PE temperature difference film and medical head bag prepared by using the pe temperature difference film

A head bag, temperature difference technology, applied in the fields of medical science, bandages, synthetic resin layered products, etc., can solve the problems of virtual sealing, deformation and flatness of the sealing, and pollution of medical products inside, so as to achieve uniform transfer of the adhesive layer and meet the safety requirements. The effect of opening and ensuring flatness

Active Publication Date: 2022-06-03

杭州中诚材料科技有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

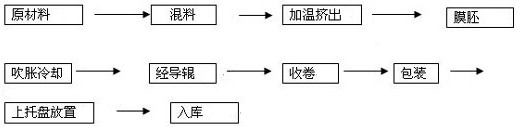

[0002] Plastic flexible packaging materials generally refer to plastic or plastic composite materials, usually soft in texture, and can be used to package goods by making bags, wrapping, etc. The existing temperature difference film has a small temperature difference between the inner and outer layers, so , in the heat-sealing process, when the heat-sealing temperature is high, the sealing part will be deformed and the flatness is poor. It is necessary to design a temperature difference film with a large temperature difference to improve the flatness and firmness of the heat seal during the bag making process

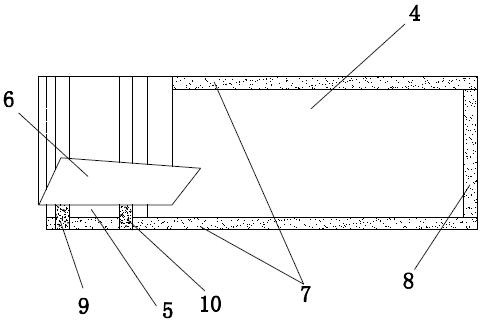

[0003] Header bags are used in the packaging of medical products, such as medical gloves, hemostatic gauze, surgical gowns and protective clothing, etc. The existing header bags usually use Tyvek material to iron the bag body at the peeling port for safe opening. , and the existing head bag usually has uneven transfer of the adhesive layer with small transparent lines and transparent points during the peeling process of the Tyvek-coated paper, or because the seal strength is too high, the Tyvek-coated paper is coated during the peeling process. The gummed paper layer is damaged, and paper dust remains on the glued layer after tearing, which may easily cause contamination of the medical products inside. Therefore, a plug bag is designed to ensure that the coating of Tyvek coated paper is transferred evenly, and the surface is smooth and free of burrs. Needed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

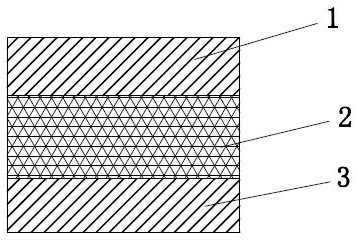

[0033] The PE temperature difference film with a thickness of 60 μm consists of an outer layer with a high melting point with a maximum withstand temperature of 125 ° C, a supporting middle layer,

[0036] Outer layer: 165°C in zone 1, 175°C in zone 2, 185°C in zone 3-4, and 180°C in zone 5-6;

[0038] Inner layer: 150°C in zone 1, 160°C in zone 2, 165°C in zone 3-4, and 160°C in zone 5-6.

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a PE temperature difference film and a medical head bag prepared by using the PE temperature difference film. It is composed of an outer layer, a supporting middle layer and an inner layer. The temperature resistance of the outer layer is 15-20°C higher than that of the inner layer. The thickness of the PE temperature difference film is 60 ‑90μm, the thickness of the outer layer accounts for 27‑30% of the film thickness, the thickness of the supporting middle layer accounts for 36‑40% of the film thickness, and the thickness of the inner layer accounts for 27‑30% of the film thickness. The top bag includes the upper bag body and the lower bag body made of PE temperature difference film, and Tyvek glued paper. The glued paper is connected with the upper bag body and the lower bag body through side seal and bottom seal. There is a temperature difference of 15‑20°C between the inner and outer layers of the temperature difference film to ensure the flatness and firmness of the side seal; the head bag prepared by using the temperature difference film can realize Tyvek glued paper glass without paper scraps and fibers The adhesive layer transfers evenly and meets the requirements of safe opening.

Description

PE temperature difference film and medical plug bag prepared by using the PE temperature difference film technical field The invention belongs to the technical field of packaging materials, be specifically related to PE temperature difference film and adopt the medical equipment prepared by this PE temperature difference film Head bag. Background technique [0002] Plastic flexible packaging material generally refers to the composition of plastic or plastic composite materials, usually soft texture, can pass through The packaging of goods is realized by bag making, wrapping, etc. The existing temperature difference film has a small temperature difference between the inner and outer layers. During the sealing process, it is easy to occur that when the heat sealing temperature is high, the sealing area is deformed and the flatness is poor. It is flat, but it is very prone to the phenomenon of looseness and virtual sealing. Therefore, a temperature difference film with a ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B32B27/08B32B27/32A61F13/00A61B42/40B29C48/00B29C48/10B29C55/28

CPCB32B27/08B32B27/32B29C55/28B29C48/10B29C48/0017A61B42/40A61F13/00072

Inventor 俞晓康郑飞沈建青

Owner 杭州中诚材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com