a cylinder body 1 and a cover body 2. The opening edge of the cylinder body 1 is folded toward the inside, and the opening position of the cylinder body 1 is fixedly connected with a circular structure The neck 3, the detachable and fixed connection between the cover 2 and the neck 3, the cylinder 1, the cover 2, and the neck 3 are all made of metal, the cover 2 includes a cover plate 4, The lower end surface of the cover plate 4 is fixedly connected with a downwardly protruding snap ring 5 and a stop post 6, the stop post 6 is located inside the snap ring 5 and the center line of the stop post 6 coincides with the center line of the snap ring 5, the Between the outer surface of the limiting column 6 and the inner surface of the snap ring 5, a limiting groove 7 for preventing the inclination of the neck 3 is provided, the upper end of the neck 3 is embedded in the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com