Sample for welding crack sensitivity test and welding crack sensitivity test method

A welding crack and sensitivity technology, applied in the field of samples and tests, can solve the problems of poor, difficult to guarantee the accuracy and consistency of the gap distance between the inclined Y grooves, difficult to quantitatively evaluate and compare, and achieve test reproduction. Good performance and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

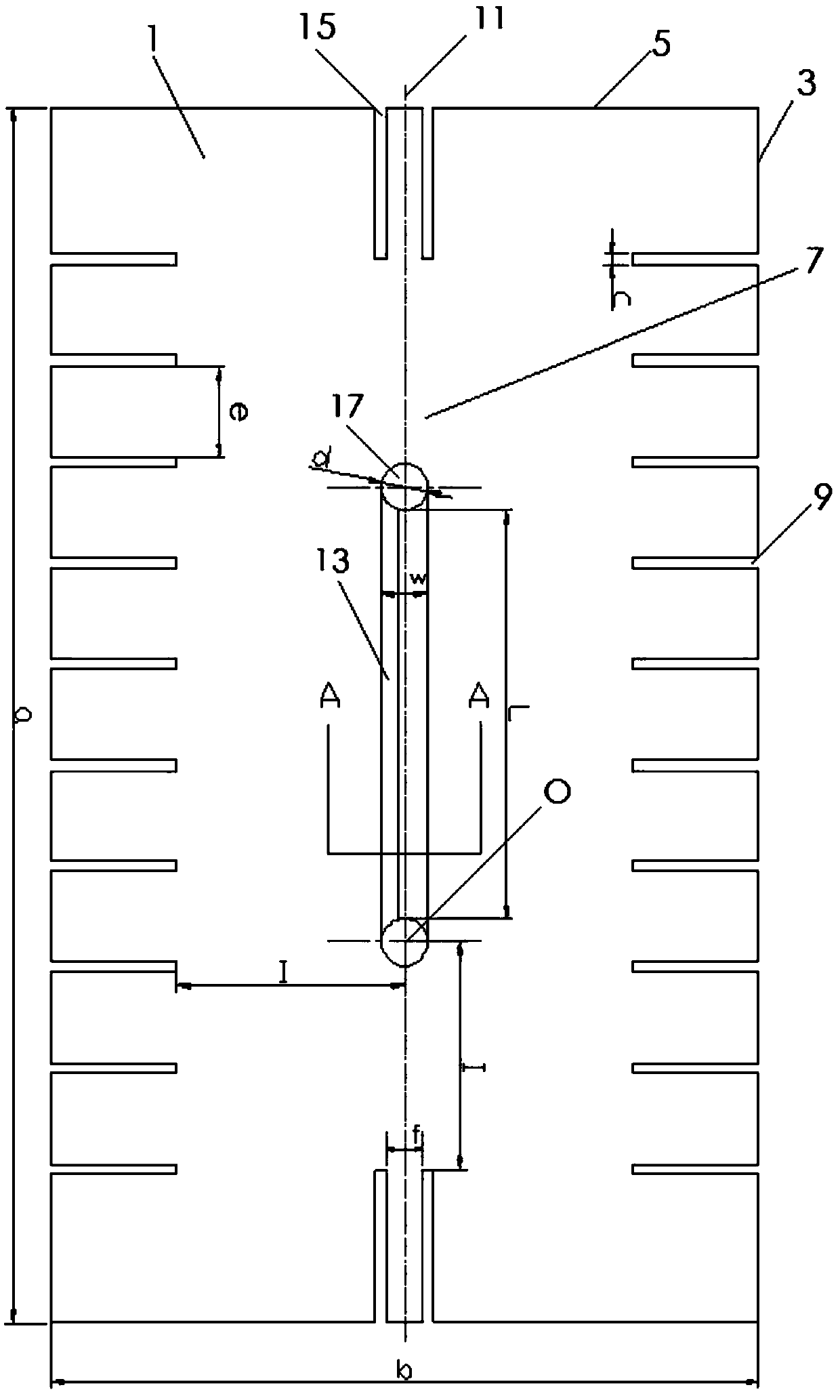

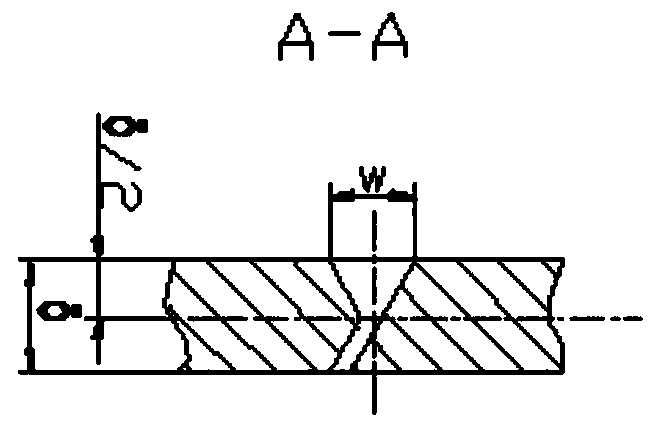

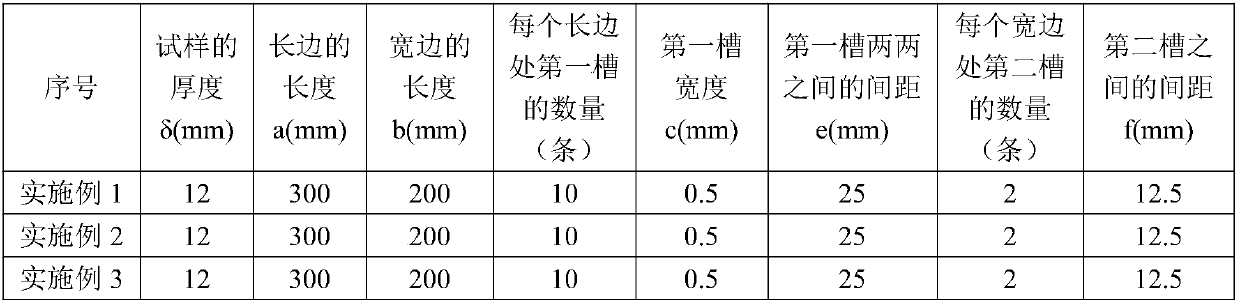

[0038] The sample that is used for welding crack sensitivity test of embodiment 1-8, its thickness and composition are all identical, and the material of sample is high-strength steel, and its structure is all according to figure 1 and figure 2 Set up as shown, and its specific structural parameters are listed in Table 1-1 and Table 1-2.

[0039] Table 1-1. Structural parameters of the samples used in the welding crack sensitivity test of embodiments 1-8

[0040]

[0041]

[0042] Table 1-2. Structural parameters of samples used for welding crack sensitivity test of embodiment 1-8

[0043]

[0044] Adopt the sample that is used for welding crack sensitivity test of embodiment 1-8 to carry out welding crack sensitivity test, concrete steps are as follows:

[0045] (1) Using the same welding method and electrode under the same welding process conditions, the welding grooves of the samples used for the welding crack sensitivity test in Examples 1-8 were respectively w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com