A Parallel Damping Stability Maintenance Vibration Reduction Energy Harvesting Device

A parallel and damping technology, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of single vibration damping function and the inability to realize vibration energy collection, etc., and achieve good damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

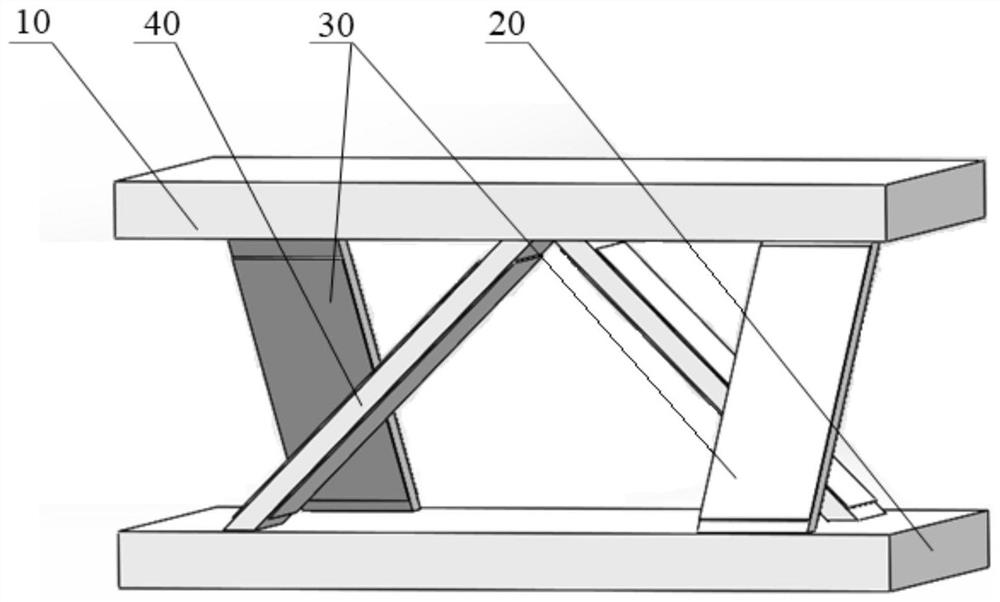

[0026] A kind of parallel damping stability maintenance vibration reduction energy harvesting device of this embodiment, such as figure 1 As shown, it includes a first backing plate 10, a second backing plate 20, an energy collector 30, and several vibration-damping support frames 40; the first backing plate 10 is set opposite to the second backing plate 20, and the vibration-damping support frame 40 is located on the Between the first backing plate and the second backing plate, all the vibration-damping support frames are arranged in a spatially orthogonal manner; the energy collector 30 is installed on the vibration-damping support frame for linkage with it.

[0027] The vibration-damping support frame 40 is made of rubber and has a certain mechanical strength. It has a certain damping effect on bending deformation and twisting deformation. When it is excited, it will not break or break. In this example, the vibration-damping support frame 40 has a rectangular plate-like str...

