Dust, paint mist and lampblack exhaust gas purification exhaust fan

A technology of exhaust gas purification and exhaust fan, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc. It can solve the problems of shaking and vibration, short service life, and unstable operation, so as to avoid shaking and vibration and have a long service life , running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

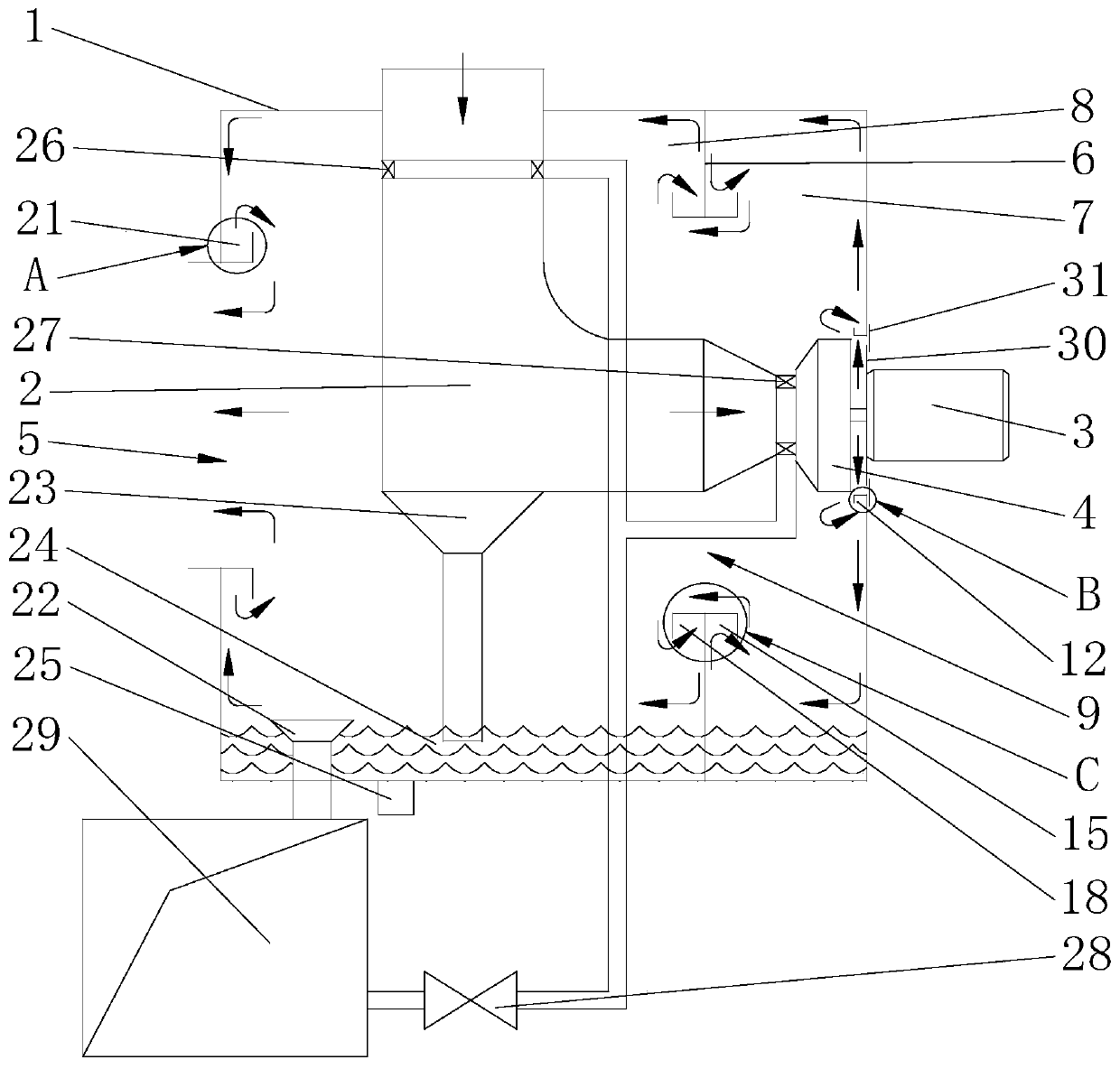

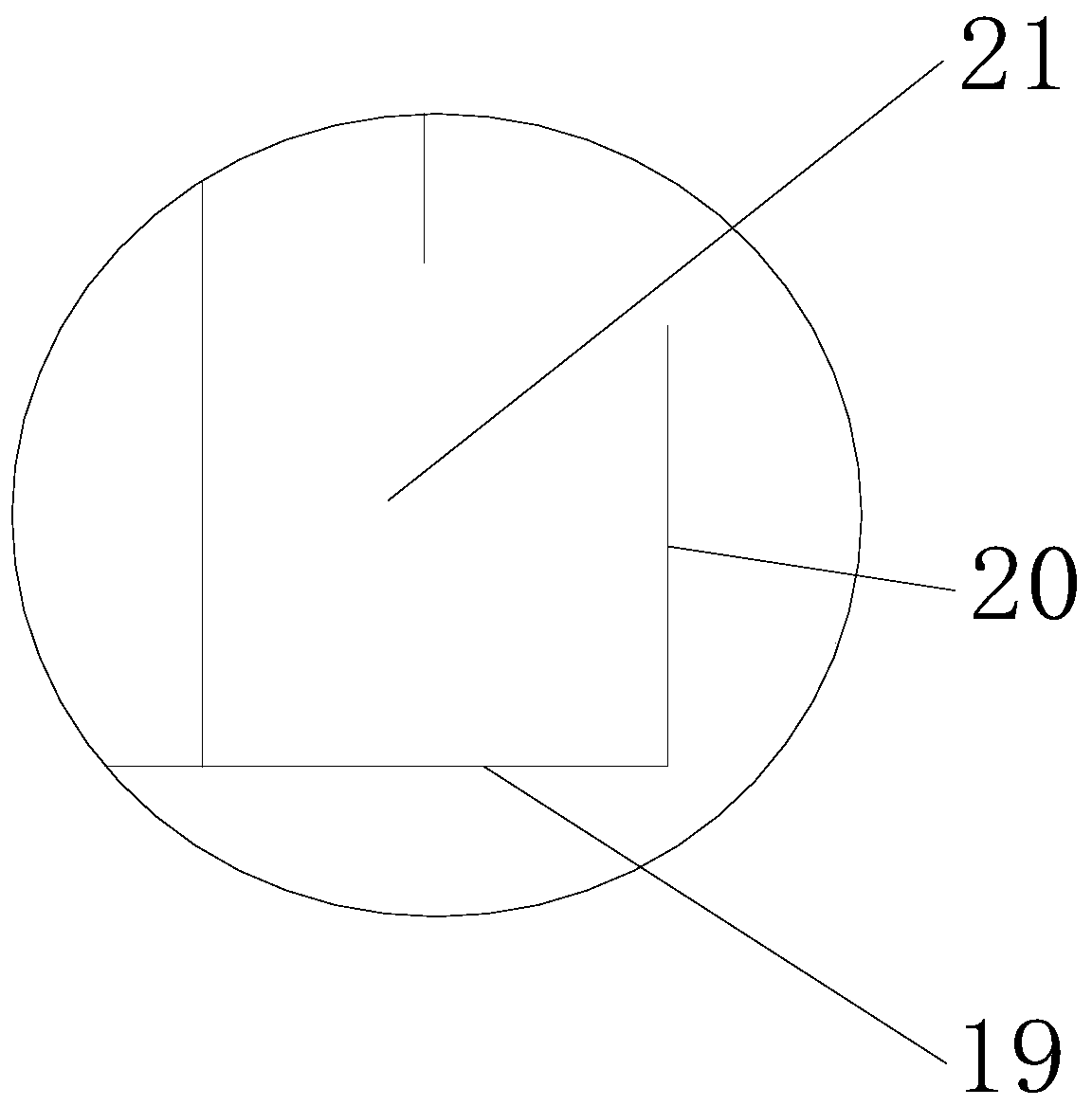

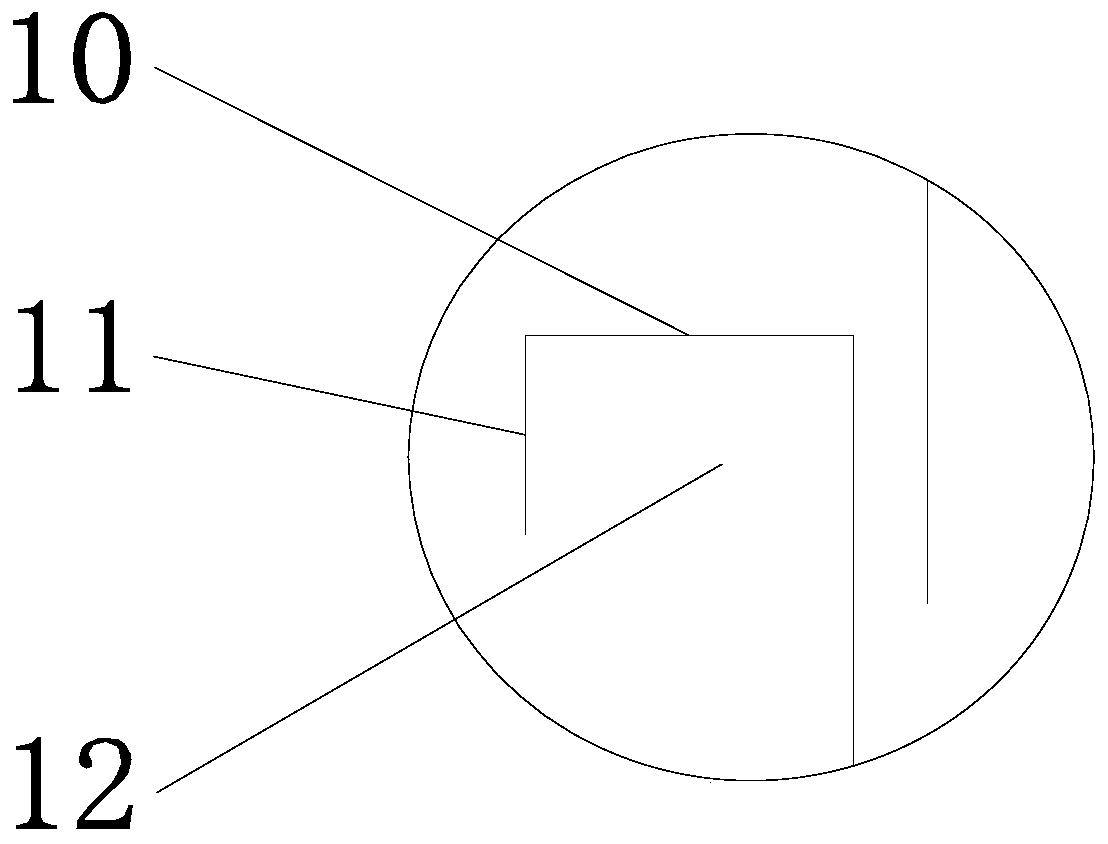

[0021] Below in conjunction with accompanying drawing, the present invention will be further described, see Figure 1~4 As shown, the present invention comprises an organic casing 1, an air inlet pipe 2, a motor 3, and a wind wheel 4. The upper half of the casing 1 is semicircular, and the lower half of the casing 1 is an inverted trapezoid. The pipe 2 is arranged in the inner cavity of the casing 1, the wind wheel 4 is arranged in the inner cavity of the casing 1 and its air outlet end is close to the rear side wall of the inner cavity of the casing 1, and the air inlet of the air inlet pipe 2 passes through the machine upwards. The top of the shell 1 communicates with the outside, the air outlet of the air inlet pipe 2 bends backwards and extends to the air inlet end of the wind wheel 4, the air outlet of the air inlet pipe 2 communicates with the air inlet end of the wind wheel 4, the air inlet pipe 2 The air outlet forms a trumpet-shaped structure with a large front and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com