Jacket of a riprap system and its construction process

A jacket and process technology, applied in construction, infrastructure engineering and other directions, can solve problems such as undiscovered, and achieve the effects of convenient welding, high closing precision, and improving welding quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

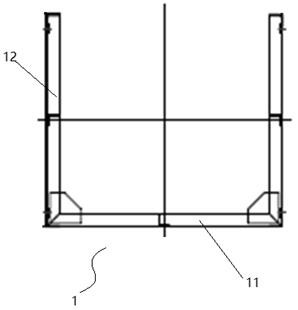

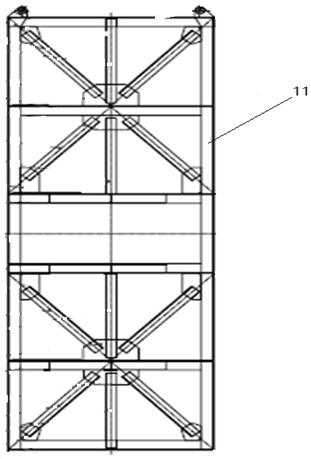

[0049] Such as Figure 1 to Figure 4 The jacket of a riprap system shown includes a jacket frame 1, a box girder structure 2 and a corbel structure; the box girder structure 2 is embedded on the jacket frame 1, and the corbel structure is arranged on the jacket On the overall structure formed by the frame 1 and the box girder structure 2.

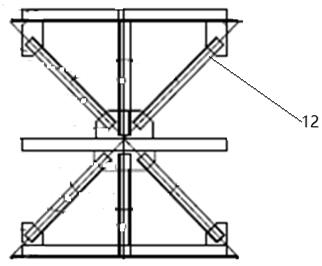

[0050] The jacket frame 1 includes a transom plate 11, a port and starboard plate 12 and an end plate frame; the port and starboard plates 12 are vertically arranged on both sides of the transom plate 11 to form a U-shaped structure; the end plates The racks are arranged at both ends of the U-shaped structure.

[0051] The box beam structure 2 includes a port box structure 21, a starboard box structure 22, a bottom box structure 23 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com