Lithium battery preventing falling and failure and preparation method of lithium battery

A technology of lithium battery and manufacturing method, which is applied in the direction of electrolyte storage battery manufacturing, secondary battery, battery pack parts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

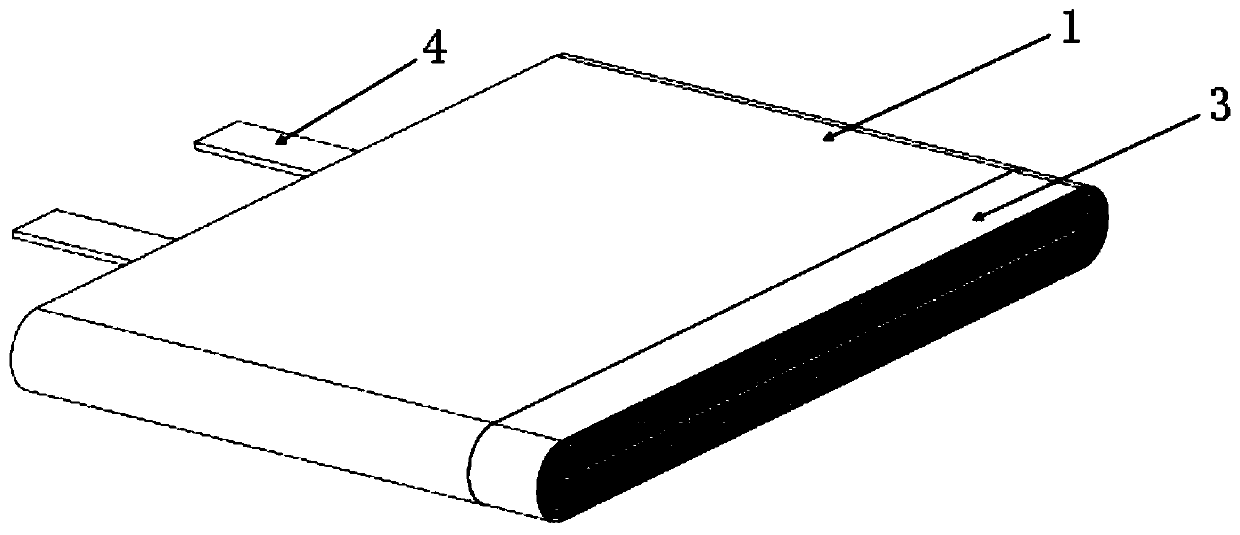

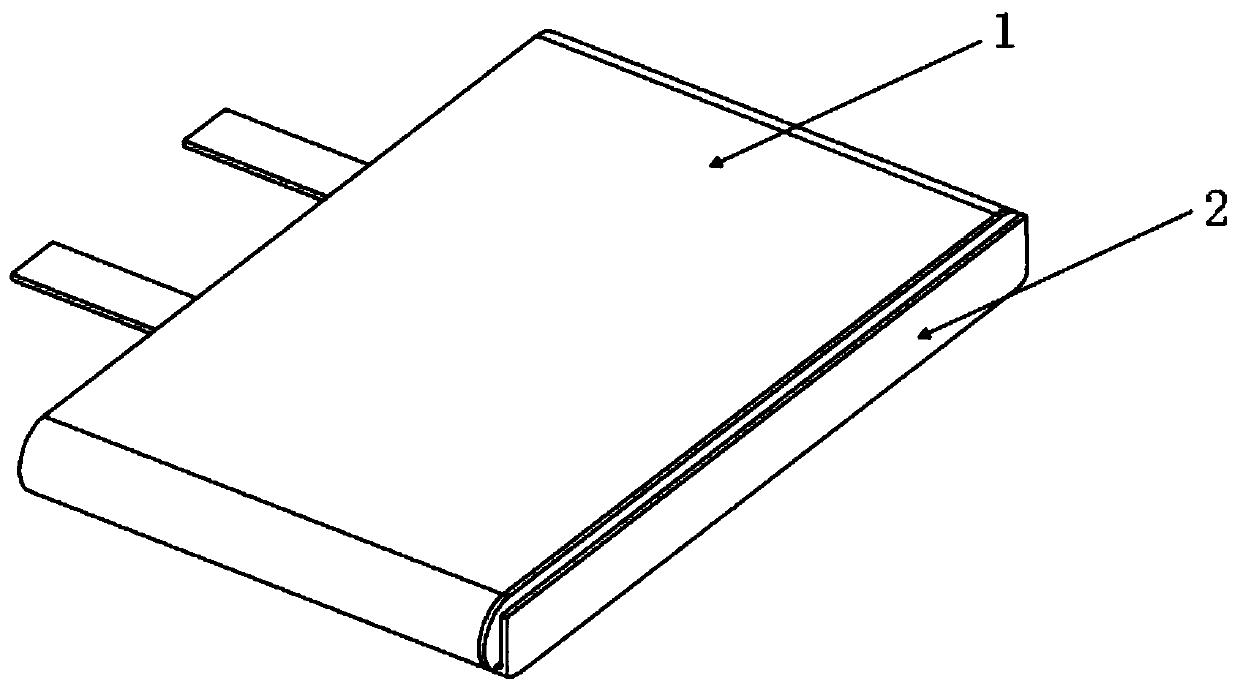

[0030] A lithium battery that prevents drop failure, including a battery membrane case and a cell placed in the battery membrane case, the battery cell includes a cell body 1 and a diaphragm stack 2, and the diaphragm stack 2 and the cell body 1 Integral connection and located at the tail of the cell body 1, the diaphragm stack 2 is a sheet structure formed by fusing several layers of diaphragms 12 extending in the length direction of the cell body 1, the diaphragm stack 2 Close to the cell body 1 and fold along the thickness direction of the cell body 1 .

[0031] Further, the diaphragm stack 2 is integrally connected with the lower surface of the cell body 1 and folded upwards.

[0032] Further, the width of the diaphragm stack 2 is equal to the thickness of the cell body 1 .

[0033] Further, the cell body 1 is a wound type cell.

specific Embodiment approach 2

[0035] The method for making a lithium battery that prevents drop failure described in the specific embodiment 1 includes the following steps:

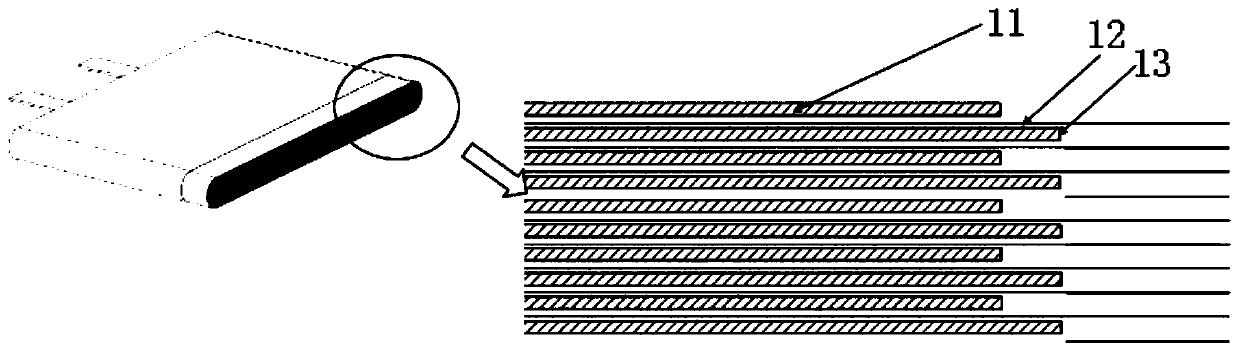