Embodiment 2

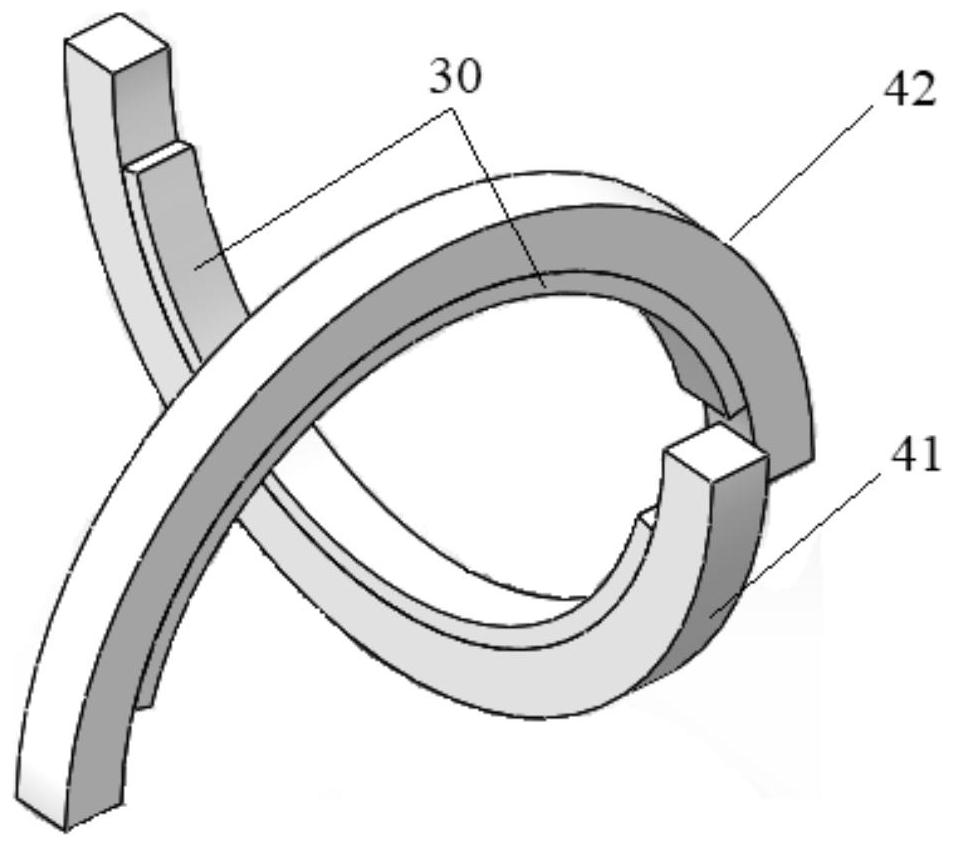

[0031] The difference between the parallel damping, stability maintenance, vibration reduction and energy harvesting device of this embodiment and the first embodiment is that the vibration damping support frame 40 is a semi-circular structure.

[0032] like figure 2 As shown, the vibration-damping support frames of the two semi-circular structures form a group, which are arranged in opposite directions, and the projections on the installation plane form an included angle of 90°; wherein the two ends of the first vibration-damping support frame 41 are plugged into the second In the slot of the backing plate, the piezoelectric sheet 30 is pasted on one side of the inner arc, and the arc top on the outer arc side is pasted and fixed on the first backing plate; the two ends of the second damping support frame 42 are inserted into the first backing In the slot of the board, a piezoelectric sheet 30 is pasted on one side of the inner arc, and the arc top on the side of the outer a...

Embodiment 3

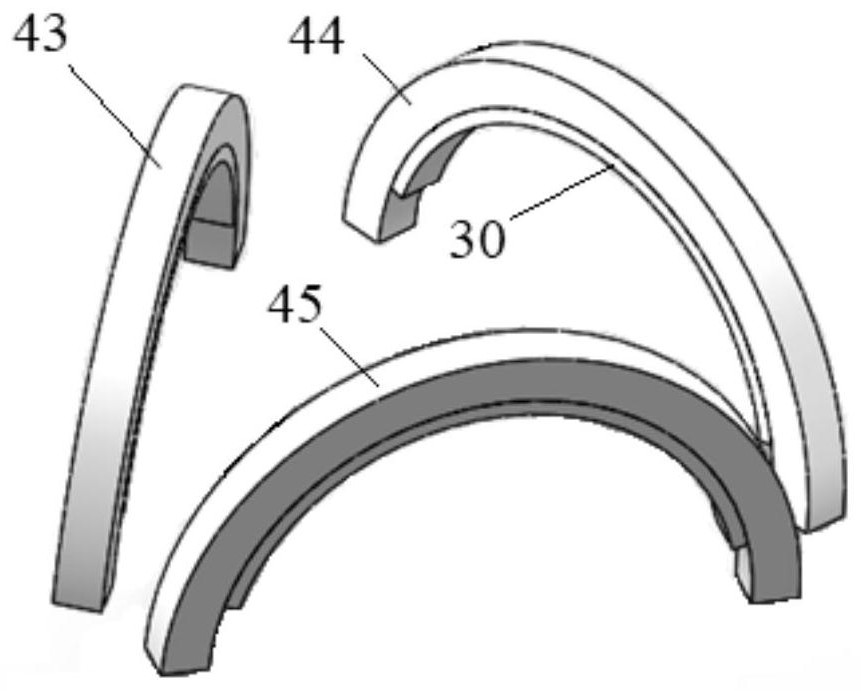

[0035] The difference between the parallel damping, stability maintenance, vibration reduction and energy harvesting device of this embodiment and the second embodiment lies in that the vibration-damping support frame of the semi-circular structure is distributed in the circumferential direction.

[0036] like image 3 As shown, three vibration-damping support frames form a group, which are respectively a first vibration-damping support frame 43 , a second vibration-damping support frame 44 and a third vibration-damping support frame 45 . Both ends of the first vibration-damping support frame, the second vibration-damping support frame and the third vibration-damping support frame all have plug joints, are installed in the slots of the second backing plate, and one side of the inner arc is pasted with a piezoelectric sheet 30 , the arc top on one side of the outer arc is pasted and fixed on the first backing plate. The first vibration-damping support frame, the second vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com