Device for eliminating internal stress of paper web

An internal stress, paper web technology, applied in the field of paper web production, can solve the problems of static charge, bending force and stiffness reduction, and achieve the effect of ensuring flatness, recovery performance, and eliminating static charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

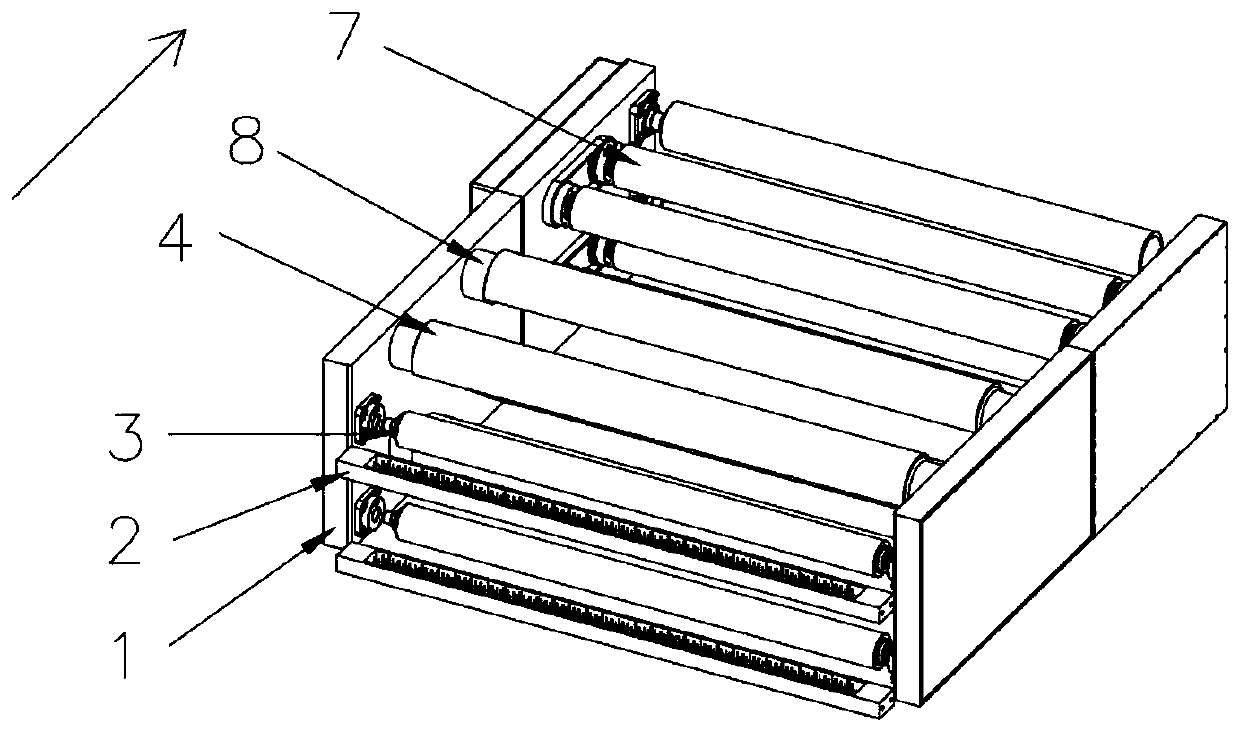

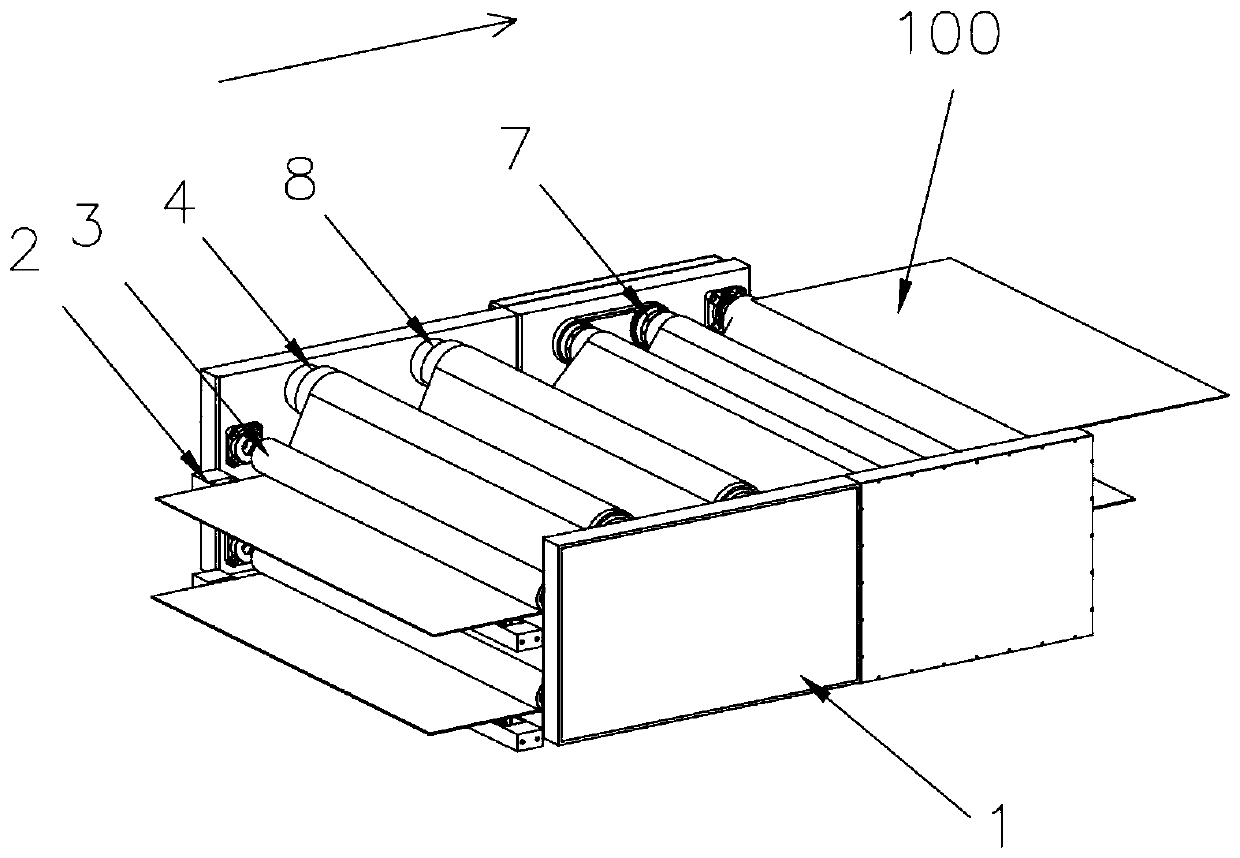

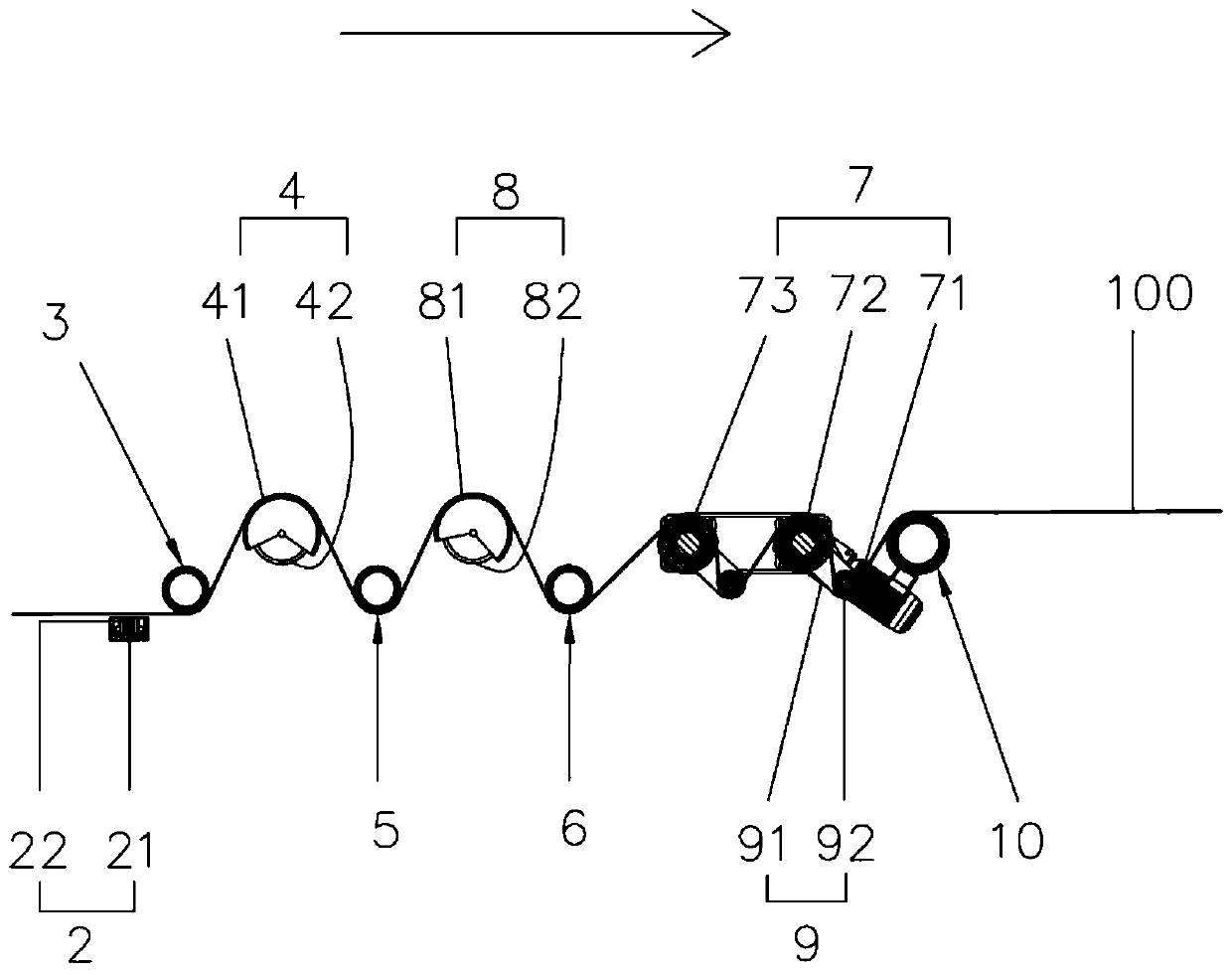

[0034] see Figure 1 to Figure 4 , a device for eliminating the internal stress of the paper web according to the present invention includes a box body 1, and also includes an ion generator 2, an input limit roller 3, a preheating element 4, and an anti-bend Roller 5, output limit roller 6 and drive assembly 7;

[0035] The drive assembly 7 includes a first rotating shaft 71 rotatably connected to the box body 1 and a driving source 72 for driving the first rotating shaft 71 to rotate;

[0036] The anti-bending roller 5 is located below the preheating element 4 and the output limiting roller 6;

[0037] The single paper in the external paper web is driven by the driving source 72 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com