High-thrust rim propeller and advancing tool adopting same

A thruster, high thrust technology, applied in the direction of rotary thrusters, propulsion components, ship propulsion, etc., can solve the problems of affecting the conversion efficiency of electric motors, unable to convert propulsion power, affecting the stability of the thruster, etc., to facilitate production and maintenance. , The effect of saving production and maintenance costs, and improving propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

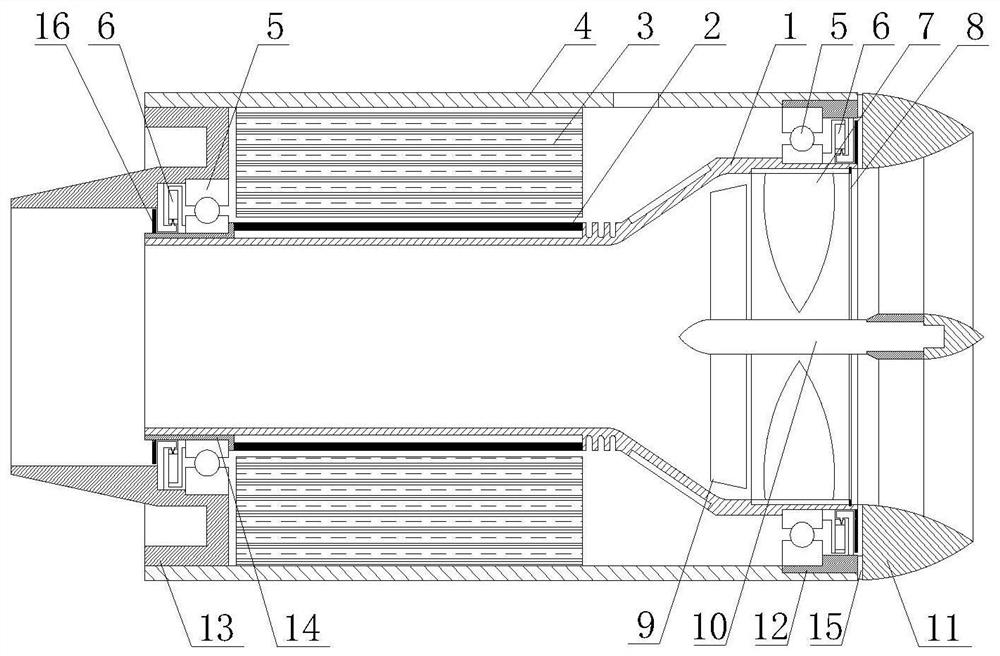

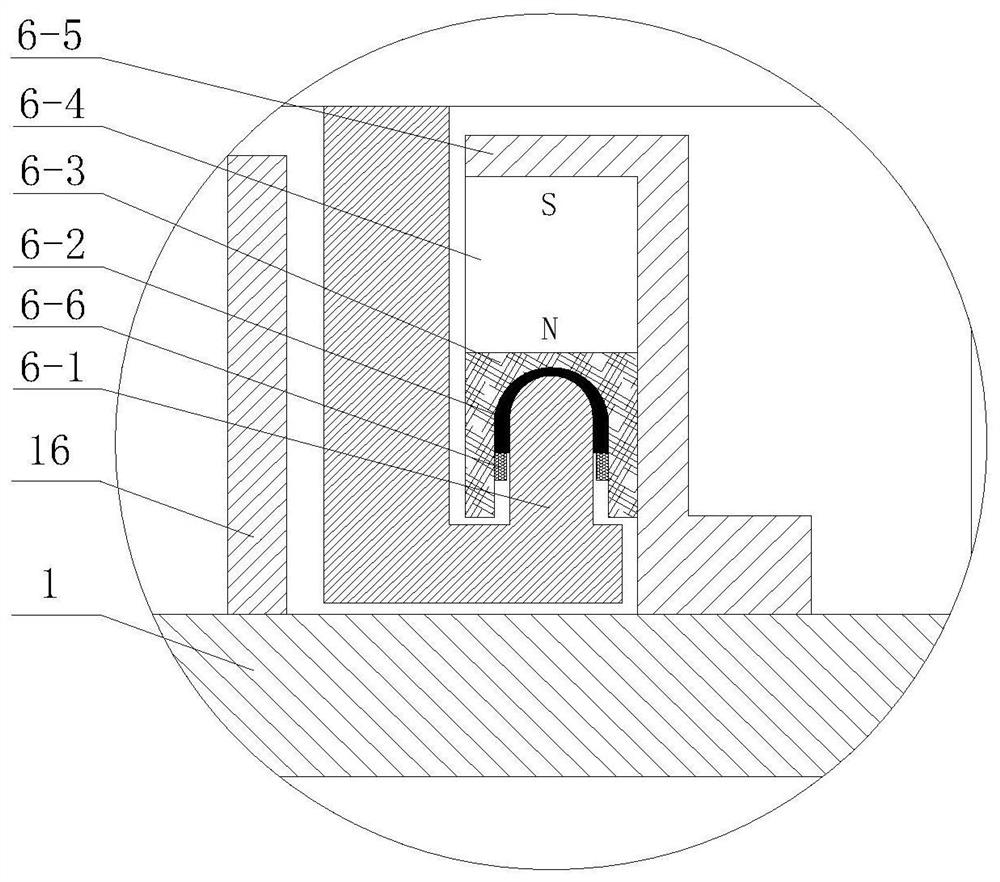

[0031] Such as Figure 1-8 As shown, a large-thrust rim propeller includes a rotating shaft 1, a housing 4, a motor stator 3 and a motor rotor 2. The rotating shaft 1 is hollow and horn-shaped, and the large end of the rotating shaft 1 is used for The propeller 7 is fixedly installed, and the small end is used for fixedly installing the motor rotor 2; the rotating shaft 1 is movably installed in the housing 4 through the bearing 5, the front end cover 12, the shaft sleeve 14 and the tail end cover 13; the motor stator 3 provides a rotating magnetic field for the motor rotor 2, drives the rotor 2 to drive the rotating shaft 1 to rotate; the sealing assembly 6 includes a concave pole 6-3 and a salient pole 6-1, and a permanent The magnet 