Quality Inspection System Based on Multispectral Image Acquisition Technology

A multi-spectral image and quality detection technology, applied in the field of spectroscopy, can solve the problems of difficult internal quality detection, small quality feature area, and high detection cost, and achieve the effect of satisfying online detection requirements, enhancing quality feature area, and operating quickly and effectively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

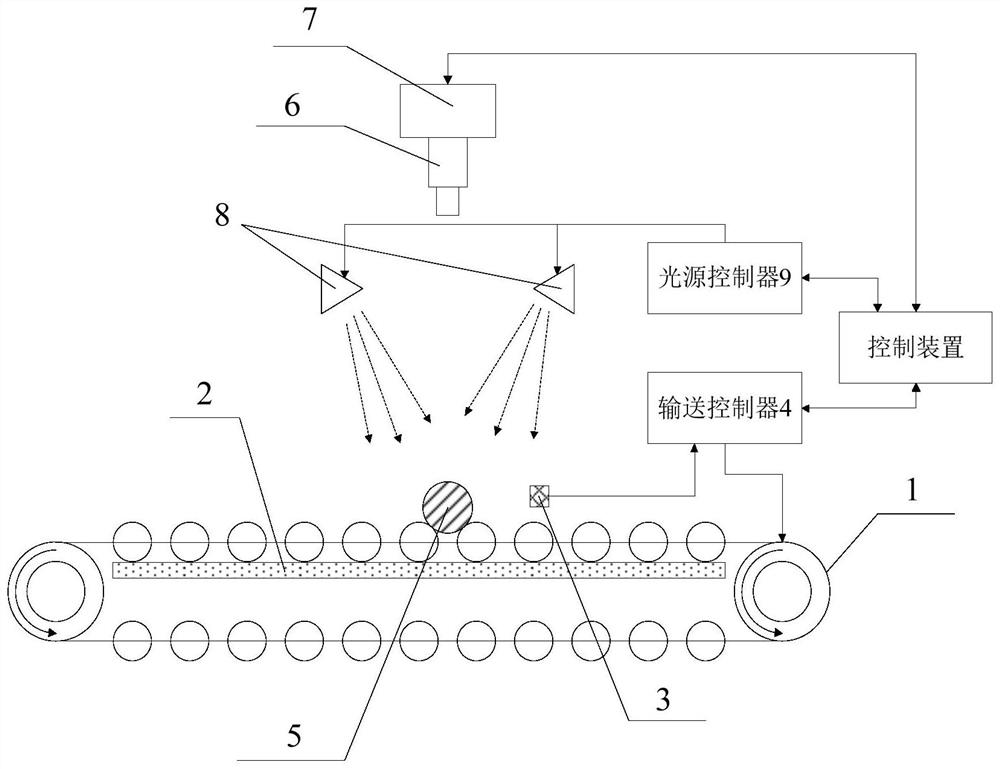

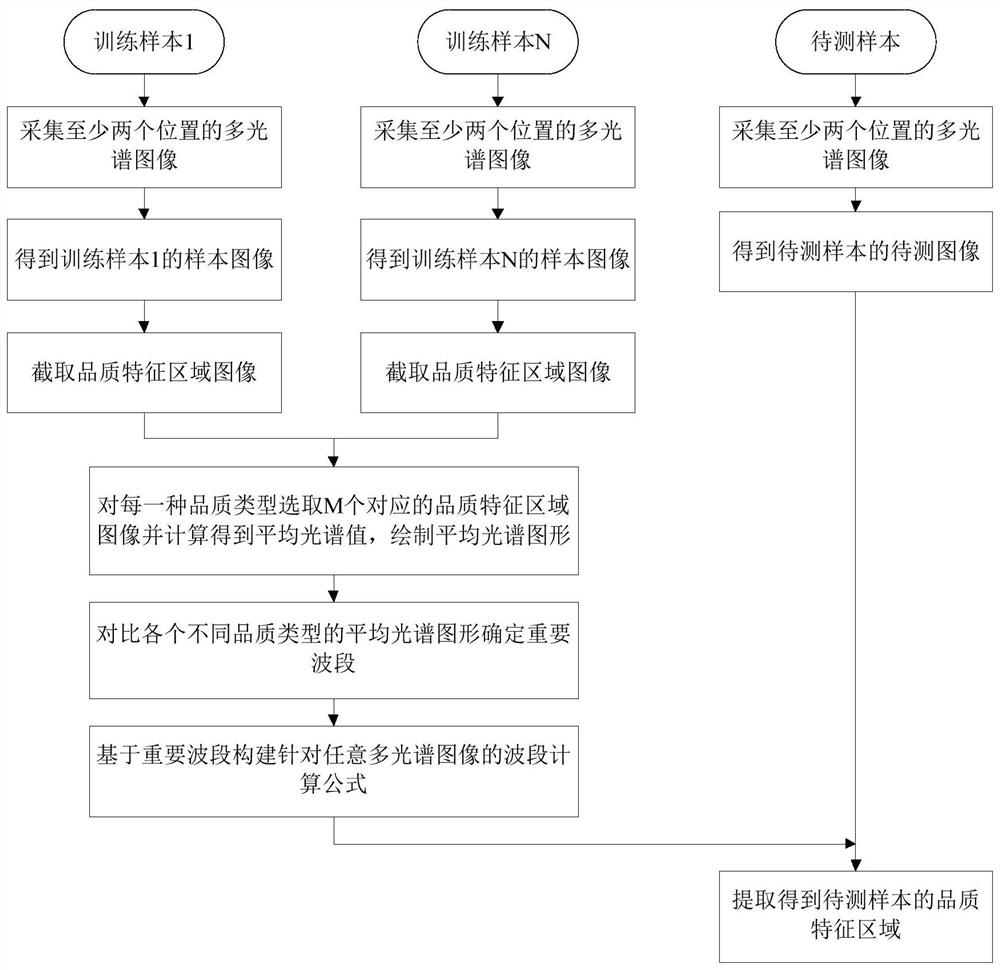

[0025] This application discloses a quality inspection system based on multi-spectral image acquisition technology, please refer to figure 1 , the quality inspection system mainly includes a conveying device, a multi-spectral image acquisition device and a control device. Wherein, the conveying device includes a roller conveyor 1, a friction plate 2, a displacement sensor 3 and a conveying controller 4, and the conveying controller 4 is connected to the roller conveyor 1, and the roller conveyor 1 includes at least two cylindrical rollers fixed side by side, two adjacent rollers The gap between the two cylindrical rollers is smaller than the size of sample 5. The roller conveyor 1 usually also includes a sprocket and a chain. The chain is sleeved on the sprocket and connected to the cylindrical roller. The conveying controller 4 controls th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com