High-efficiency water turbine

A water turbine, high-efficiency technology, applied in mechanical equipment, hydroelectric power generation, engine components, etc., can solve problems affecting the efficiency of water turbines, lack of hydraulic power, etc., and achieve high power generation efficiency and save investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

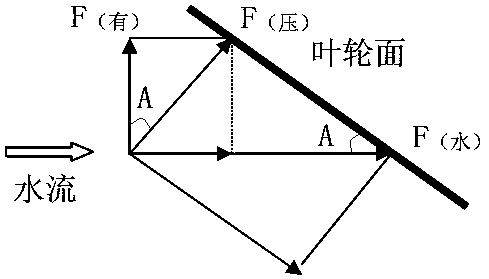

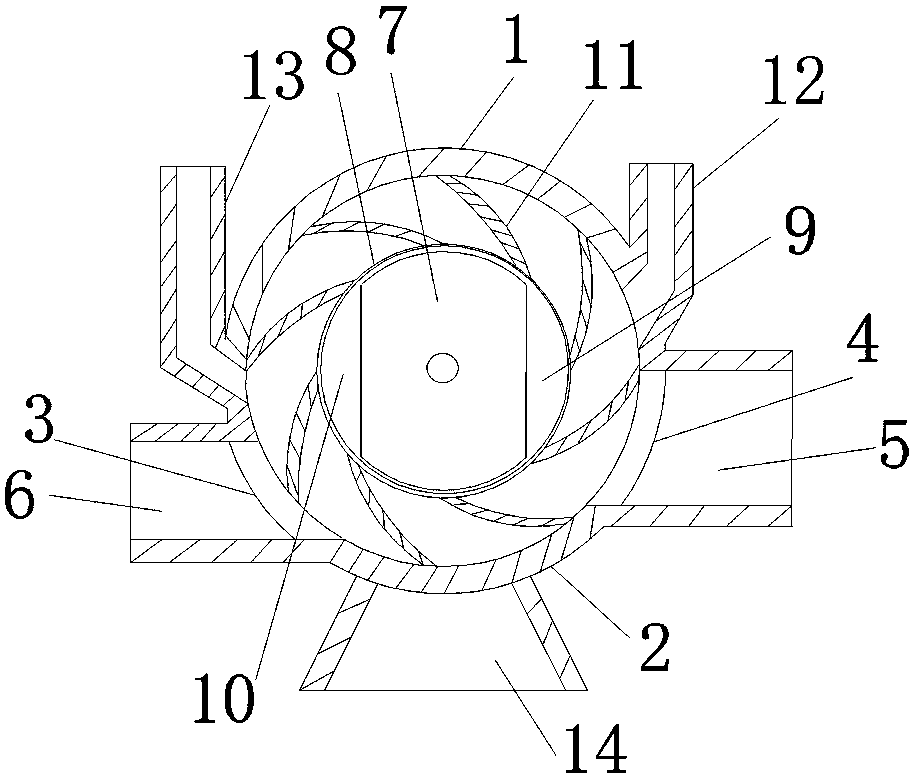

[0027] Such as figure 2As shown, the high-efficiency water turbine involved in the present invention includes a pump casing, and the pump casing includes an upper end cover 1, a lower end cover 2, a first transition connection plate 3, a second transition connection plate 4, a front side plate and a rear side plate, Wherein at least part of the upper end cap 1 is arc-shaped, at least part of the lower end cap 2 is also arc-shaped, and the radius of the arc-shaped upper end cap 1 is equal to the radius of the arc-shaped lower end cap 2, which is an arc The upper end cover 1 part and the arc-shaped lower end cap 2 are concentric circles, and the two ends of the arc-shaped upper end cap 1 and the arc-shaped lower end cap 2 respectively go through the first transition The connecting plate 3 and the second transitional connecting plate 4 are connected together; a water inlet or a water outlet is provided on the first transitional connecting plate 3, and a water outlet or a water i...

Embodiment 2

[0039] In this embodiment, there is no fixed shaft, and the stator 7 is sleeved on the rotating shaft. The stator 7 keeps the position of the stator 7 relatively fixed by relying on the gravity block in the stator 7 or mechanical and electronic methods. The rotating shaft runs through the The front circular plate and the rear circular plate of the rotor, and the front circular plate and the rear circular plate are fixedly connected to the rotating shaft, and the rotating shaft is connected to the front side plate and the rear side plate through bearings or sliding sleeves ; The rotating shaft is used for external generator. The rest of the structure of the water turbine is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com