6-4, the concave pole 6-3 is connected with the permanent magnet 6-4 and fixed on the rotating shaft 1 through the rotating ring 6-5, and the concave pole 6-3 is provided with a "U" groove, and the The concave pole 6-1 is poured from flexible m...

Embodiment 2

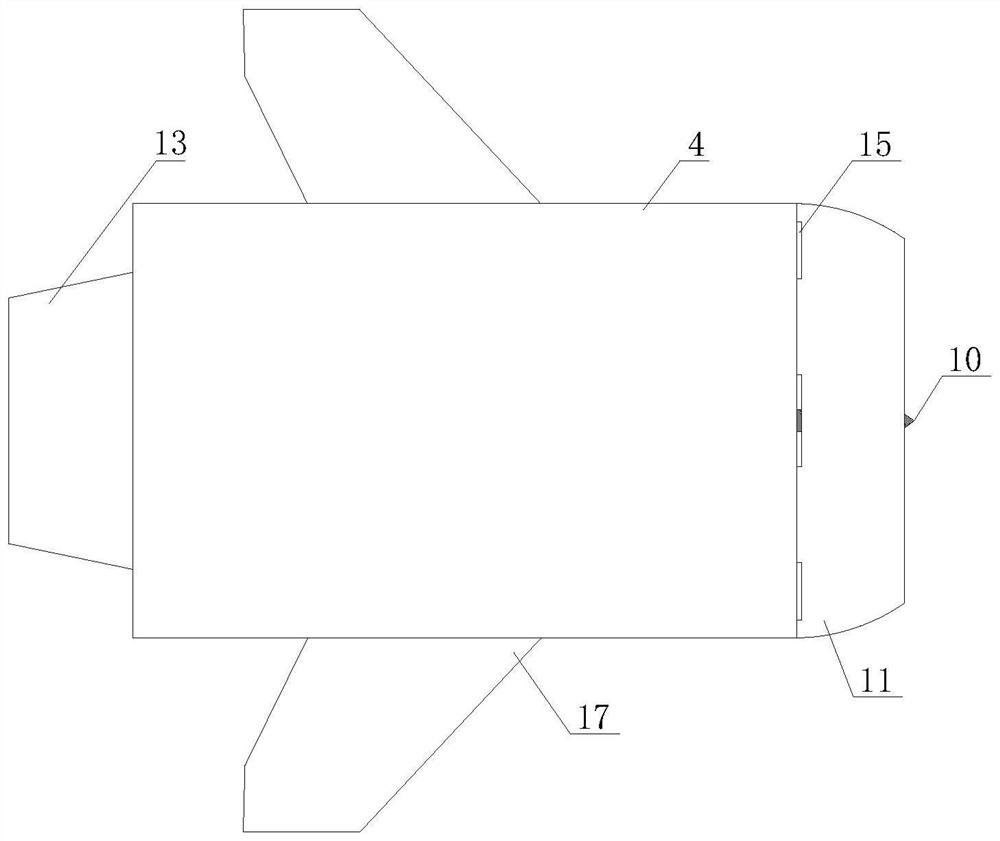

[0035] Such as Figure 9-10 As shown, a water traveling tool includes a body 19 and a propeller 18 for providing driving power for the body 19. The cross section of the tail of the body 19 is "W" shaped, and the "W" shaped cross section continues until it is close to the body. The position of the bow of 19 forms a straight-through flow channel in the longitudinal direction of the middle part of the body 19; the propeller 18 is any one of the above-mentioned rim propellers, and is installed in the stern flow channel of the body 19, which effectively reduces the occupation of the traditional propulsion system. The internal berth space of the main body 19 improves the space utilization rate; the said main body 19 is also equipped with a storage battery or a generator to provide electric power and the drive and controller of the motor part of the rim thruster. When the main body 19 travels in water, water can directly enter the rim propeller from the bow flow channel, avoiding the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com