[0036] Step 1: Align and wind the positive electrode sheet 11, separator 12 and negative electrode sheet 13 to form a wound cell body 1, the width of the separator 12 is greater than the width of the positive electrode sheet 11 and the width of the negative electrode sheet 13, and the separator 12 is The part wider than the positive electrode sheet 11 and the negative electrode sheet 13 in width extends from the tail of the cell body 1 to form a separator fusion zone 3;

[0037] Step 2: The diaphragm in the diaphragm fusion region 3 is compacted along the thickness direction of the cell body 1 and fused together to form a diaphragm stack 2;

[0038] Step 3: Put the diaphragm stack 2 close to the cell body 1 and fold it along the thickness direction of the cell body 1, and then put it into the battery membrane case to form a lithium ba...

specific Embodiment approach 3

[0042] A lithium battery that prevents drop failure, including a battery membrane case and a cell placed in the battery membrane case, the battery cell includes a cell body 1 and a diaphragm stack 2, and the diaphragm stack 2 and the cell body 1 Integral connection and located at the tail of the cell body 1, the diaphragm stack 2 is a sheet structure formed by fusing several layers of diaphragms 12 extending in the length direction of the cell body 1, the diaphragm stack 2 Close to the cell body 1 and fold along the thickness direction of the cell body 1 .

[0043] Further, the diaphragm stack 2 is integrally connected with the lower surface of the cell body 1 and folded upwards.

[0044] Further, the width of the diaphragm stack 2 is equal to the thickness of the cell body 1 .

[0045] Further, the cell body 1 is a laminated cell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com