Camera interior orientation element calibration device and method based on array star points

A technology of internal orientation elements and calibration devices, applied to measuring devices, instruments, etc., to achieve the effects of saving production or purchase costs, eliminating influences, and improving calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

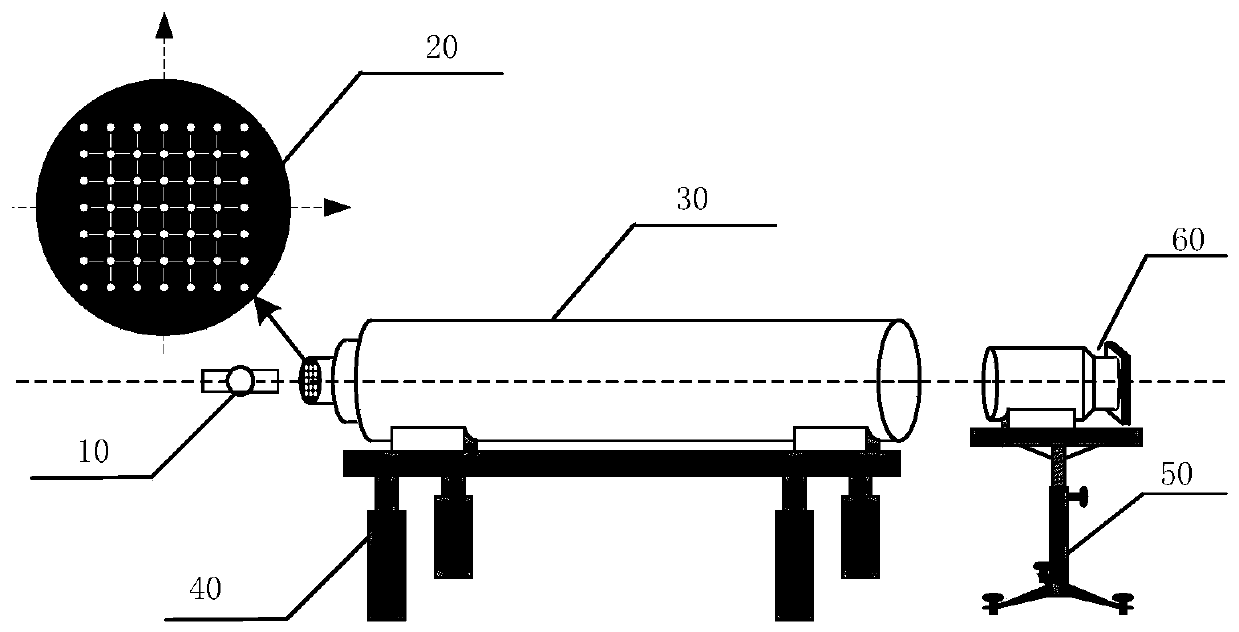

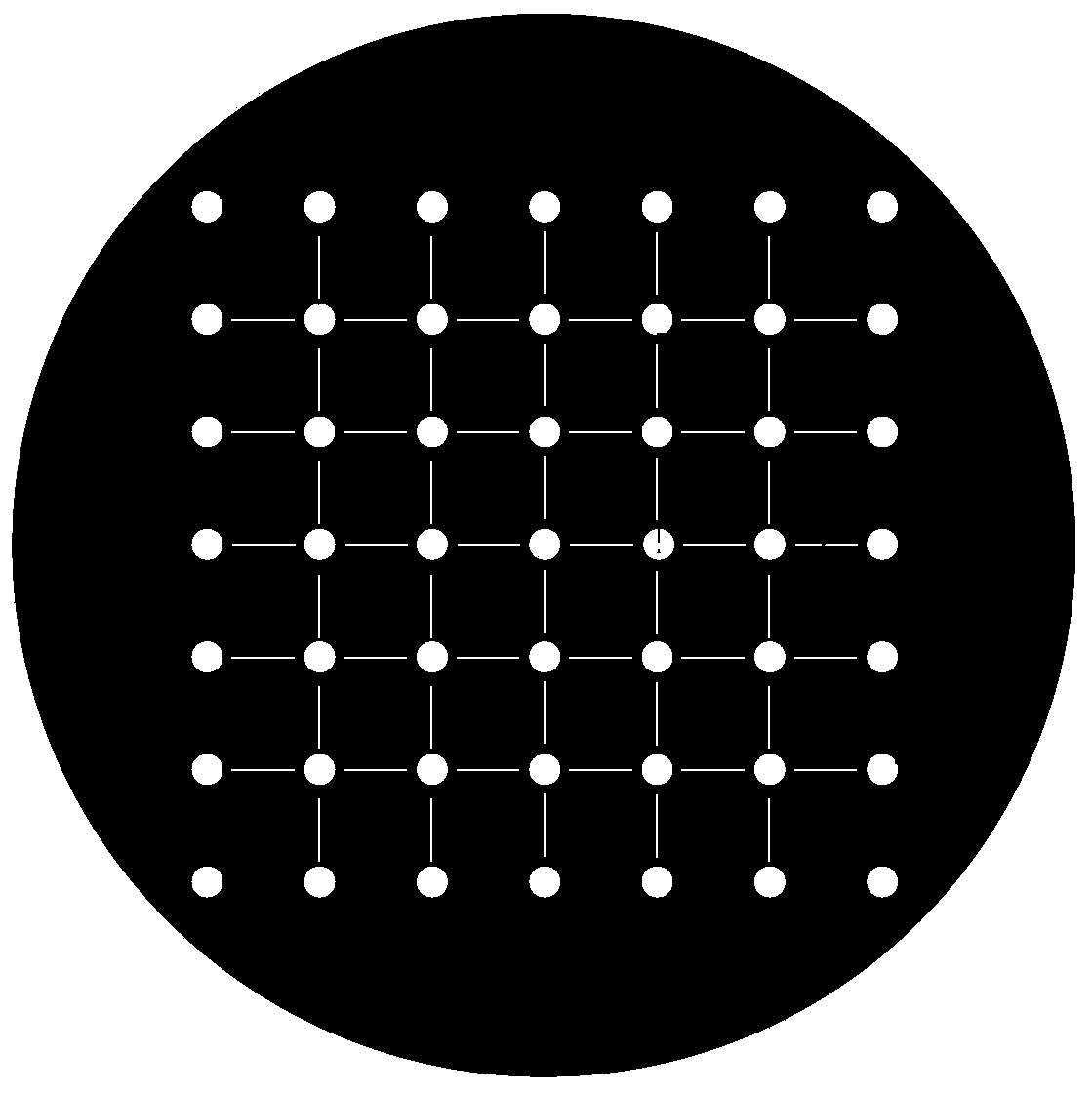

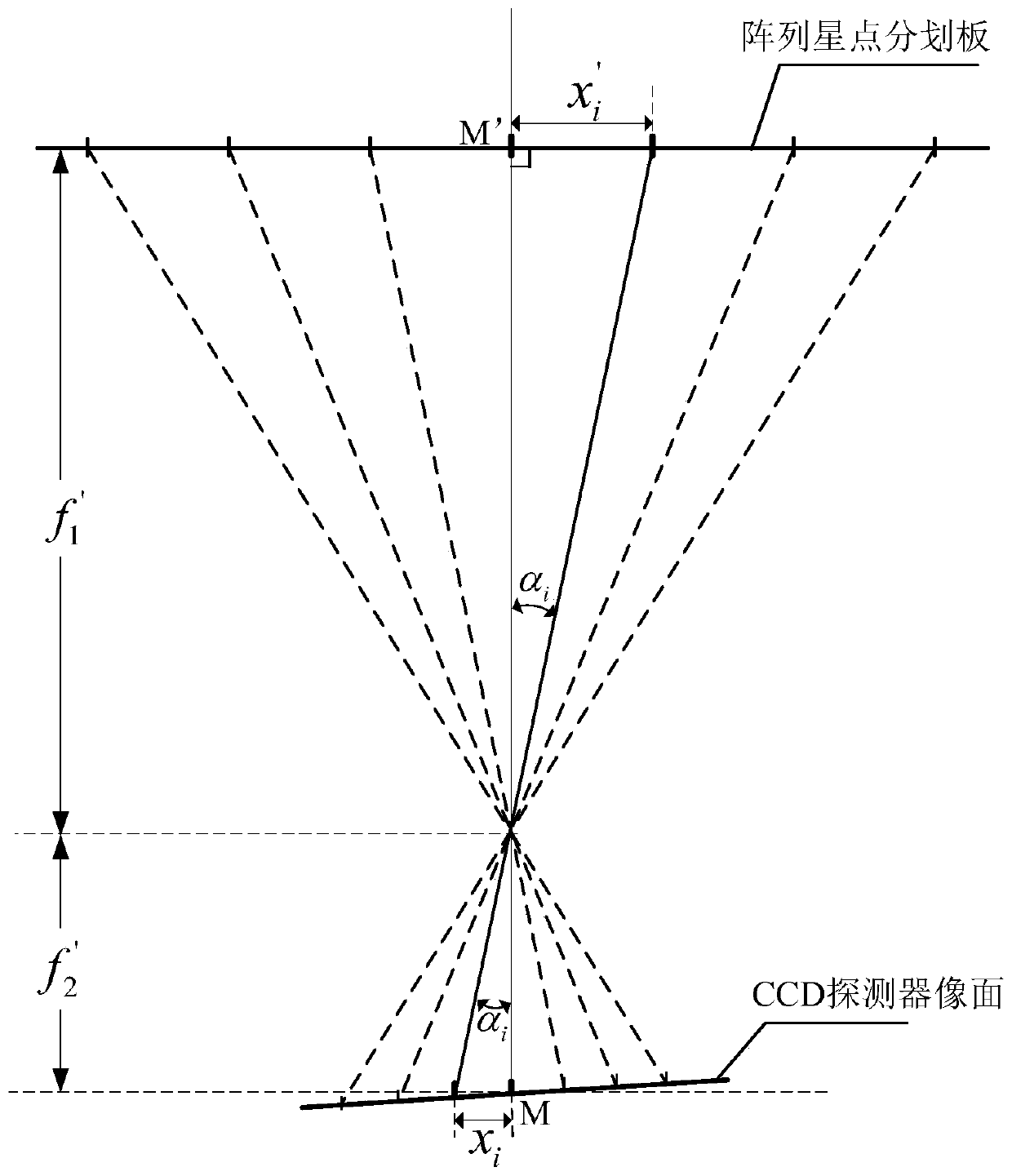

[0047] refer to figure 1 , the present invention is based on array star point calibration device for in-camera azimuth elements, comprising: light source 10, m×n array star point reticle 20, collimator 30, air flotation vibration isolation table 40, lifting workbench 50. Wherein, the m×n array star reticle 20 is used to form the m×n array star point image in the camera 60 to be marked by the collimator 30, and the array star point image formed by it is full of the field of view of the camera to be marked; The tube 30 is used to simulate the imaging of the camera to be marked to the infinite star point reticle target, and its focal length should be greater than the focal length of the camera 60 to be marked; Its influence: the elevating table 50 is used to sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com