Non-metal pipeline leakage positioning method based on inverse transient analysis method

A technology for pipeline leakage and positioning methods, which can be applied to pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., and can solve problems such as insufficient calculation accuracy and slow calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

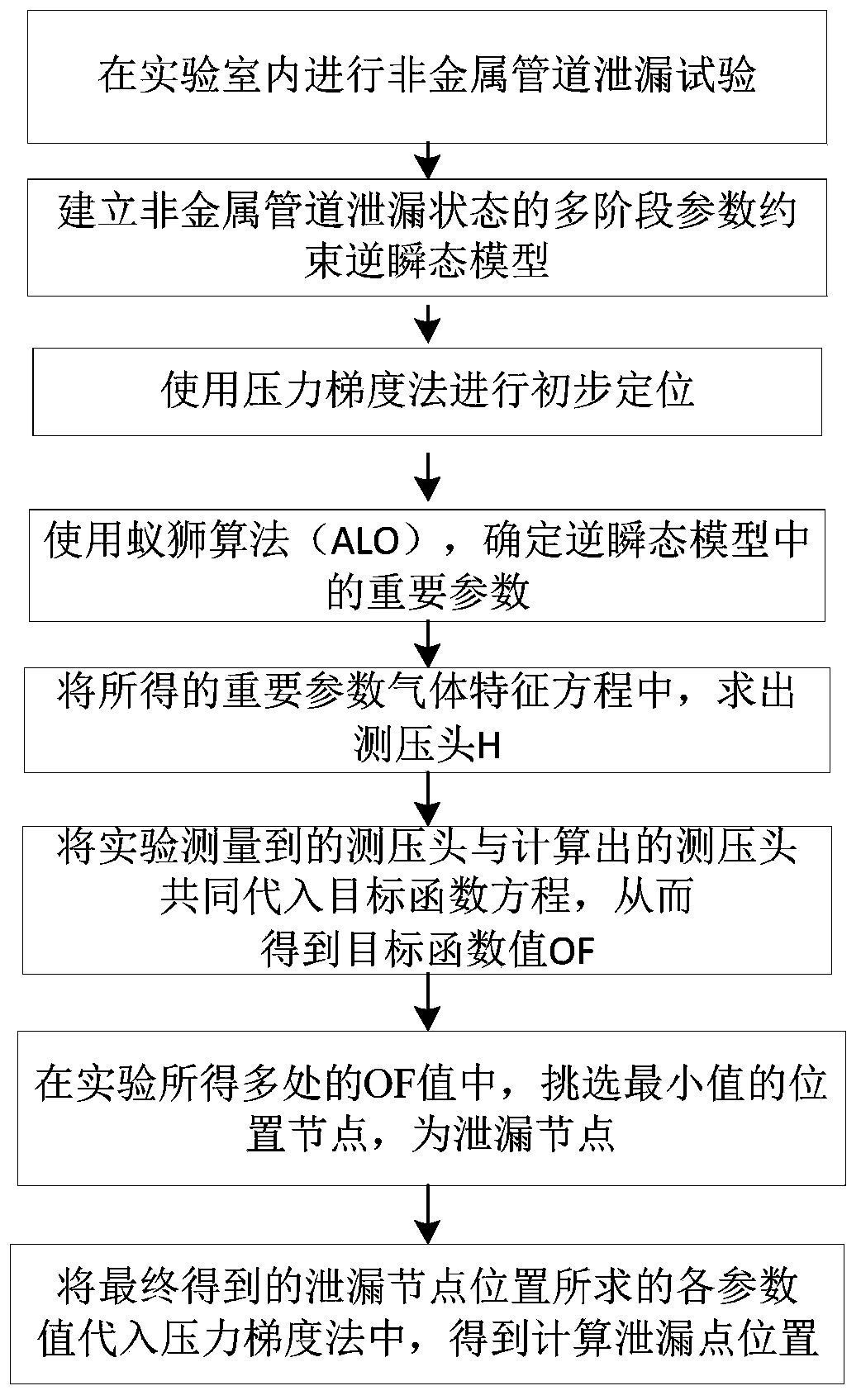

[0060] Such as figure 1 As shown, a non-metallic pipeline leakage location method based on the inverse transient analysis method of the present invention comprises the following steps:

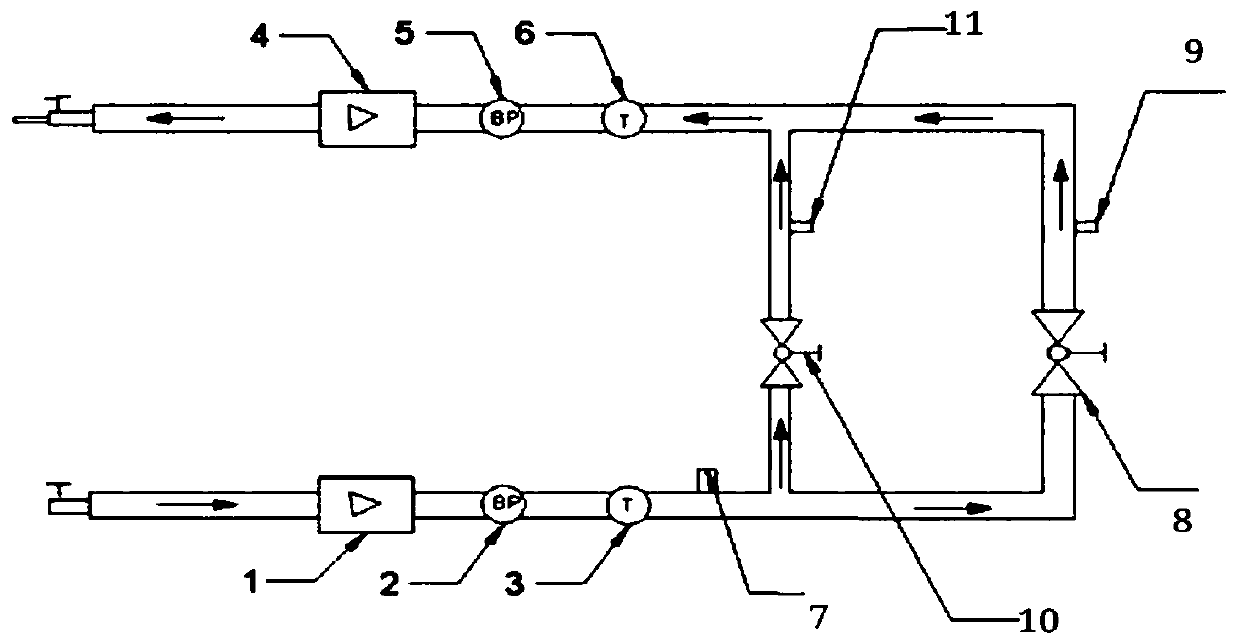

[0061] S1: Build in the laboratory such as image 3 The non-metallic pipeline model with a total length of 7.9 meters is shown, the pipeline type is ground pipeline, and the transmission medium is air. The upstream leakage valve 7 is determined to simulate the leakage point I, and the downstream leakage valve 9 is determined to simulate the leakage point II, respectively, 2.50m away from the air inlet. 4.15m. Install upstream vortex flowmeter 1 and downstream vortex flowmeter 4, upstream pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com